Chain driven slide automatic air valve

A chain drive and damper technology, which is used in mine/tunnel ventilation, mining equipment, earth-moving drilling, etc., can solve problems such as burnout, inaccurate transmission force and transmission position, and difficulty in accurately controlling the damper load.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

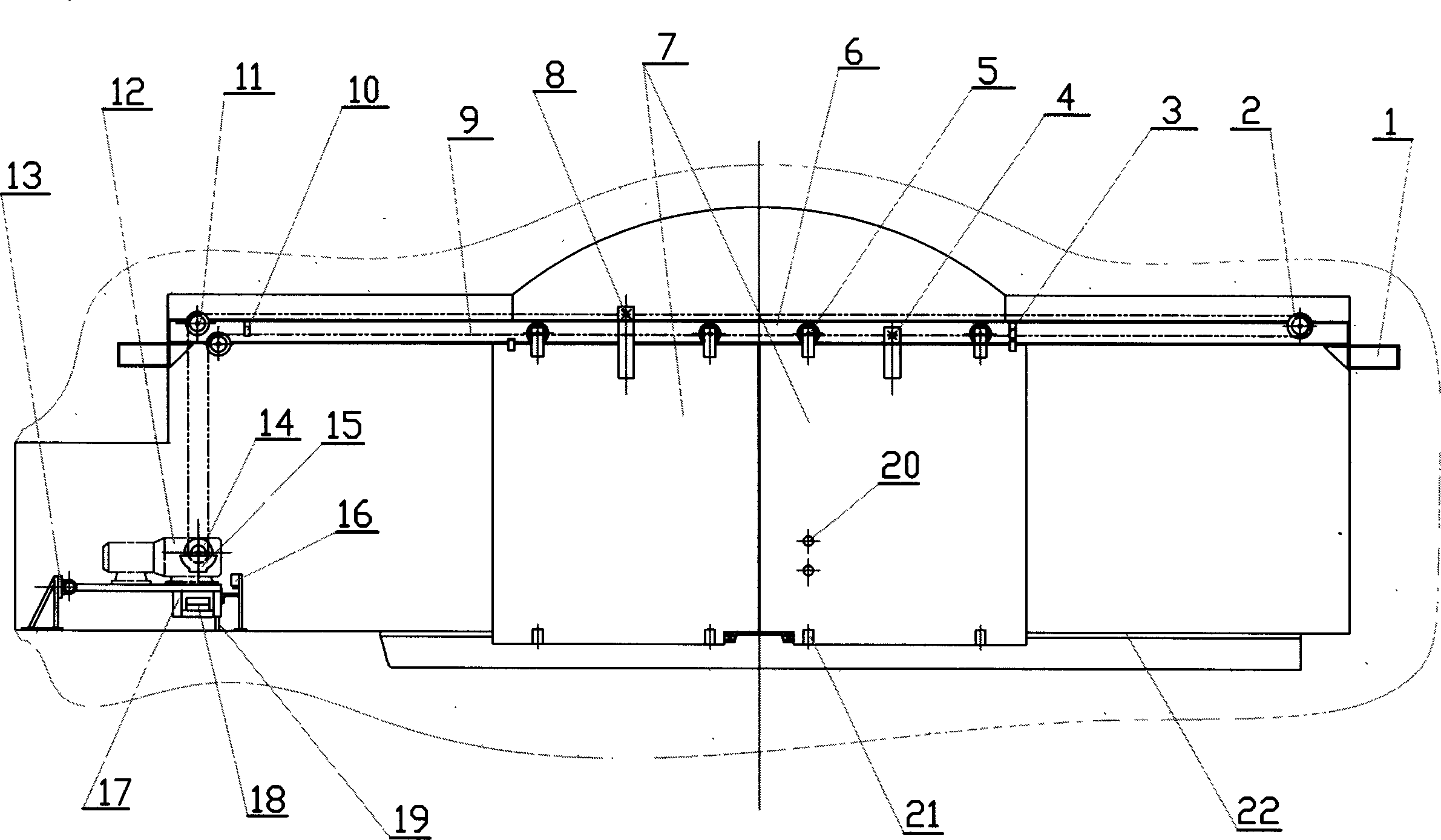

[0005] Excavate air door chambers on both sides of the roadway where the air door is installed, and guide rail supports (1) are pre-buried on the top of both ends of the chamber, and I-beam guide rails (6) are installed on the supports, and two push-pull air doors (7) It is hoisted on the I-shaped steel guide rail by means of rollers (5), and a trench is arranged on the floor at the lower end of the damper, and lower rails (22) are buried on both sides of the trench, and the two air doors are stuck between the two lower rails. Vertical roller (21) is equipped with at damper lower end, and damper slides between two slide rails under the guide action of vertical roller. The right end of guide rail (6) is installed right to change sprocket wheel (2), is installed with left upper change sprocket wheel (11) and left lower change sprocket wheel at the left end of guide track. Install the swing machine base (17) on the floor of the chamber on the left side, the left end of the machin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com