Conductive rubber and electronic component using same

A technology of electronic components and conductive rubber, applied in electrical components, conductive materials dispersed in non-conductive inorganic materials, conductive materials, etc., can solve the problems of limited use of conductive rubber, inability to generate large current, small cross-sectional area, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The conductive rubber of the present invention and electronic components using the conductive rubber will be further described below in conjunction with the accompanying drawings.

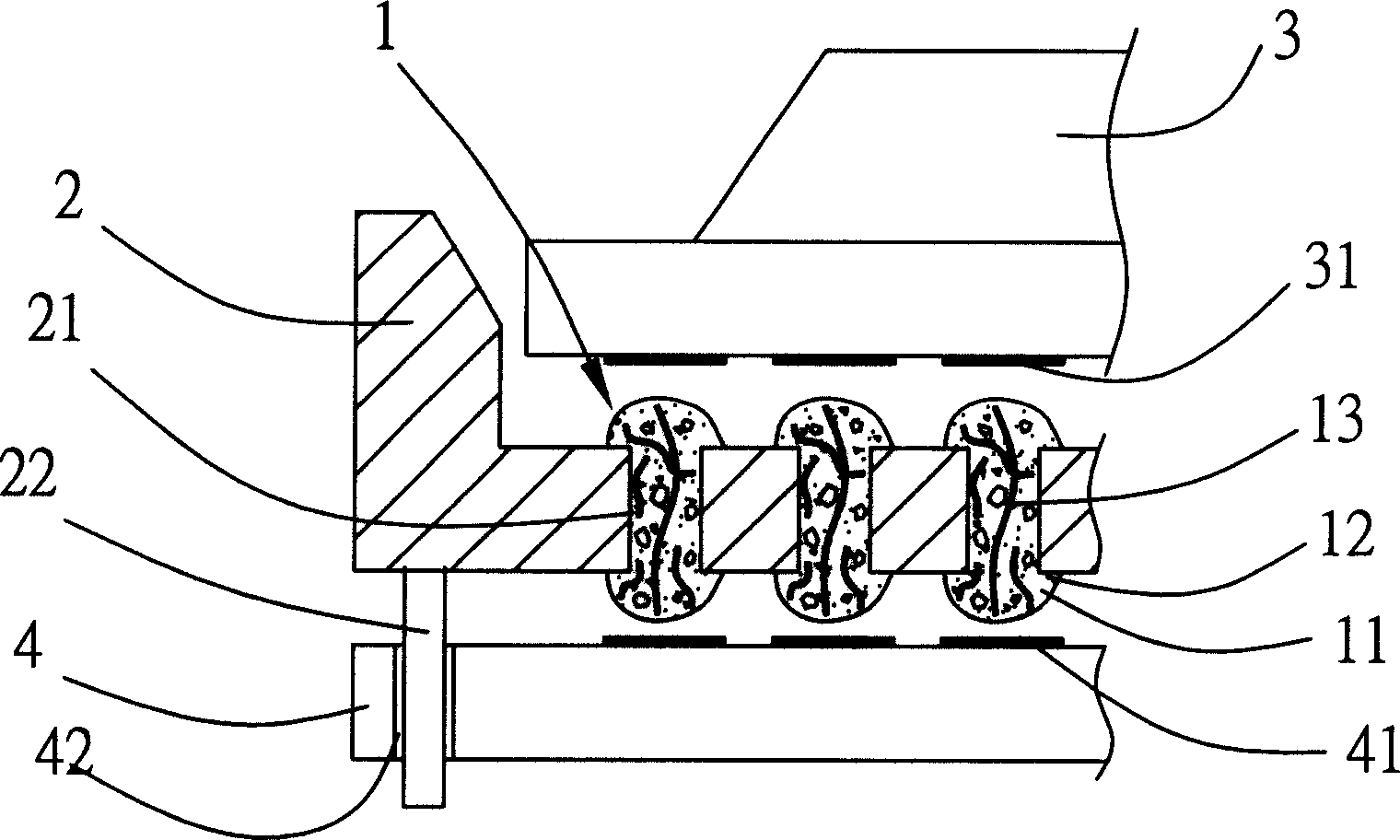

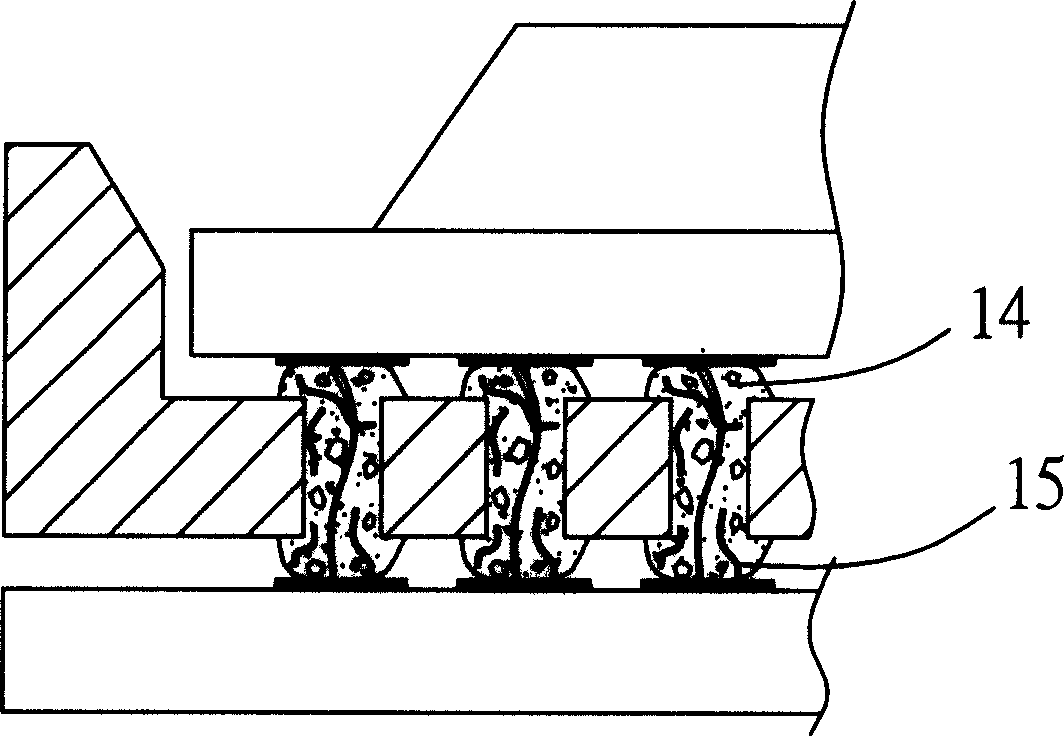

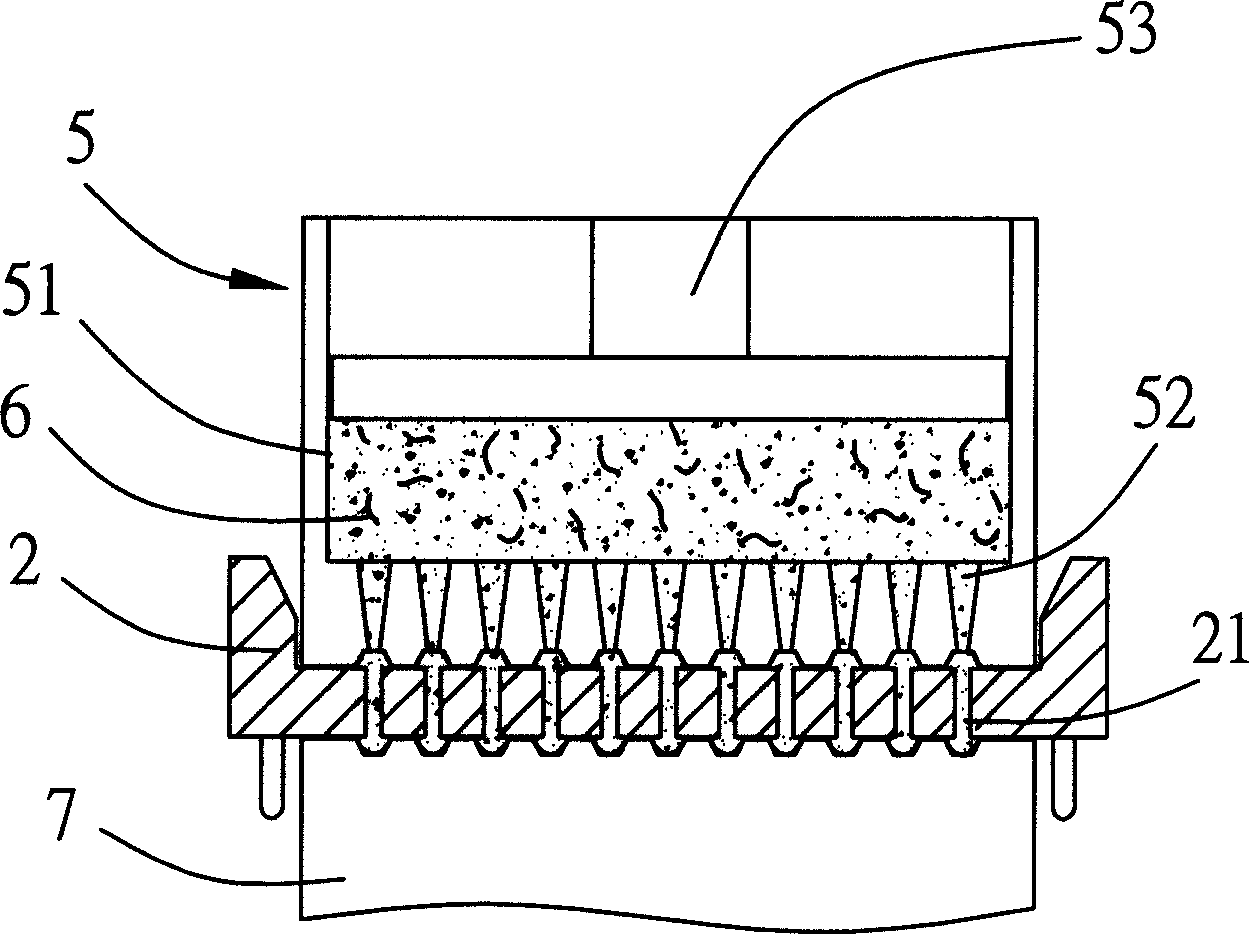

[0018] refer to figure 1 , figure 2 and image 3 , the electronic component of the present invention is an electrical connector, which includes an insulating body 2, a conductive rubber 1 planted in the insulating body 2, and is used to electrically connect the chip module 3 and the circuit board 4, wherein the chip module 3 and the circuit board 4 A first spacer 31 and a second spacer 41 are respectively provided.

[0019] The conductive rubber 1 includes an elastic matrix 11 filled with conductive powder 12 and a metal wire 13, wherein the metal wire 13 is accommodated in the elastic matrix 11, and the metal wire 13 is in the shape of a strip, placed roughly vertically, and approximately in line with the conductive rubber 1, so that when the volume of the conductive rubber 1 is constan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com