Differential amplifier with temp compensation function

A differential amplifier, temperature compensation technology, used in differential amplifiers, amplifiers, amplifiers with semiconductor devices/discharge tubes, etc., can solve problems such as gain and distortion changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

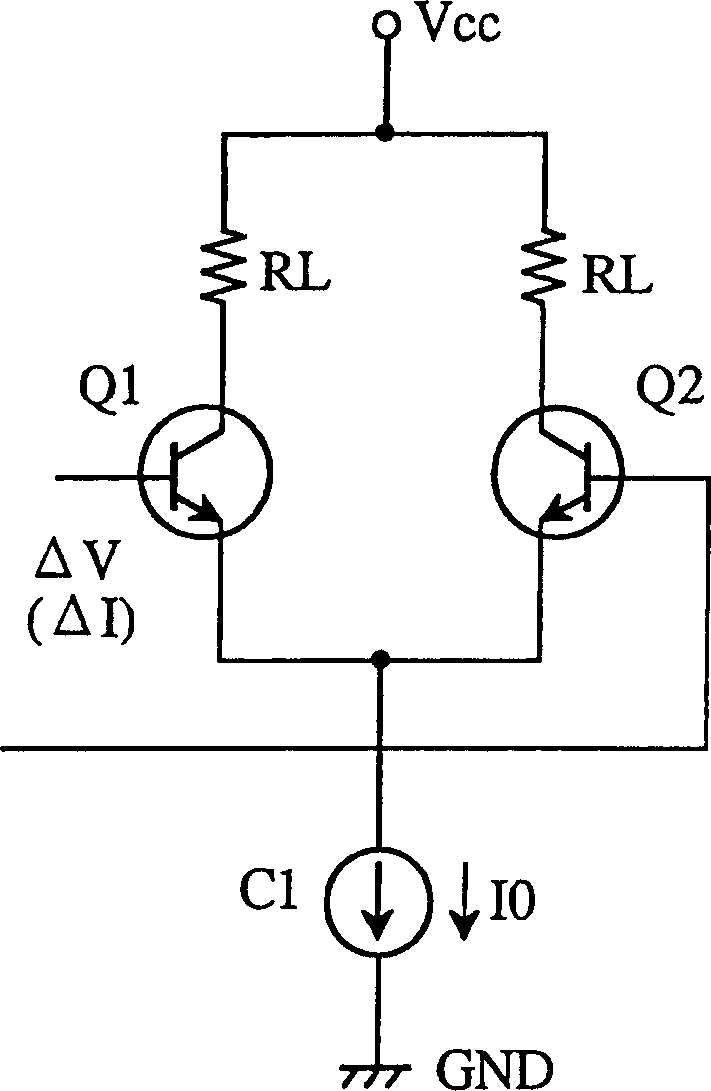

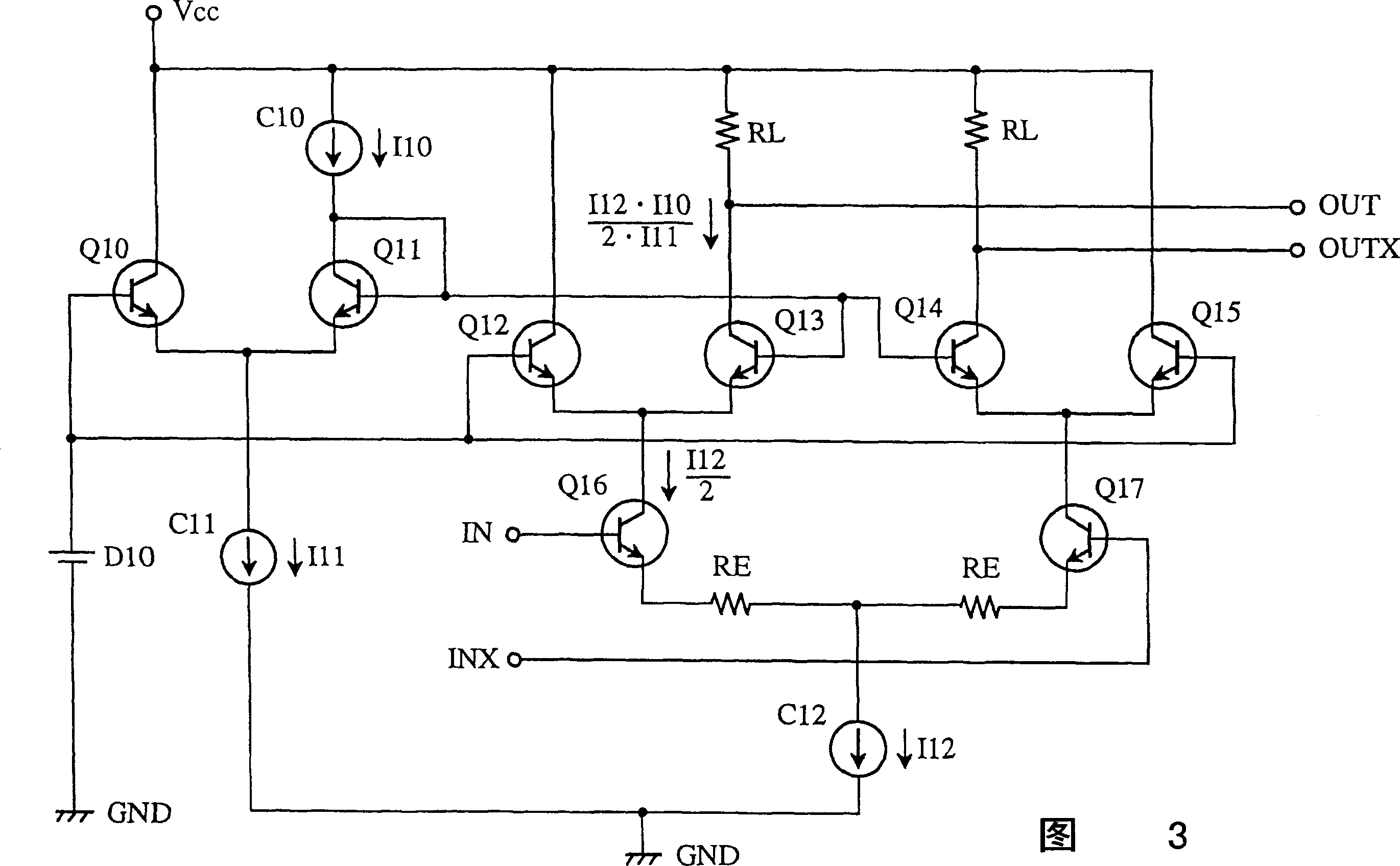

[0032] Hereinafter, in order to describe the present invention in more detail, the best mode for carrying out the present invention will be described with reference to the accompanying drawings.

[0033] Embodiment 1

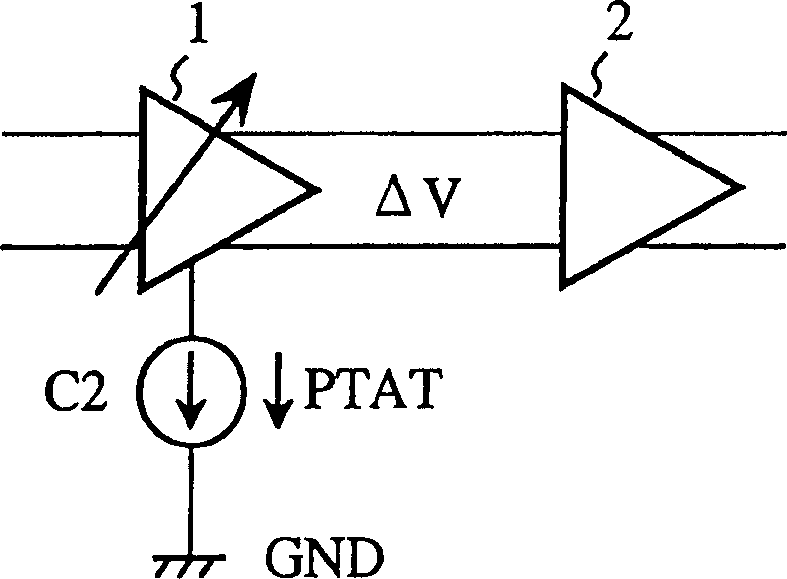

[0034] figure 2 It is a diagram showing the configuration of a differential amplifier with a temperature compensation function according to Embodiment 1 of the present invention. In the figure, 1 is a differential amplifier (the first differential amplifier) with a feedback resistor and a characteristic that the gain is proportional to the absolute temperature, and C2 is a current proportional to the temperature PTAT (Proportionality ToAbsolute Temperature, which is proportional to the absolute temperature) ) constant current source. 2 is a differential amplifier (second differential amplifier) connected to the subsequent stage of the differential amplifier 1, having no feedback resistor and having a characteristic that the gain is inversely proportional ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com