Refractory ceramic filtering element for hot gas purification and method for preparing the same

A technology for high-temperature ceramics and filter elements, which is applied in the field of high-temperature ceramic filter elements for hot gas purification, can solve the problems of unsuitable products for industrialization promotion and application, high manufacturing cost, poor thermal stability, etc. Good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

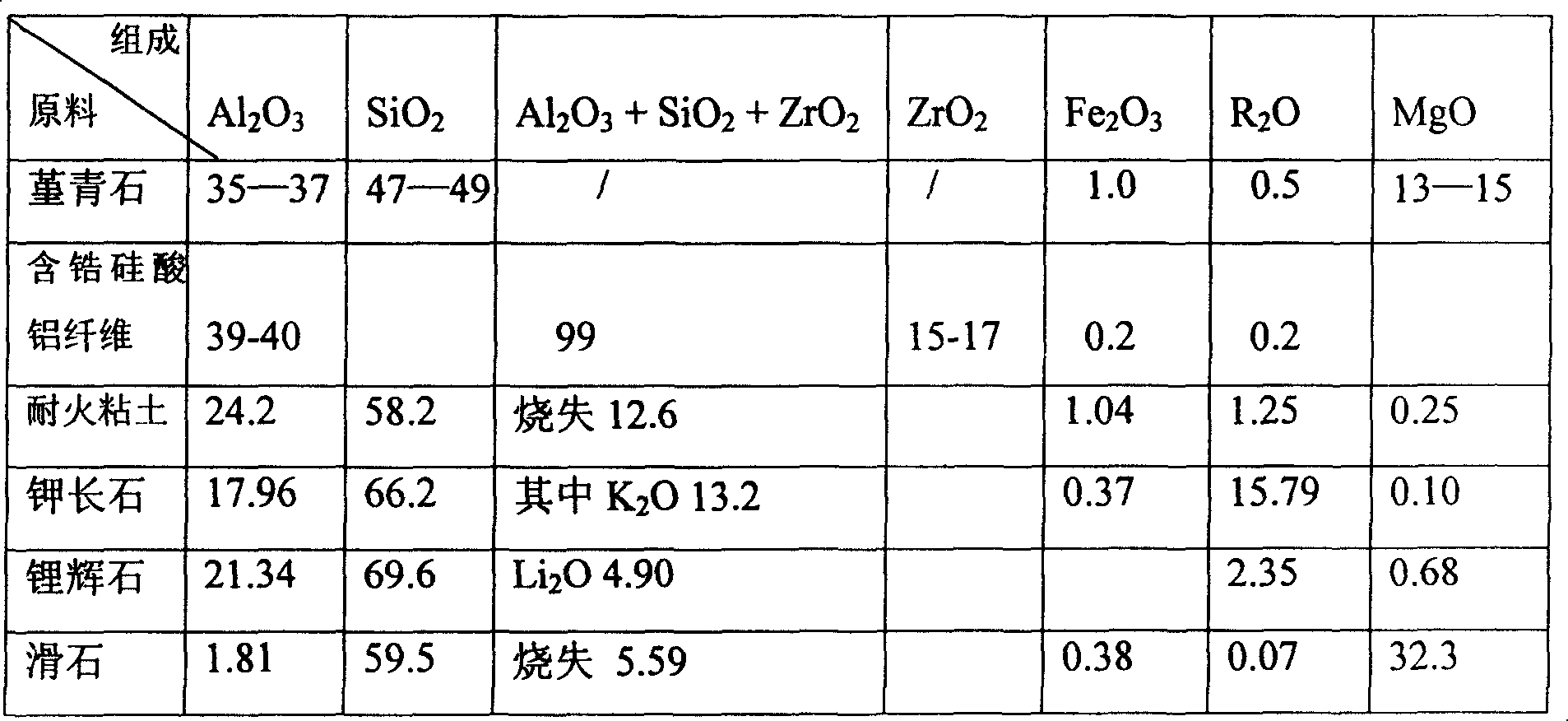

[0032] The composition of the raw materials used in the test is shown in Table 1.

[0033] Table 1. Raw material chemical weight percentage composition list used in the test

[0034]

