Drum type washing machine

A drum-type washing machine, drum technology, applied to other washing machines, washing machines with containers, washing machine control devices, etc., can solve problems such as abnormal noise, abnormal vibration, longer detection time, etc., to prevent re-testing, The effect of preventing abnormal vibration and shortening the time of dehydration operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

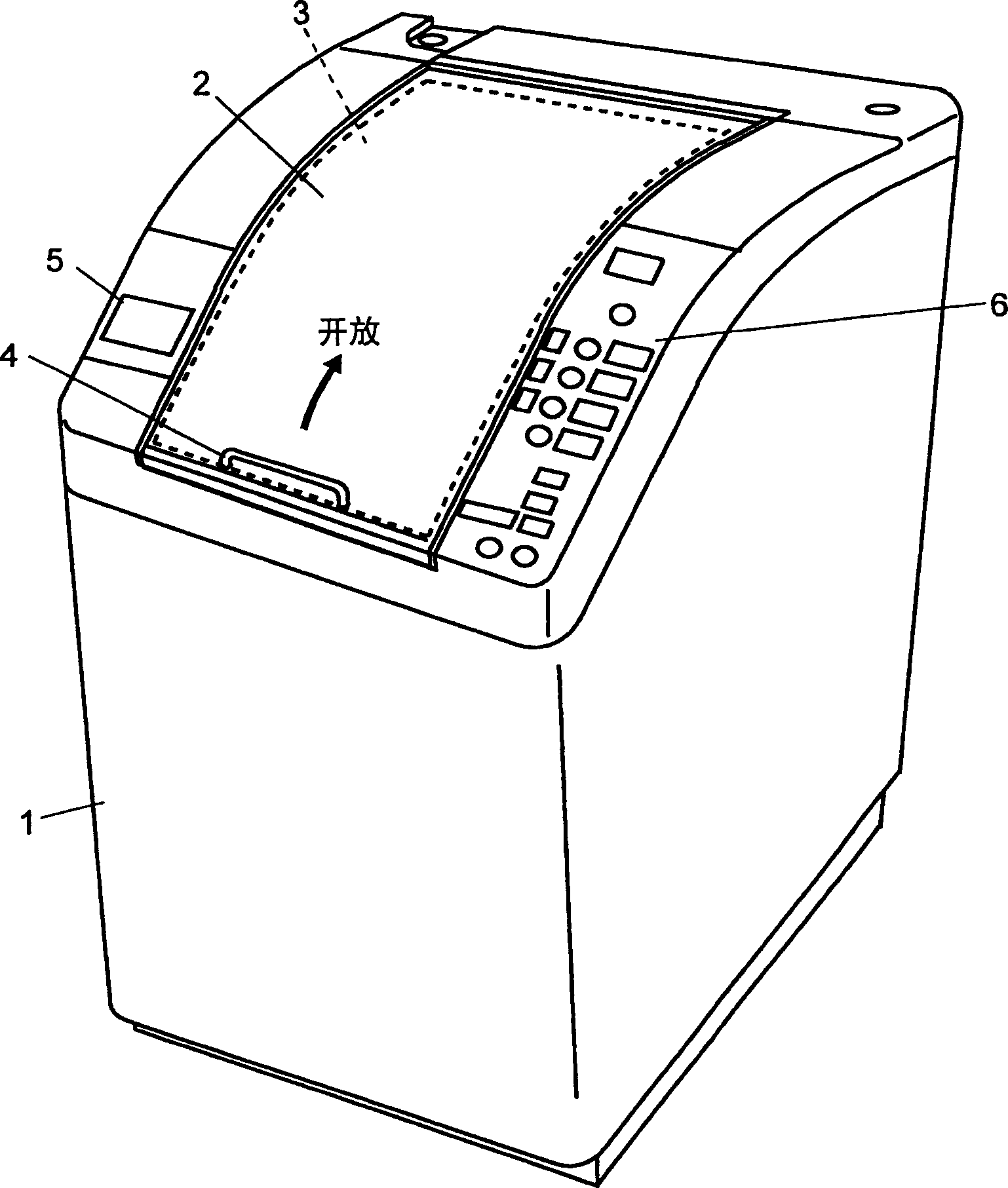

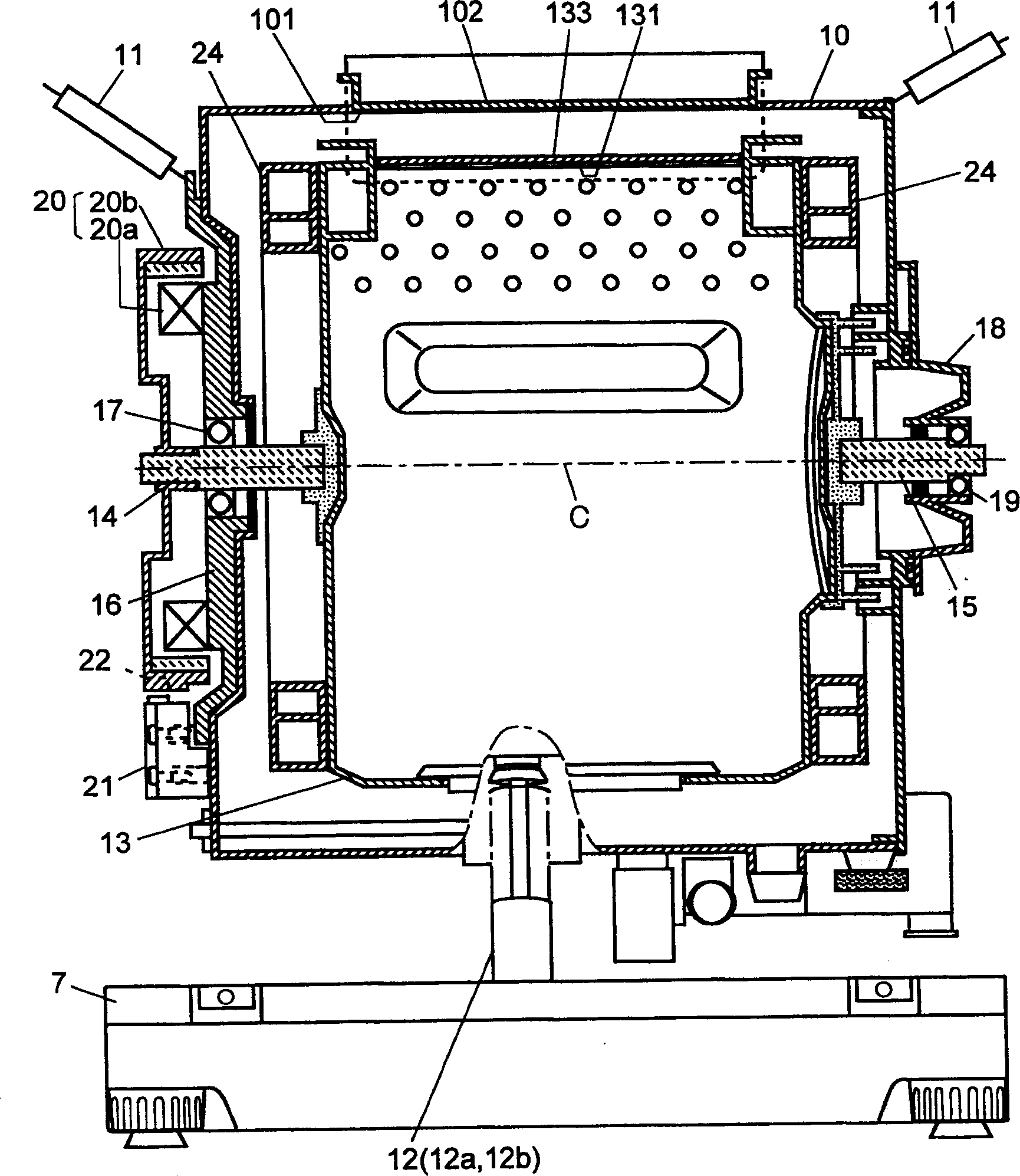

