Elevator

A technology for elevators and cars, which is applied in the field of vibration-absorbing devices, and can solve problems such as increased structure and inability to accommodate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

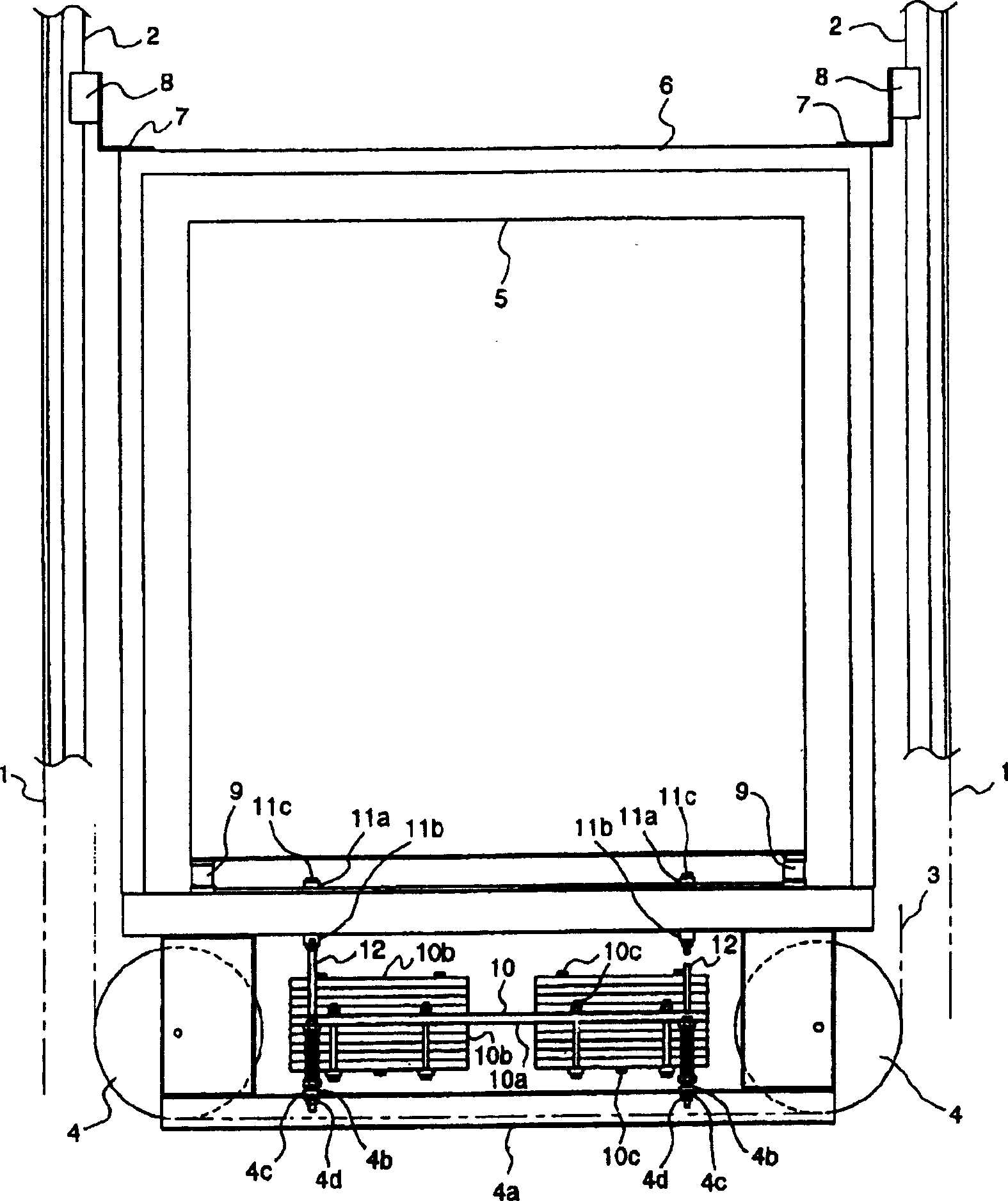

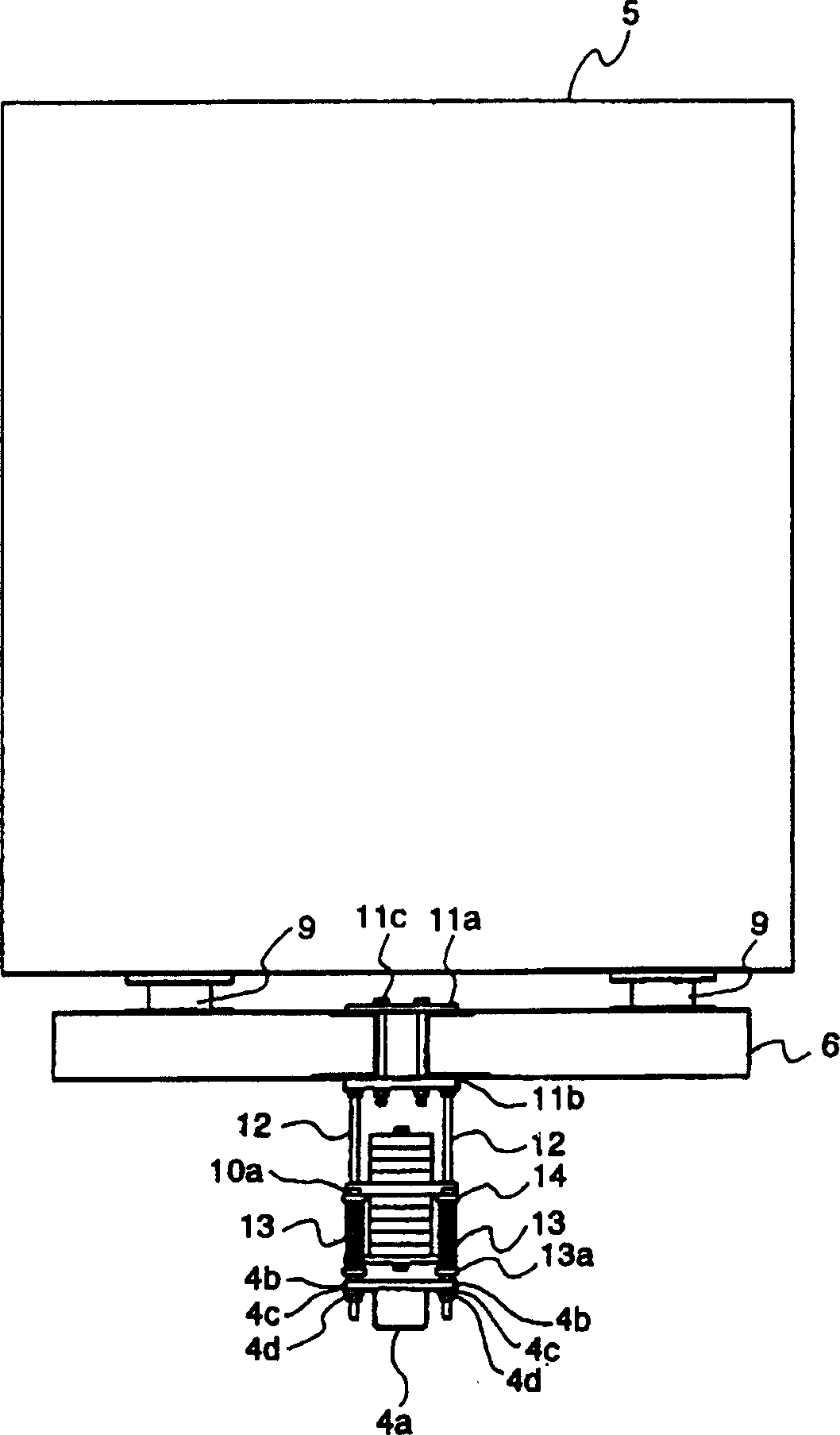

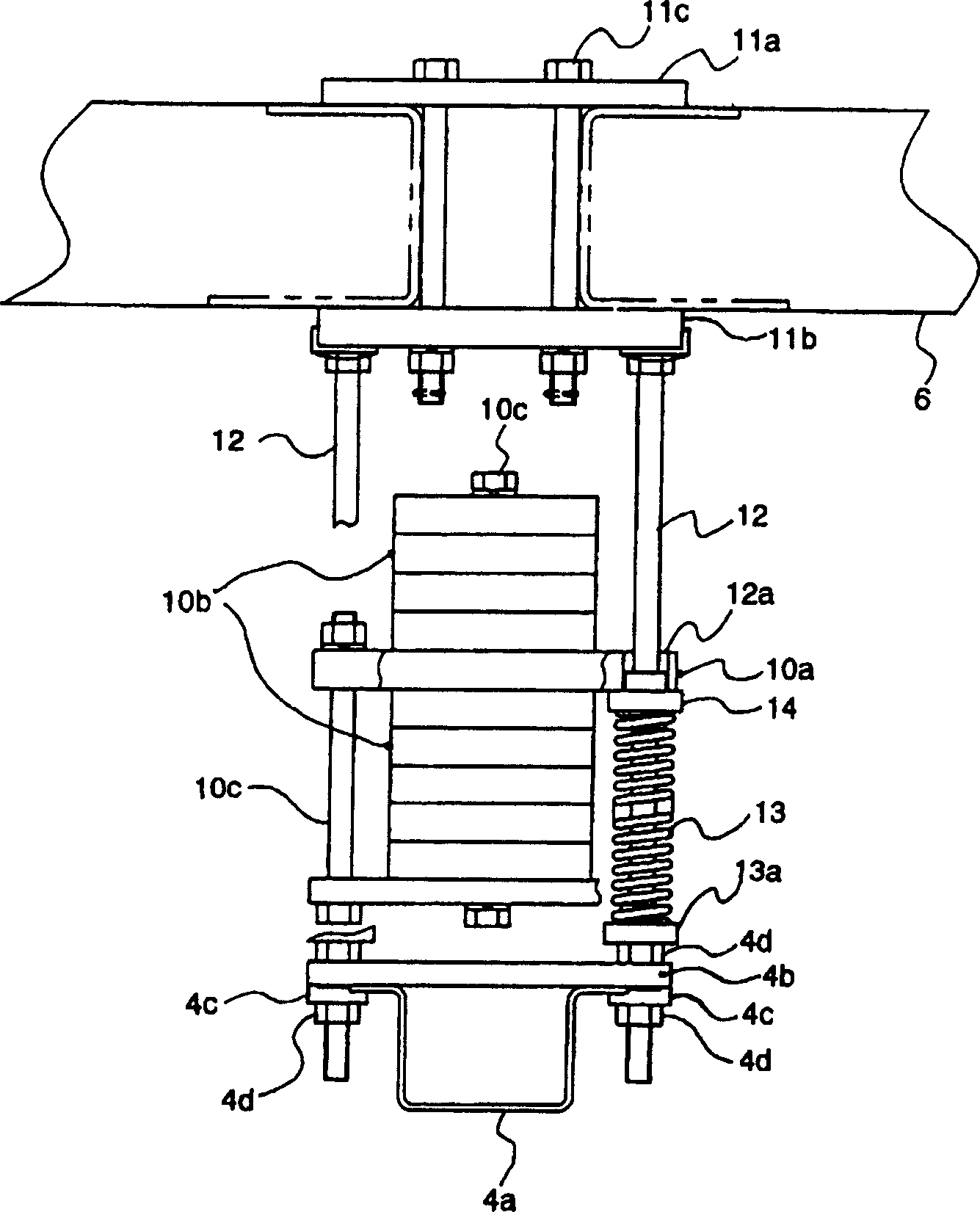

[0011] Embodiments of the present invention will be described below with reference to the drawings.

[0012] figure 1 It is a front view of a car frame part with an elevator vibration absorbing device according to one embodiment of the present invention. figure 2 yes figure 1 side view. image 3 yes figure 2 An enlarged view of the dynamic damper section of .

[0013] In the figure, 1 is the lifting channel of a high-rise building. Each guide rail 2 is vertically arranged on the two side walls of the lifting channel 1. Between the two guide rails 2, there is a lifter that passes through the lower pulley 4 of the car and is lifted freely. The cable 3 lifts the car frame 6 and the car 5 installed in the car frame 6 . In addition, each bracket 7 is attached to the upper and lower corners of the car frame body 6 (the lower part is not shown), and each guide device 8 is arranged in each bracket 7, which is arranged to be connected with each guide rail 2. The two sides and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com