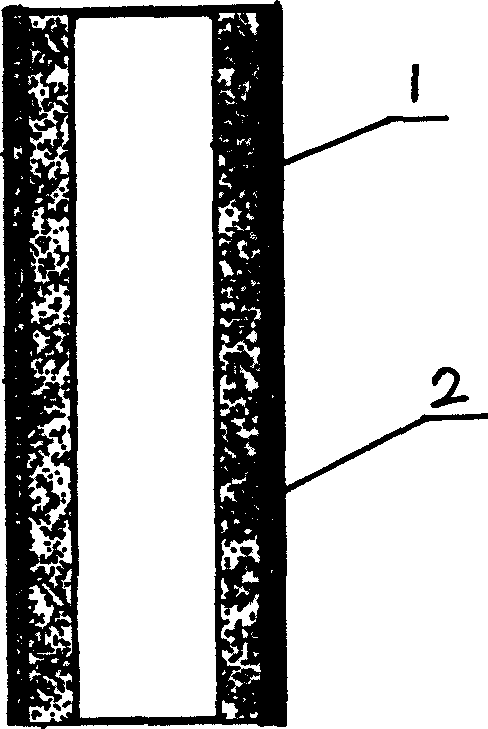

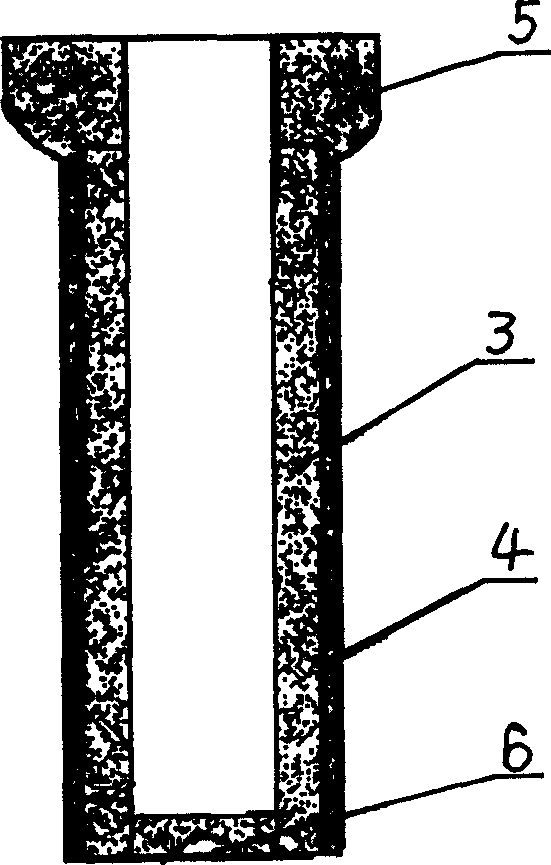

[0035] The high-temperature ceramic filter element for hot gas purification according to the present invention is tubular, and the weight proportion percentage of the ceramic support body is composed of: 73% of commercially synthesized cordierite aggregate with a particle diameter of 200-400um, 23% of high-temperature ceramic binder and granular 4% charcoal pore-enhancing agent with a diameter of 100-200 μm; the weight percentage of the high-temperature ceramic binder is composed of: refractory clay 30%, potassium feldspar 25%, β-spodumene 35%, talc 10%, fineness Control over 200 mesh sieve.

[0036] The weight ingredients of the ceramic fiber composite membrane are composed of 50% of zirconium-containing aluminum silicate fibers, 20% of cordierite aggregates with a particle size of 80-120um...

Embodiment 2

[0042] In the high-temperature ceramic filter element for hot gas purification according to the present invention, the weight percentage of the ingredients of the ceramic support body is composed of:

[0043] 75% cordierite aggregate with a particle size of 300-500μm, 18% high-temperature binder, and 7% pore-enhancing agent;

[0044] Wherein, the composition weight percent of the high-temperature binder is as follows: 30% of refractory clay, 35% of potassium feldspar, 30% of β-spodumene, and 5% of talc.

[0045] The proportioning weight percentage of ceramic fiber composite membrane is composed of:

[0046] 50% zirconium-containing aluminum silicate fiber with a fiber diameter of 6 μm, 25% binder, and 25% cordierite refractory aggregate with a particle size of 80-100 μm;

[0047] Wherein, the composition weight percent of the binder is as follows: 55% of refractory clay, 25% of potassium feldspar, and 20% of talc.

[0048] Preparation:

[0049] Mix and dry the ceramic sup...

Embodiment 3

[0053] In the high-temperature ceramic filter element for hot gas purification according to the present invention, the weight percentage of the ingredients of the ceramic support body is composed of:

[0054] 80% cordierite aggregate with a particle size of 100-600μm, 18% high-temperature binder, and 2% pore-enhancing agent;

[0055] Wherein, the composition weight percent of the high-temperature binder is as follows: 25% of refractory clay, 35% of potassium feldspar, 32% of β-spodumene, and 8% of talc.

[0056] The proportioning weight percentage of ceramic fiber composite membrane is composed of:

[0057] 50% alumina fiber with a fiber diameter of 7 μm, 26% binder, and 24% cordierite refractory aggregate with a particle size of 50-100 μm;

[0058] Wherein, the composition weight percent of the binder is as follows: 60% of refractory clay, 23% of potassium feldspar, and 17% of talc.

[0059] Preparation:

[0060] The ingredients of the ceramic support are mixed and dried, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com