Soft switch power factor correcting circuit

A power factor correction, soft switching technology, applied in the output power conversion device, the conversion of DC power input to DC power output, electrical components and other directions, can solve the problems of low efficiency and large on-state loss of the whole machine Improved efficiency and reduced on-state loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

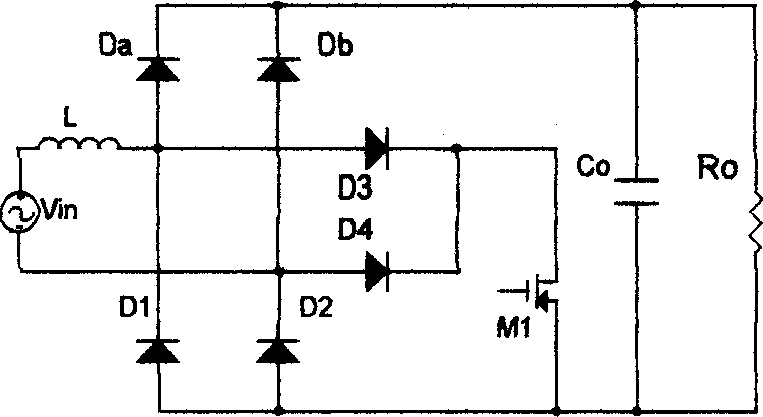

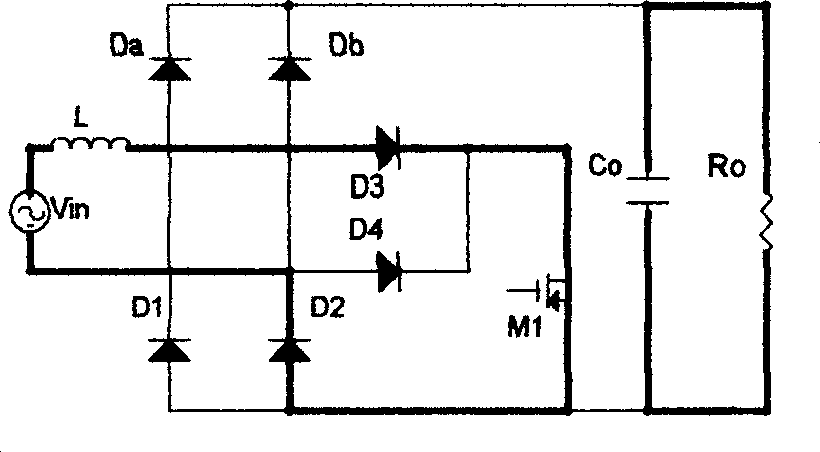

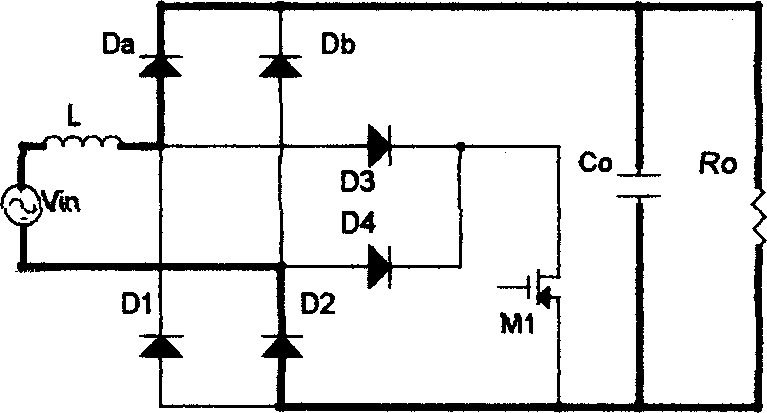

[0018] The inventive circuit such as image 3 As shown, it includes a diode bridge rectifier circuit and a boost converter circuit, and the bridge rectifier circuit includes a first diode D1, a second diode D2, a third diode D3, a fourth diode D4 four rectifier diodes, the common cathode of the bridge rectifier circuit is connected to the drain of the main power switch M1, and its common anode is connected to the source of the main power switch M1, and the input AC power V in One end of the series branch composed of the filter inductance L is connected to the anode of the eighth diode Da between the first diode D1 and the third diode D3, and the other end is connected to the anode of the ninth diode Db. Between the second diode D2 and the fourth diode D4, the cathodes of the eighth diode Da and the ninth diode Db are connected to the output filter capacitor C o One end, the output filter capacitor C o The other end is connected to the common anode of the bridge rectifier cir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com