Hyperelastic marmem composite friction dumper

A technology of friction damper and memory alloy, which is applied in the direction of spring/shock absorber, spring, shock absorber, etc., can solve the problems of fluid damper leakage, degradation of mechanical properties, poor fatigue resistance, etc. Restore the effect of large deformation and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

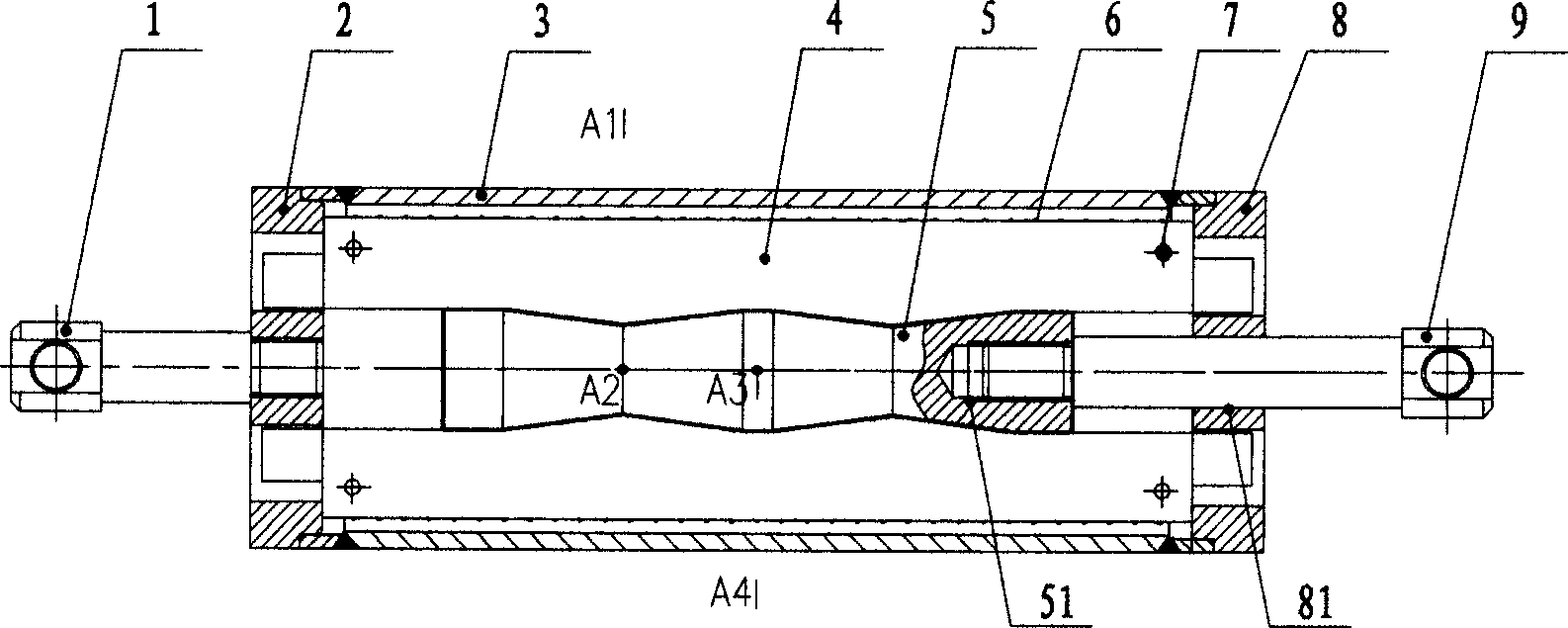

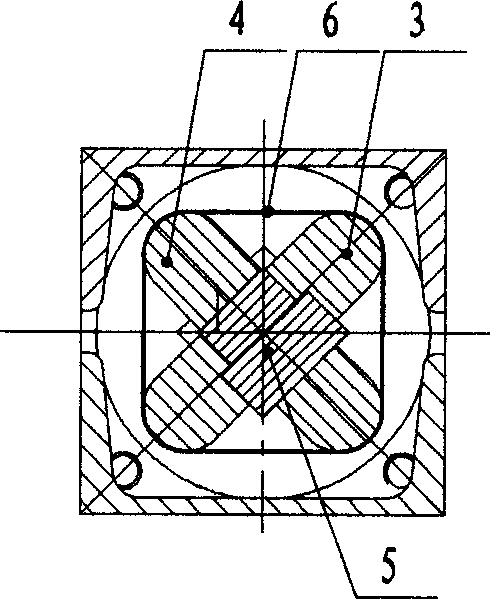

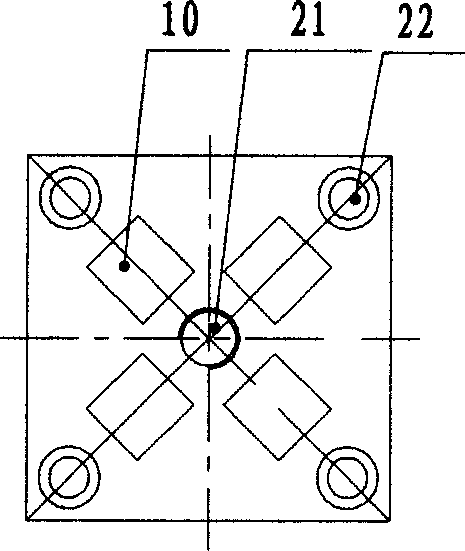

[0017] The superelastic shape memory alloy composite friction damper of the present invention comprises a left tie rod 1, a front cover 2, an outer cylinder 3, an outer slide bar 4, an inner slide bar 5, a superelastic shape memory alloy wire 6, a rear cover 8, and a right pull rod 9 Wherein, on the outside of the inner slide bar 5, more than two outer slide bars 4 are arranged symmetrically to the axis of the inner slide bar 5, and the outside of the inner slide bar 5 and the inner side of the outer slide bar 4 are wavy along the axial direction , and the inner sliding bar 5 and the outer sliding bar 4 are meshed with each other by the wavy contact surface; outside the whole body composed of the inner sliding bar 5 and more than two outer sliding bars 4, a superelastic shape memory alloy wire is used along its outer circumference 6 Wrap and tie tightly, and put the bundled whole into the outer cylinder 3; the two ends of the outer cylinder 3 are respectively provided with a fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com