Oil supply structure for hermetic vortex type compressor

A scroll compressor and oil supply technology, which is applied in the field of compressors, can solve the problems of insufficient supply of oil and reduce the starting efficiency of the motor, etc., and achieve the effect of good distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

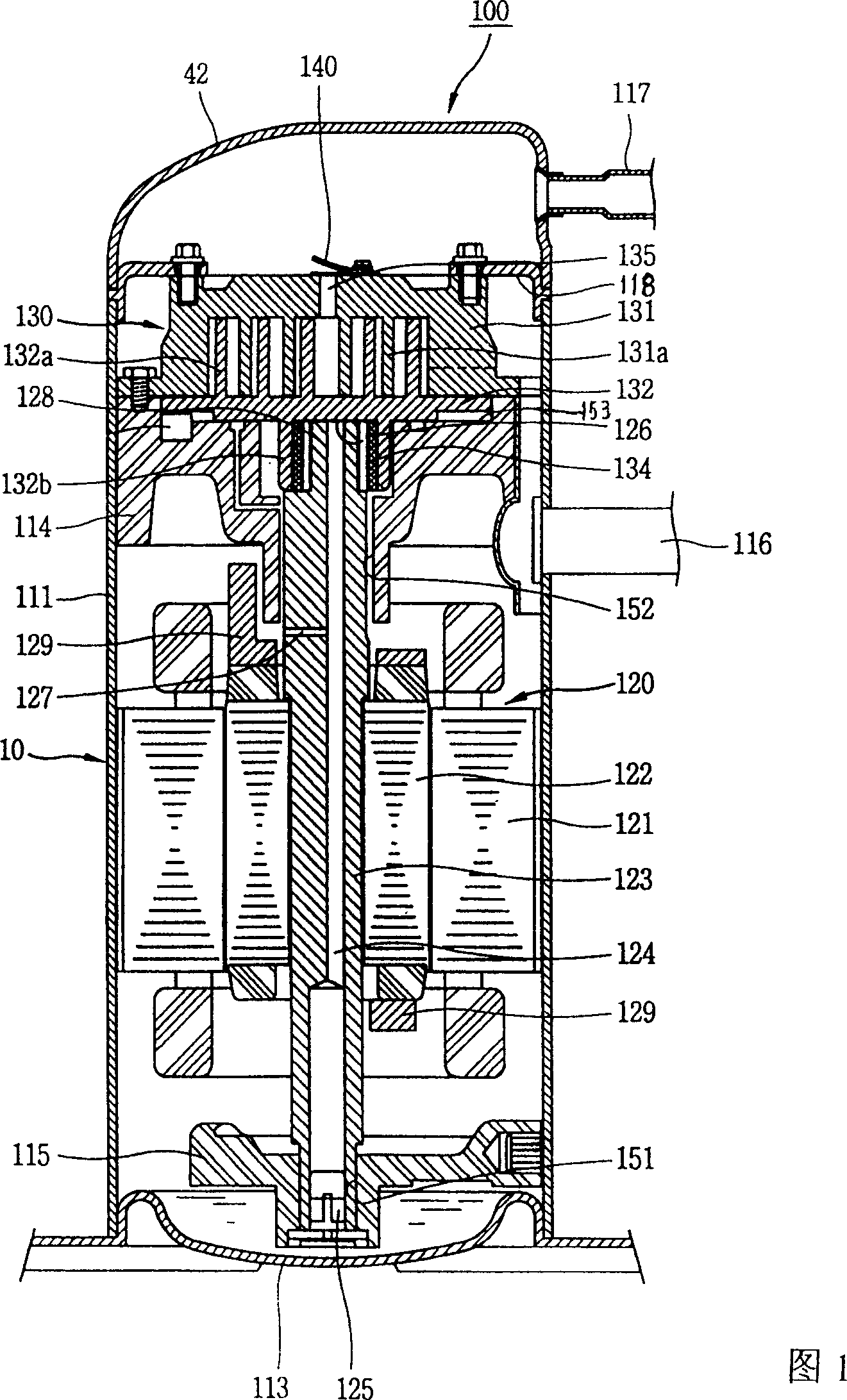

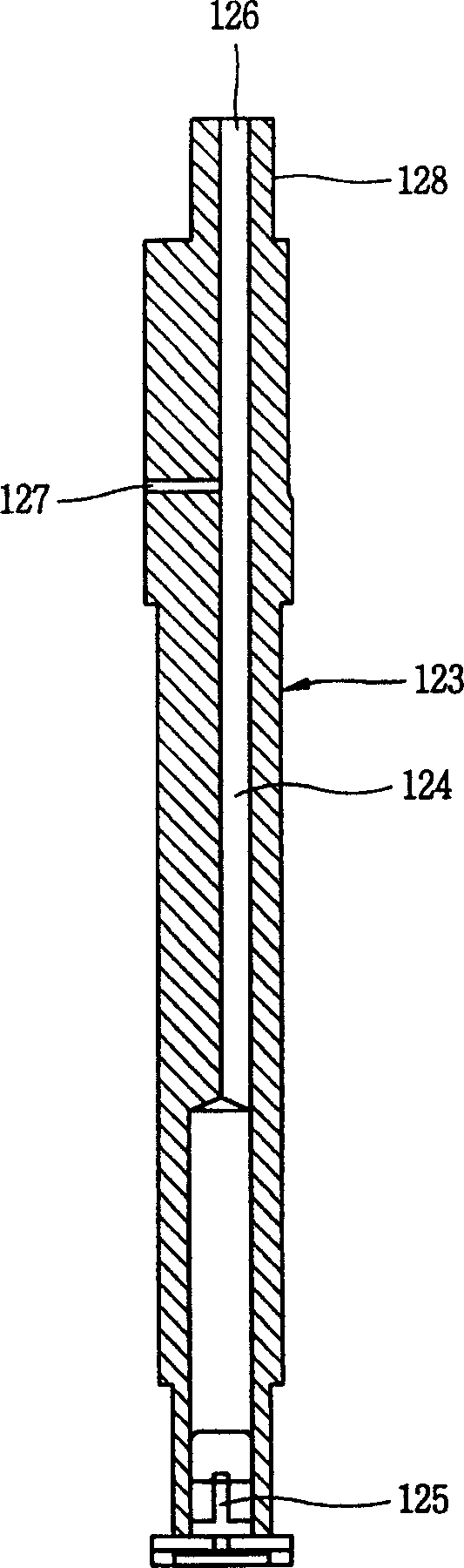

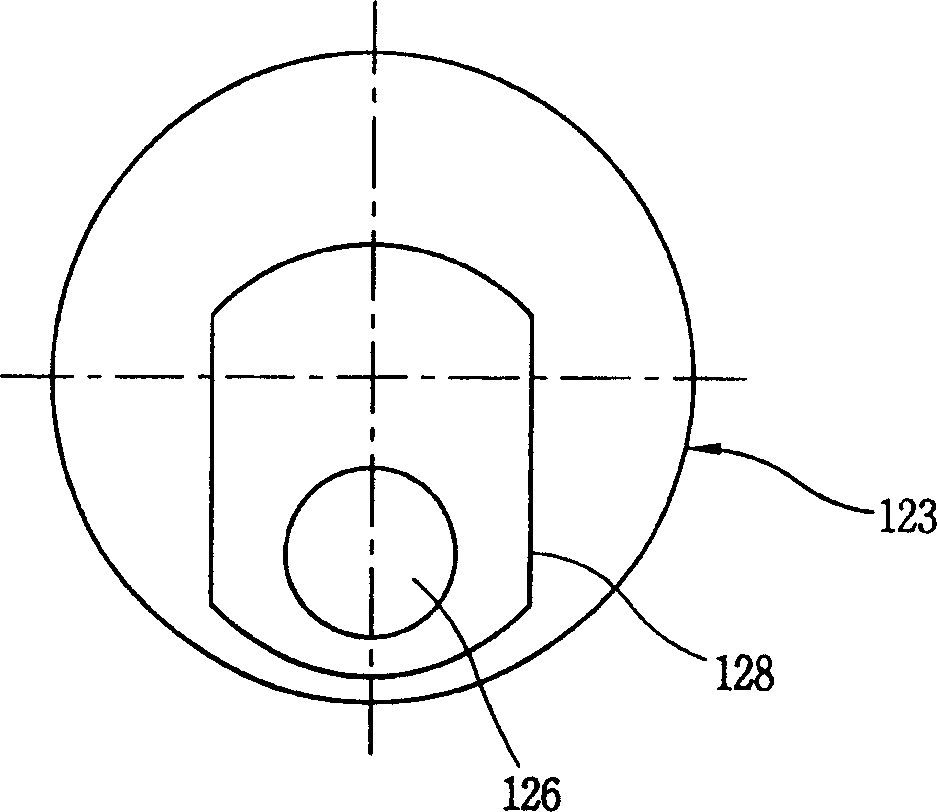

[0058] The oil supply structure of the sealed scroll compressor will be described below with reference to the accompanying drawings.

[0059] As shown in the figure, the scroll compressor (1) in the present invention consists of the following parts. That is, the casing (10) that forms a sealed space inside; the compressor (30) that compresses the refrigerant inside the casing (10); the motor (20) that provides power to the compressor (30); The main frame (14) and the auxiliary frame (15) etc. which support the rotation shaft (23) of the motor (20) up and down.

[0060] Shell (10) is made up of following several parts. That is, a cylindrical housing main body (11) with openings at the upper and lower ends; an upper end cover (12) that seals the top of the housing and is connected with the housing main body; a lower end cover (13) that seals the lower end of the housing and is connected with the housing main body (11) )Wait.

[0061] The compressor (30) consists of a fixed sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com