Die developing management system and method

A management system and management method technology, applied in the field of mold development management system, can solve problems such as uncontrolled, undisclosed mold development, and unable to truly reflect product collaboration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

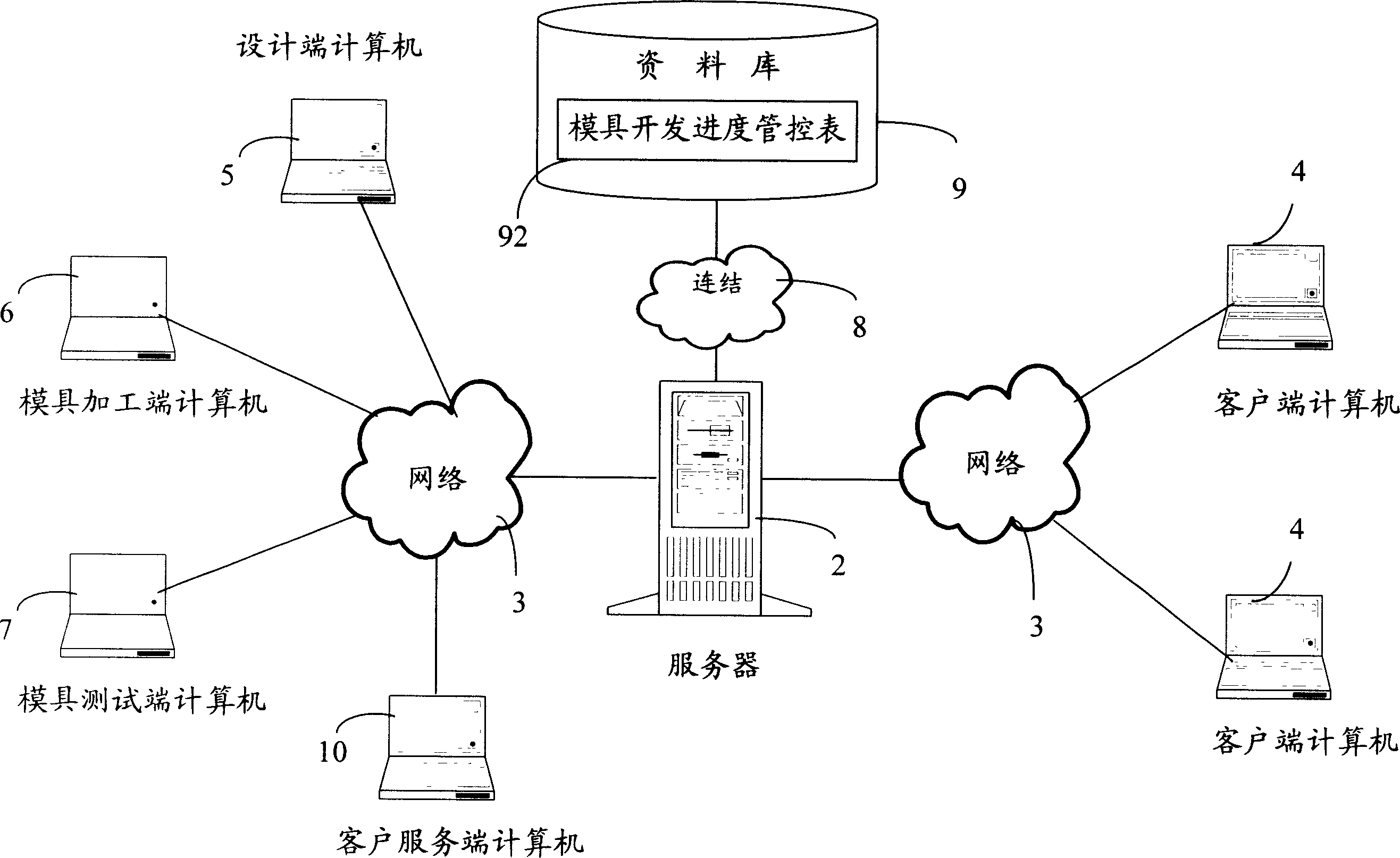

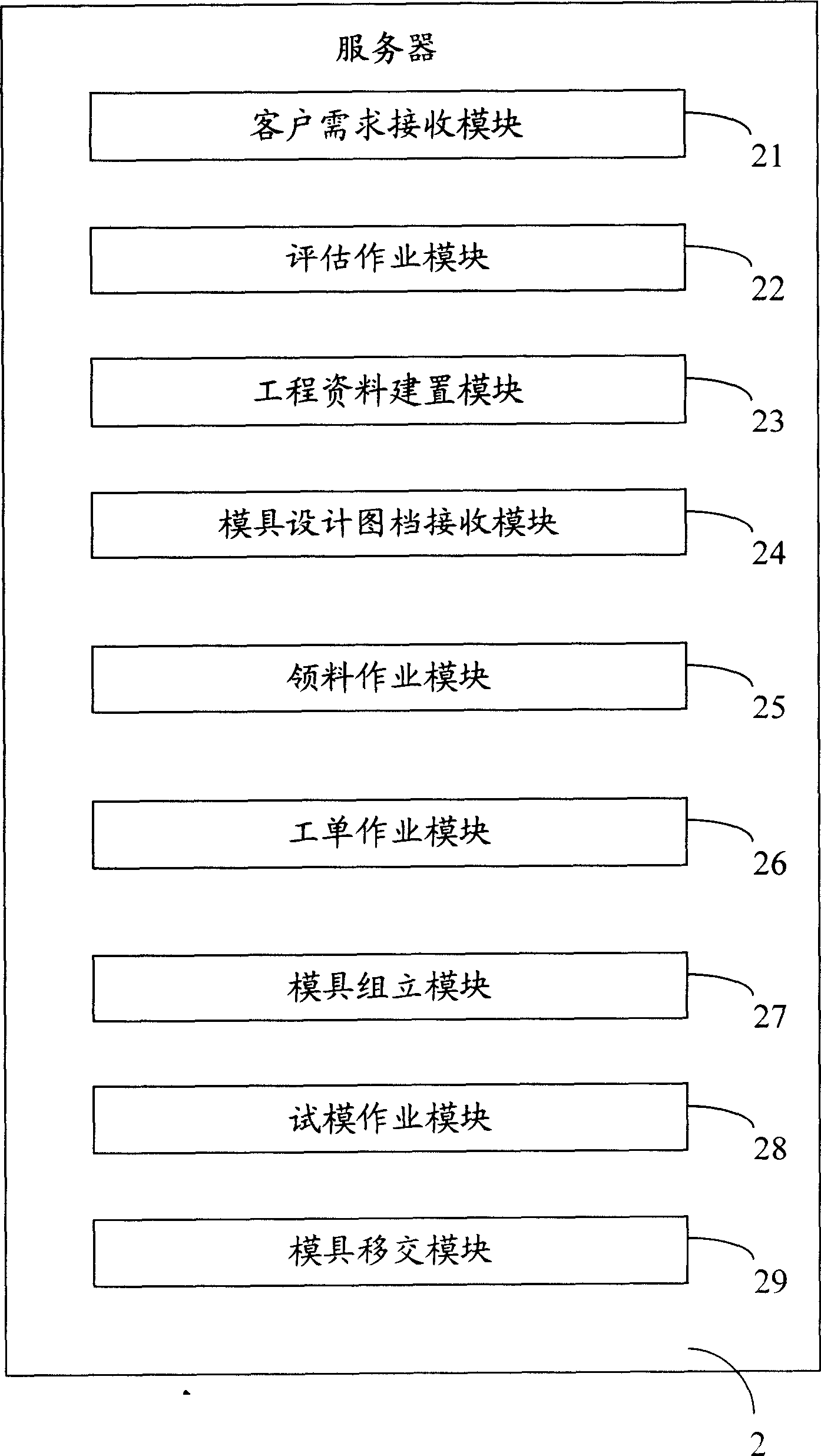

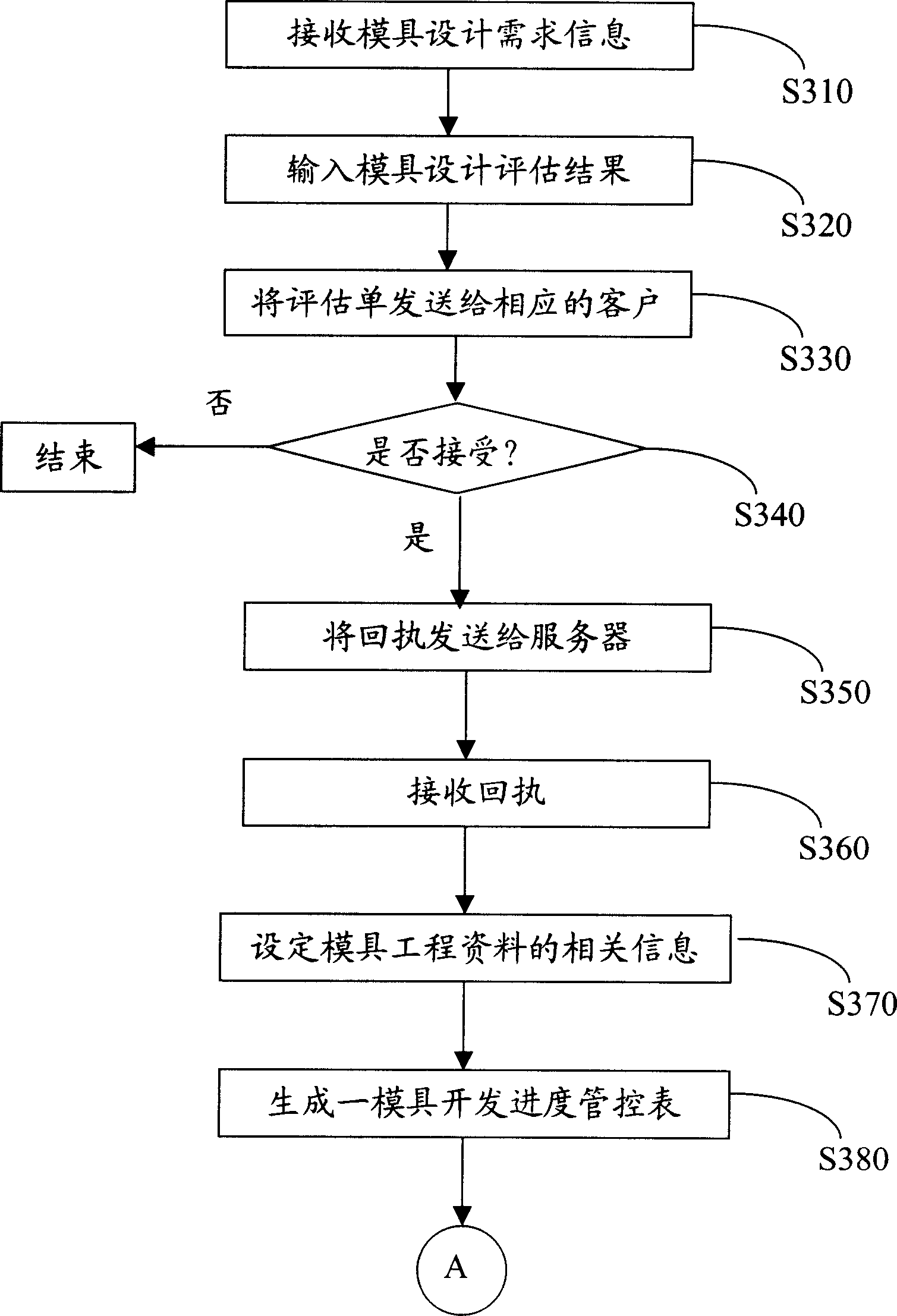

[0014] refer to figure 1 As shown, it is a structure diagram of the mold development management system of the present invention. The mold development management system of the present invention adopts a B / S (Browser / Server) framework to provide a management platform for mold development, which is used to receive the mold design demand information information of multiple customers, and receive the mold design department's request for the aforementioned mold design demand information. Design evaluation and mold design drawings, and control the whole process of mold development. The mold development management system is composed of a server 2 and a plurality of client computers 4 connected to the server 2 through a network 3, a design computer 5, a mold processing computer 6, a mold testing computer 7 and a client server computer 10. .

[0015] Among them, the client computer 4 is placed in the mold design demand information side, and it runs a series of software such as enterpr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com