Noise reducing device for vortex type compressor

A scroll compressor, noise technology, applied in the field of equipment to reduce the discharge noise of the scroll compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail with reference to accompanying drawing as follows:

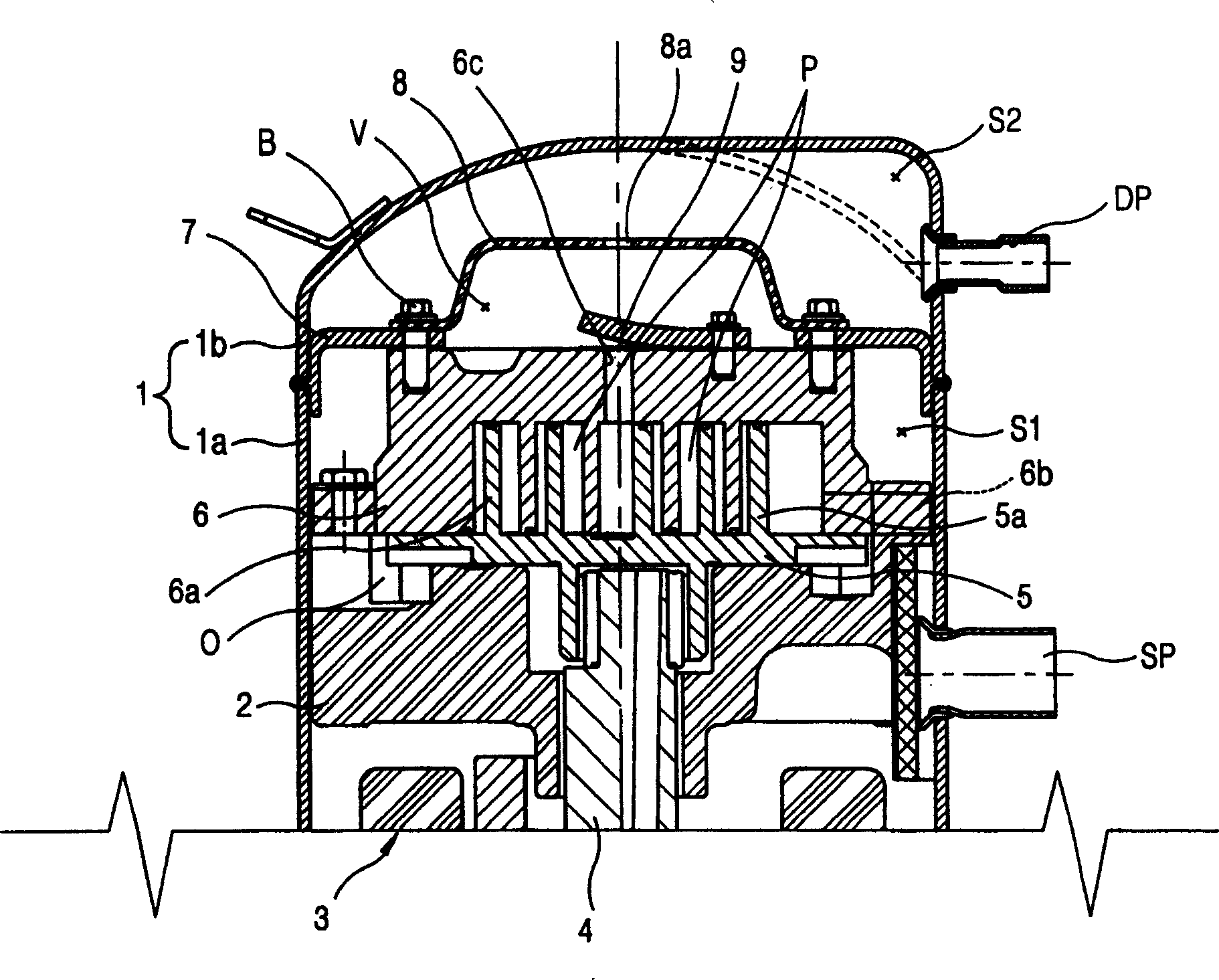

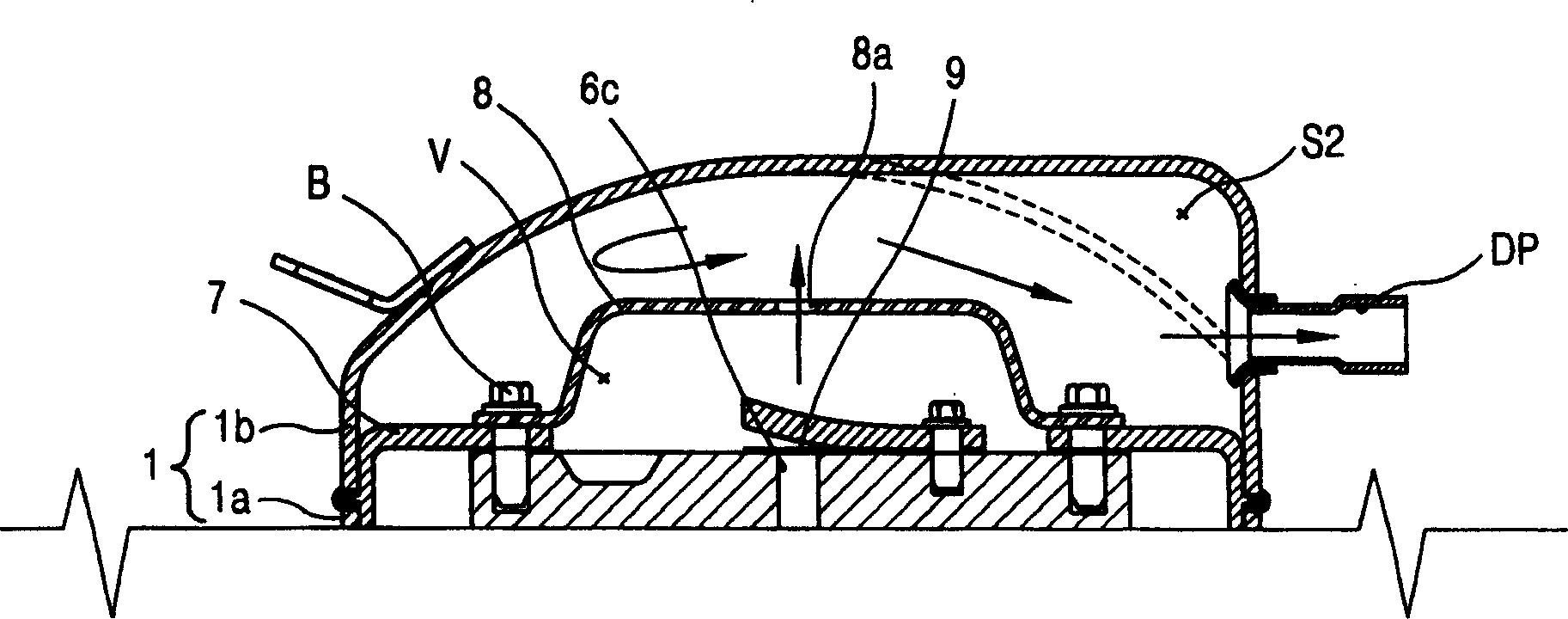

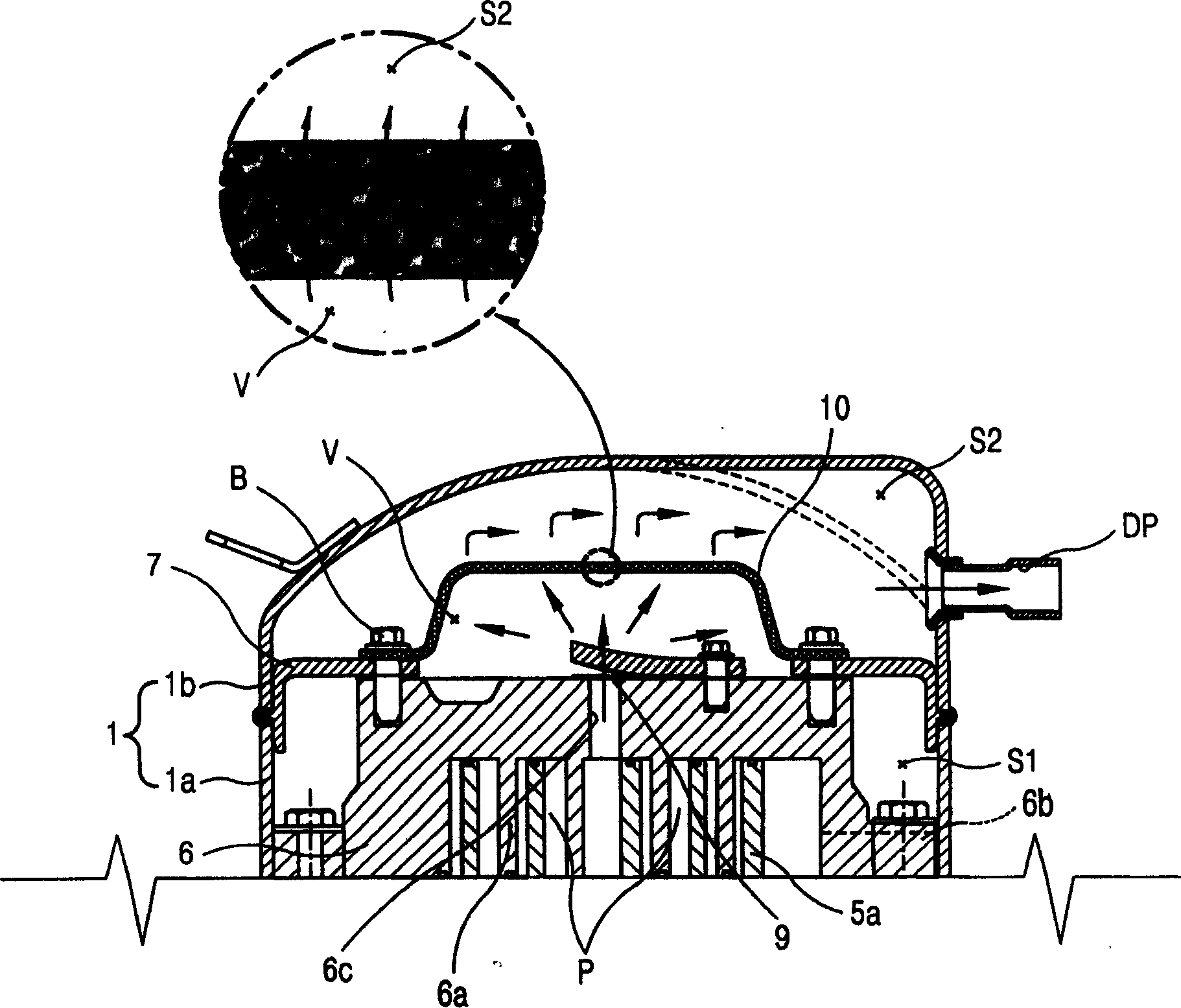

[0026] Such as figure 1 , 2 Shown in and 3, a kind of device that reduces the discharge noise of scroll compressor comprises: the sealed housing (1) of scroll compressor, is provided with gas suction pipe on the lower housing (1a) of sealed housing (1) (SP), the upper casing (1b) of the sealed casing (1) is provided with a gas discharge pipe (DP), and the main frame (2) and auxiliary frame (not shown) are respectively fixed on the sealed casing (1) The upper and lower sides of the interior; the drive motor (3) is installed between the main frame (2) and the auxiliary frame (not shown), and is pressed into the center of the rotor of the drive motor (3), thereby penetrating the main frame (2 ) of the drive shaft (4) of the drive motor (3); the movable scroll (5) is located on the main frame (2) and fixed together with the drive shaft (4), and the scroll (5a) of the movable ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com