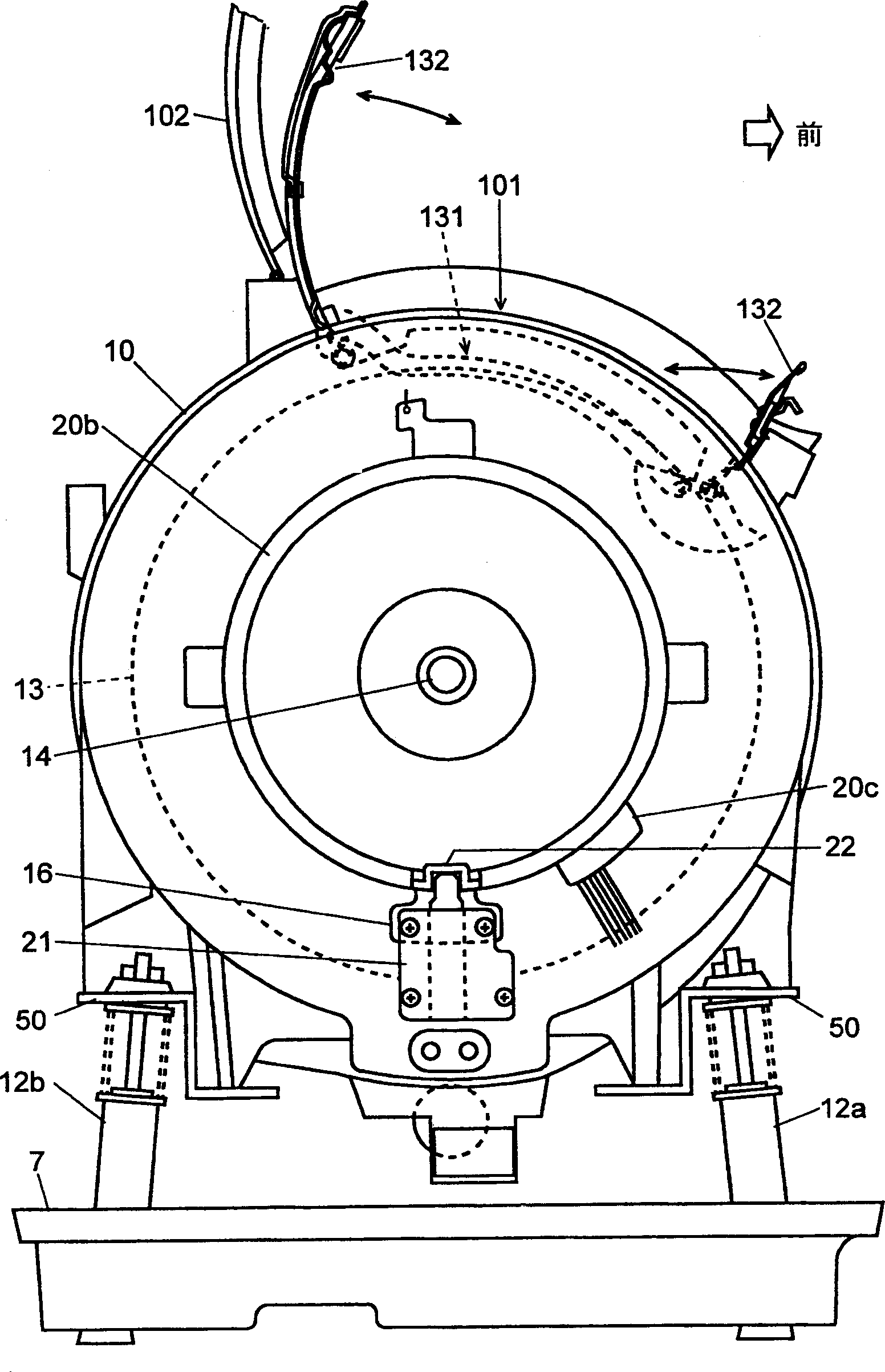

[0100] Below, refer to Figure 1 to Figure 13 A drum type washing machine according to an embodiment of the present invention will be described.

[0101] figure 1 It is a perspective view of the appearance of the front-loading-type washing machine of this embodiment. In this front-loading-type washing machine, the upper front portion of the outer case 1 is formed in a gently curved shape along the front and downward, and a laundry inlet 3 is formed in this portion. The washings are put into the opening 3, which can be opened and closed freely by the upper cover 2 which can slide and move in the front and rear directions, hold the handle 4 which is located at the front edge of the upper cover 2 and move as shown figure 1 Push back as indicated by the middle arrow to open the laundry inlet 3. At this time, the upper cover 2 is housed on the rear side of the outer case 1 . A detergent container 5 that can be freely drawn out is provided on the front left side of the upper cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com