Automobile servicing process, and automobile servicing equipment

A technology for vehicle maintenance and maintenance equipment, which is applied in vehicle maintenance/repair, workshop equipment, vehicle maintenance, etc. It can solve the problems of high pit construction costs, increased maintenance costs, and low operating efficiency, and achieves cheap equipment costs and improved Efficiency, achieve the effect of maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Hereinafter, a preferred embodiment of the present invention will be described with reference to the drawings.

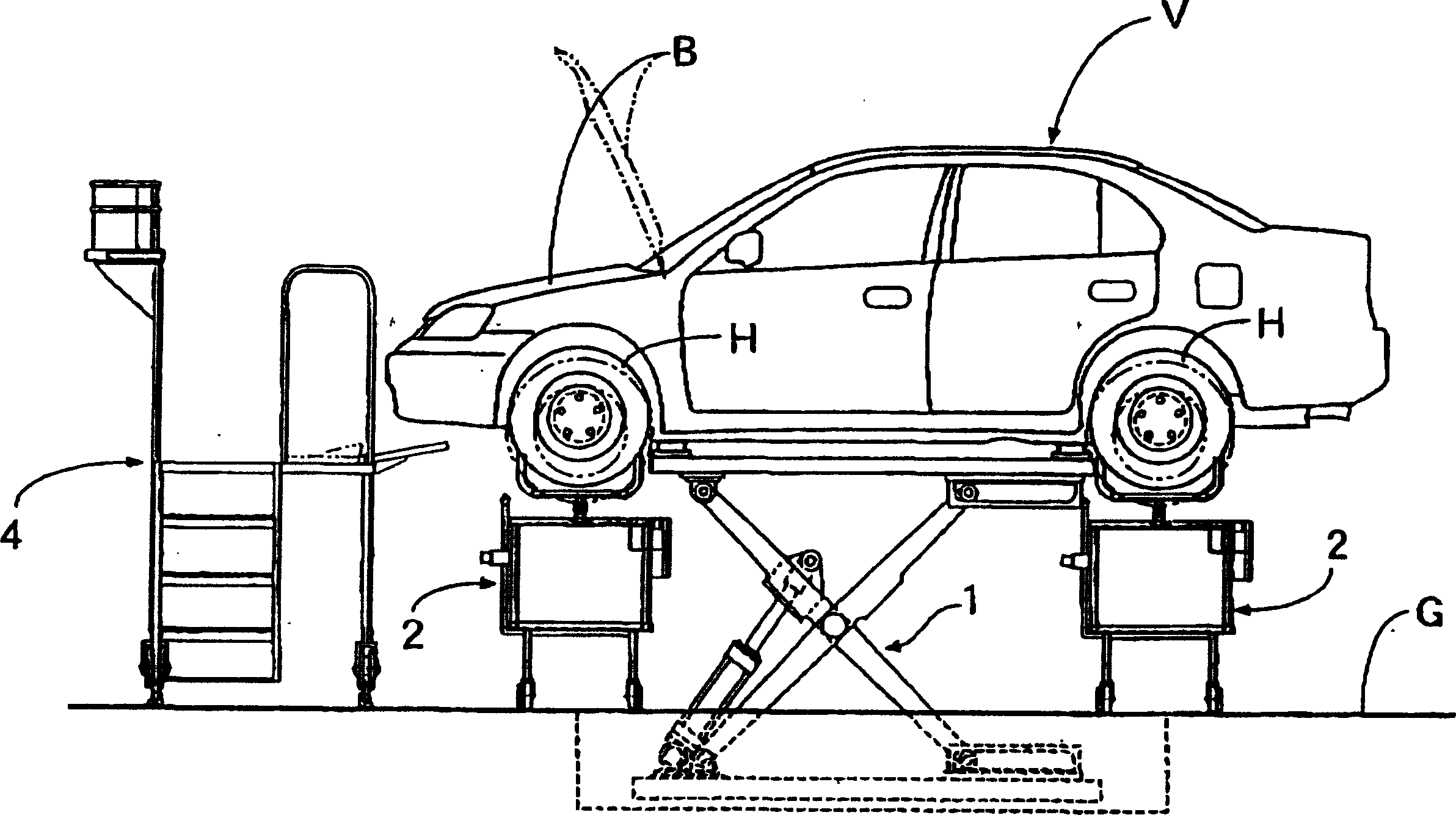

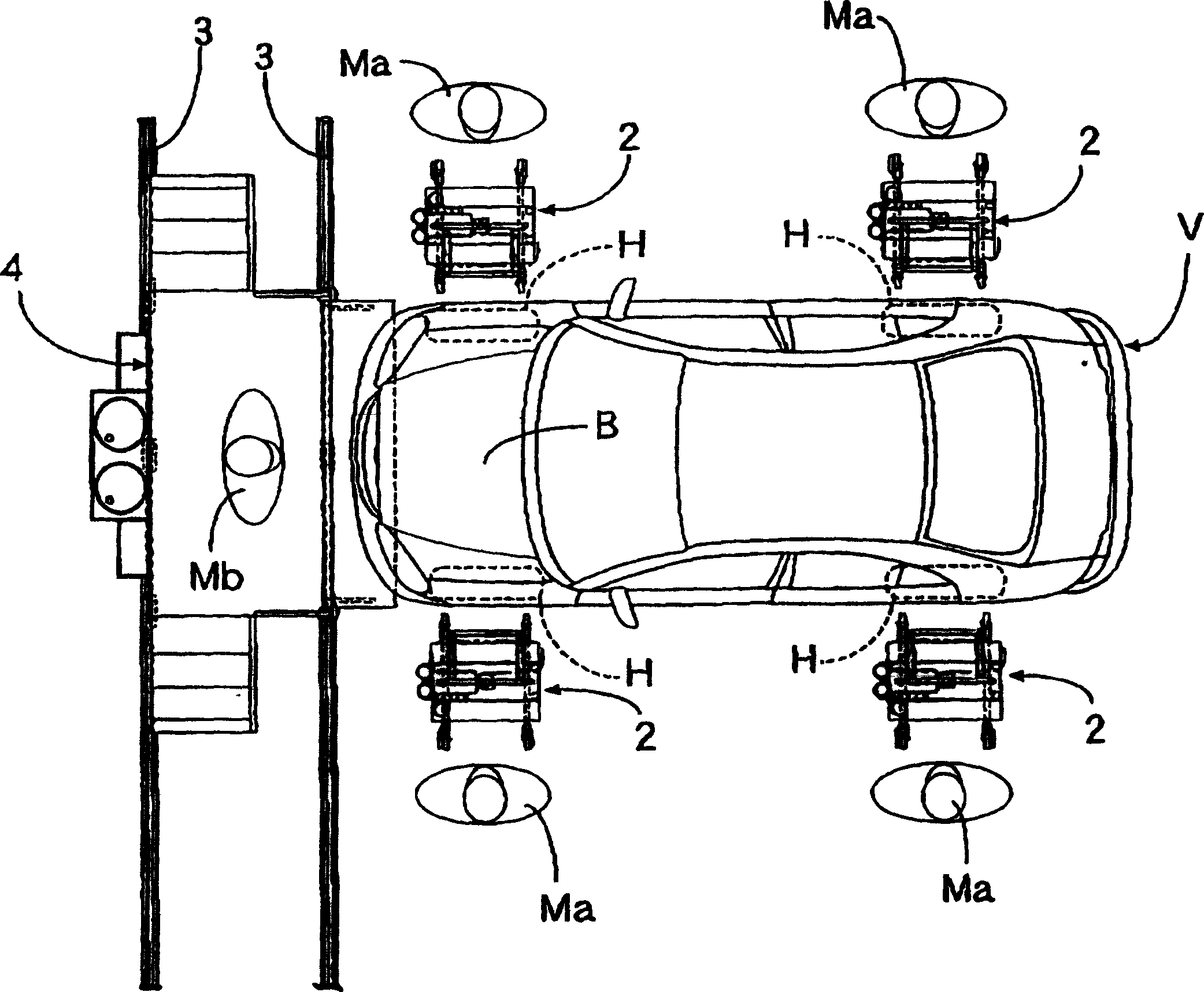

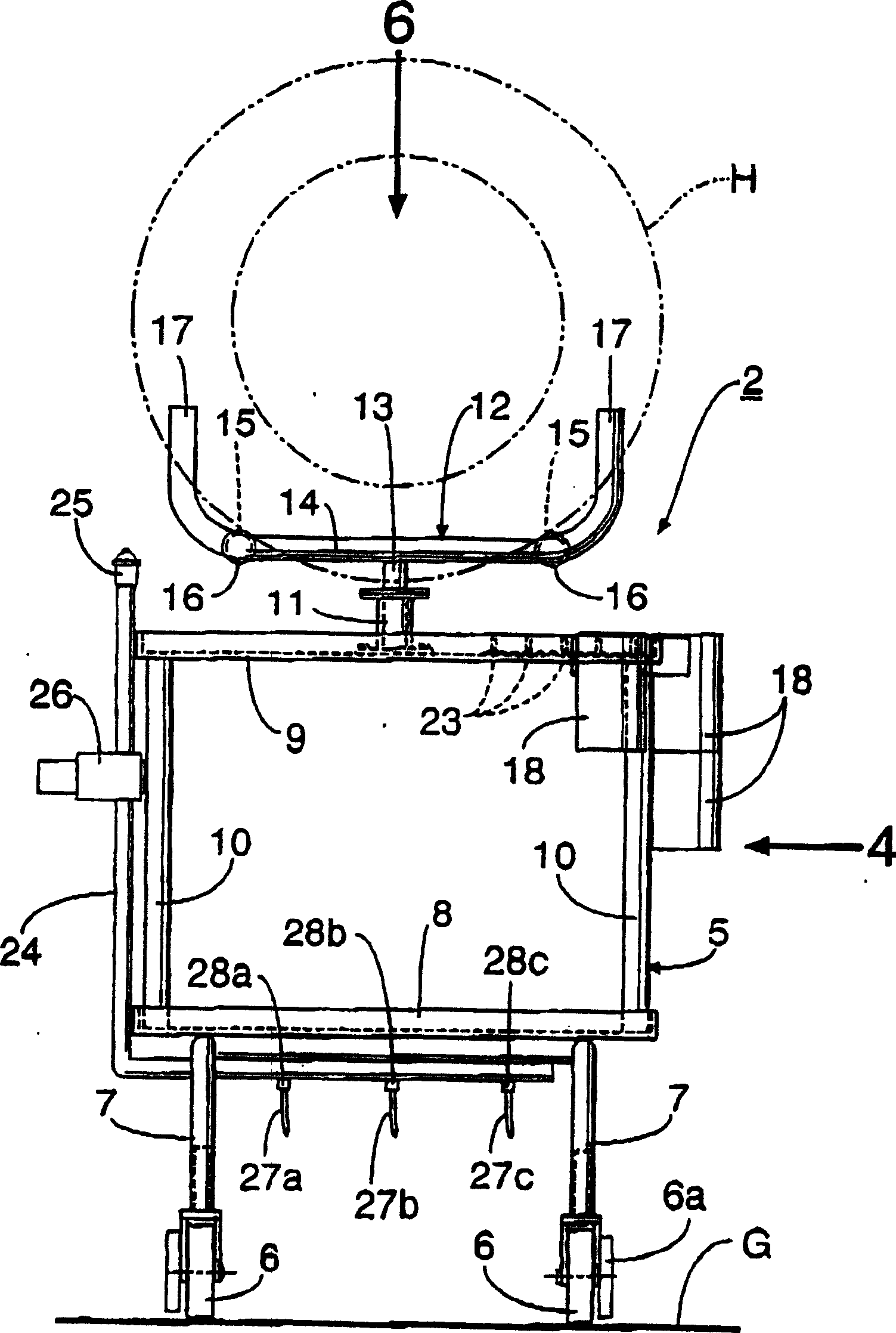

[0034] exist figure 1 with figure 2 Among them, the maintenance equipment of the automobile repair shop is composed of the following parts: an elevator 1 set on the ground G for lifting and lowering the automobile V that needs maintenance; four wheels H, H... corresponding to the automobile V that is raised and lowered by the elevator 1 are arranged on the 4 traveling part maintenance trolleys 2 around the elevator 1; corresponding to the front end of the car V lifted by the elevator 1, a pair of front and rear guide rails 3, 3 that are arranged on the ground G and extend along the width direction of the car V; An engine part maintenance work trolley 4 is movably provided on these guide rails 3, 3, and can be arranged facing the front of the engine compartment of the lifted vehicle V. As shown in FIG.

[0035] in addition, figure 2 The symbol Ma in the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com