Winder of depth measurer

A technology of depth measuring instrument and winding device, which is applied in the direction of measuring device, lubrication indicating device, liquid/fluid solid measurement, etc., which can solve the problems of high price, time-consuming and labor-intensive test results easily affected by environmental parameters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

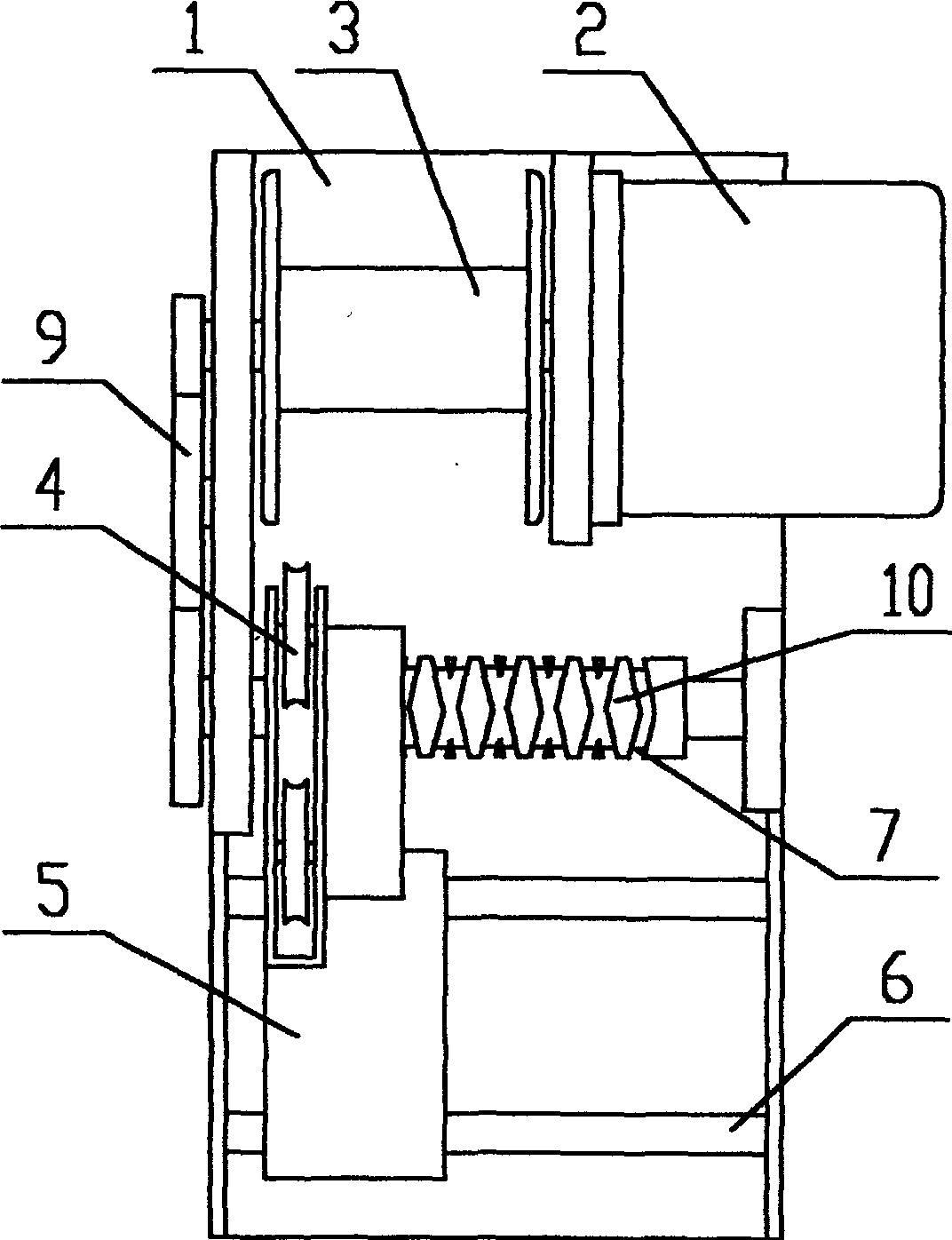

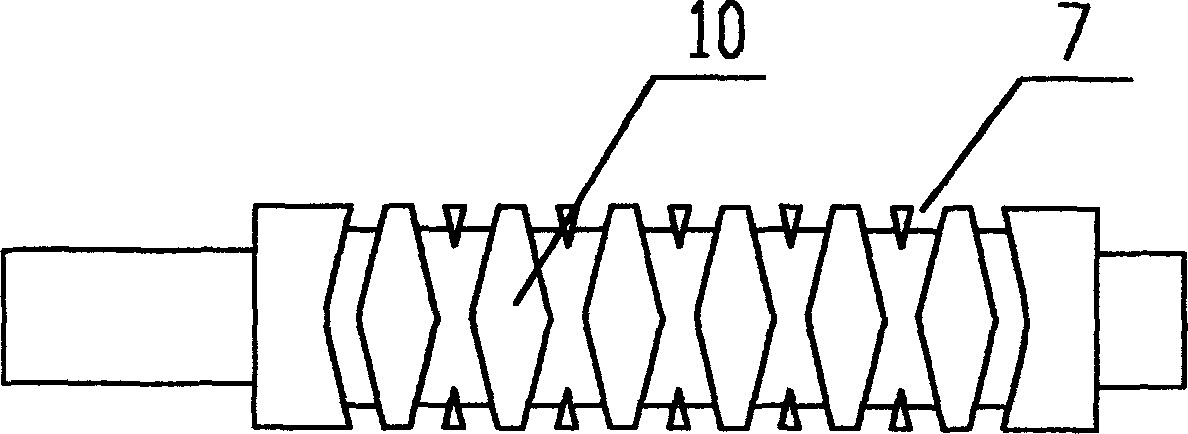

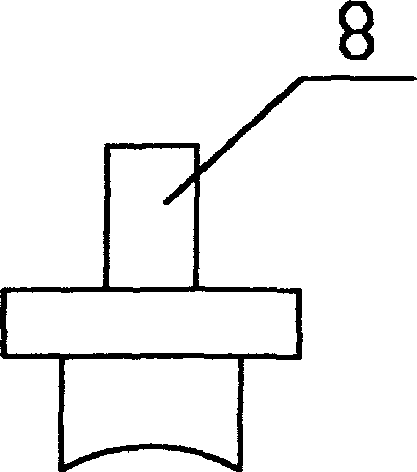

[0010] as attached figure 1 , attached figure 2 , attached image 3 As shown, the winding device of the depth measuring instrument comprises a base 1, a stepping motor 2 installed on the base 1, the stepping motor 2 drives the winding wheel 3 to rotate, and the wire guide device evenly winds the wire on the winding wheel 3 Above, the wire guide device includes a wire grab 4, the wire grab 4 is fixed on the base 5, and the structure of the wire grab 4 is a runner with a wire groove in the middle, which can prevent the wire from jumping out; the base 5 can slide along the guide rail 6 parallel to the axis of the reel 3, while the base 5 can move evenly along the guide shaft 10 parallel to the axis of the reel 3, the outer surface of the guide shaft 10 is provided with forward and reverse spiral grooves 7, The ends of the forward and reverse spiral grooves 7 are smoothly connected, and the guide block 8 on the base 5 is inserted into the spiral groove 7. When the guide shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com