Structure for fixing filter in washing machine

A fixed structure and filter technology, which is applied to other washing machines, washing devices, textiles and papermaking, etc., can solve the problems of filter deformation and filter inability to form, and achieve the effect of increasing strength and preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

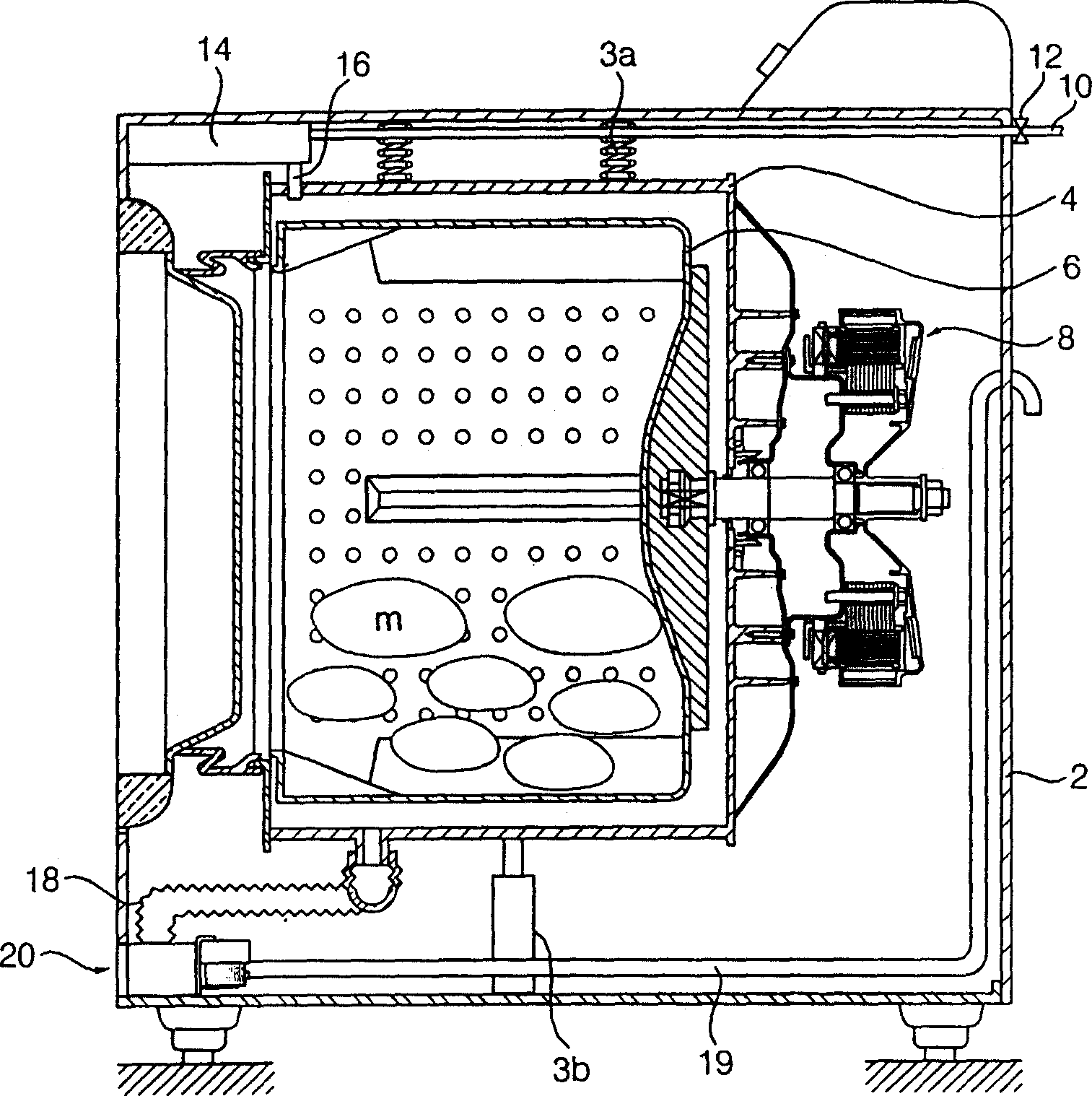

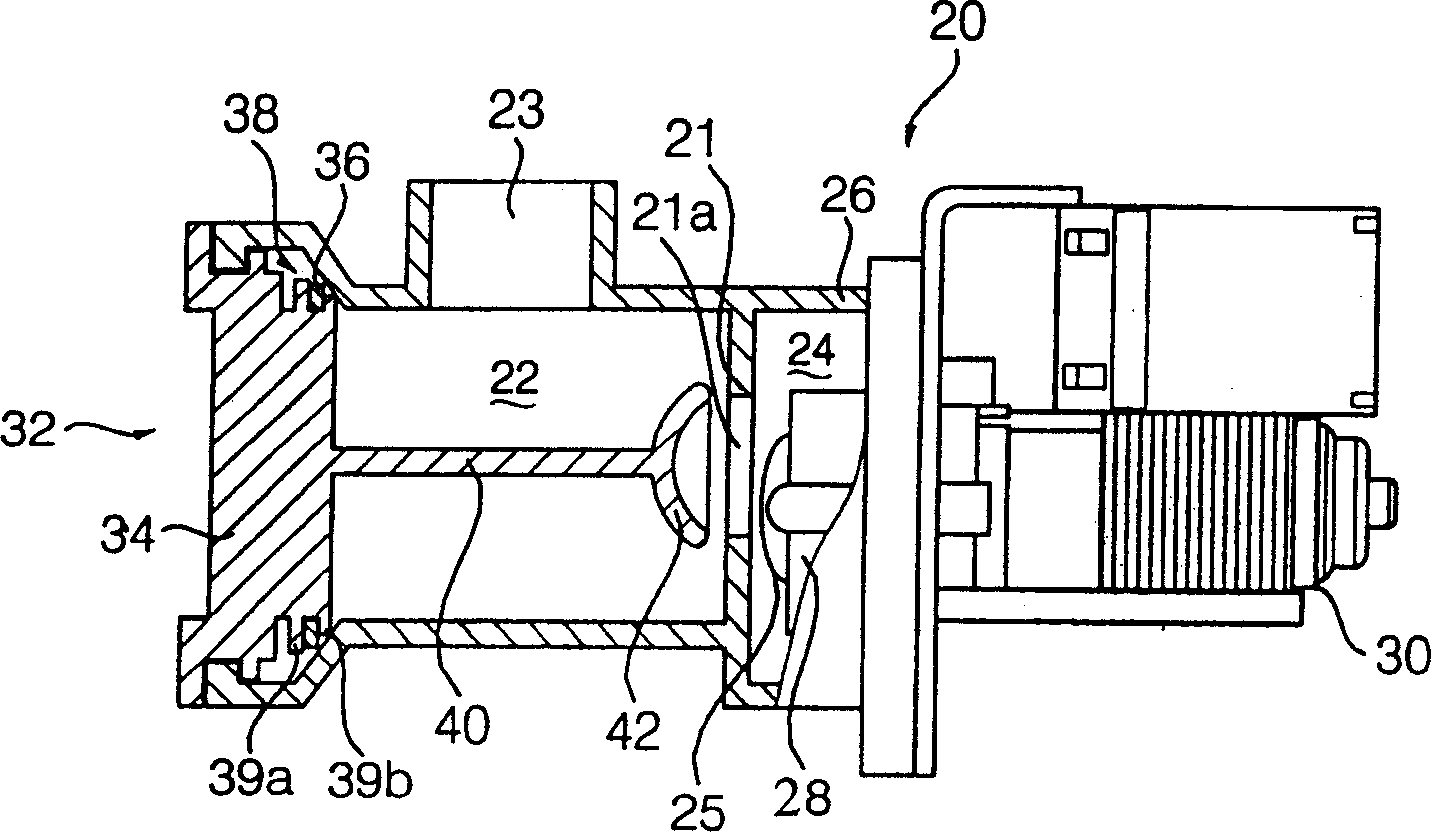

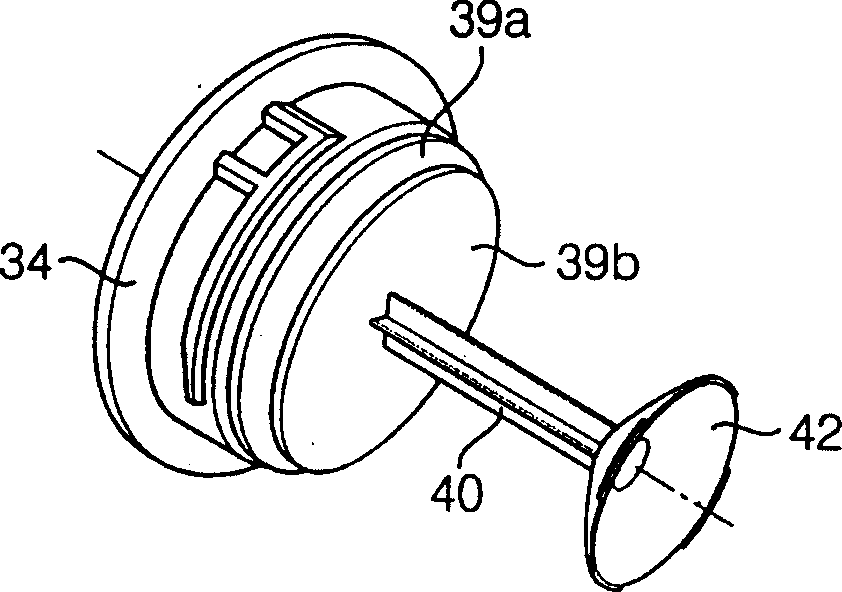

[0032] In order to further understand the content, characteristics and effects of the present invention, the following examples are given, and detailed descriptions are as follows in conjunction with the accompanying drawings:

[0033] Such as Figure 4 and Figure 5 Shown, the washing machine water pump (50) among the present invention is by forming the suction tank (52) of filter chamber (54) and suction chamber (56), in suction chamber (56) adorns impeller (62), is fixed on the suction tank ( 52) The pumping motor (60) on the back side is formed. On the front end side of the suction box (52), a filter (70) is detachably installed in the filter chamber (54).

[0034] In the pumping tank (52), the interior is divided into a filter chamber (54) and a pumping chamber (56) by a partition (53), and the partition (53) is provided with an opening hole communicating with the filter chamber (54) and the pumping chamber (56) (53a).

[0035] In the suction tank (52), the water supp...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap