Apparatus for forming a yarn reserve winding and a cross wound bobbin on a bobbin tube

A cross-winding bobbin and cross-winding technology, applied in the field of winding devices, can solve problems such as no description

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

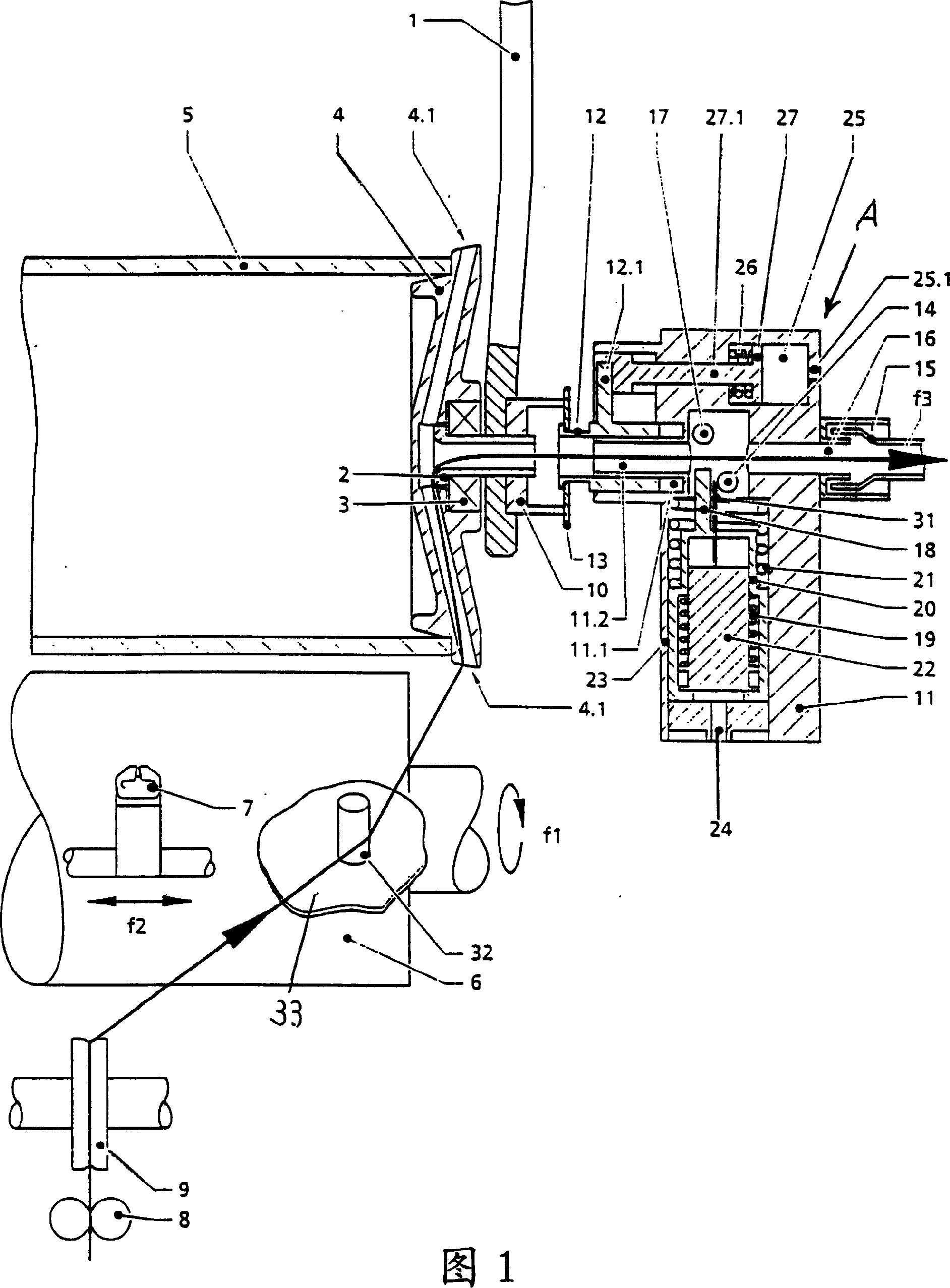

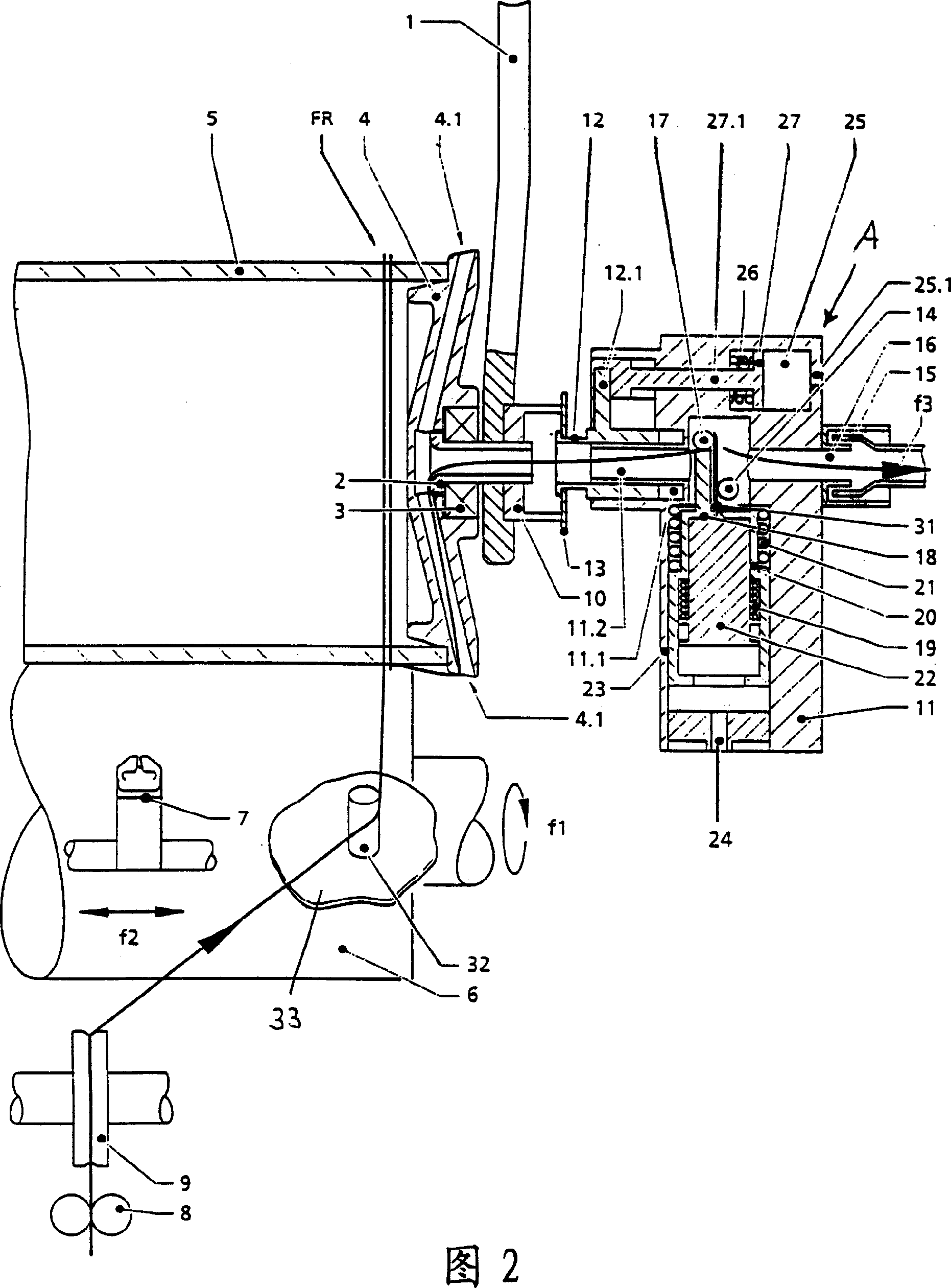

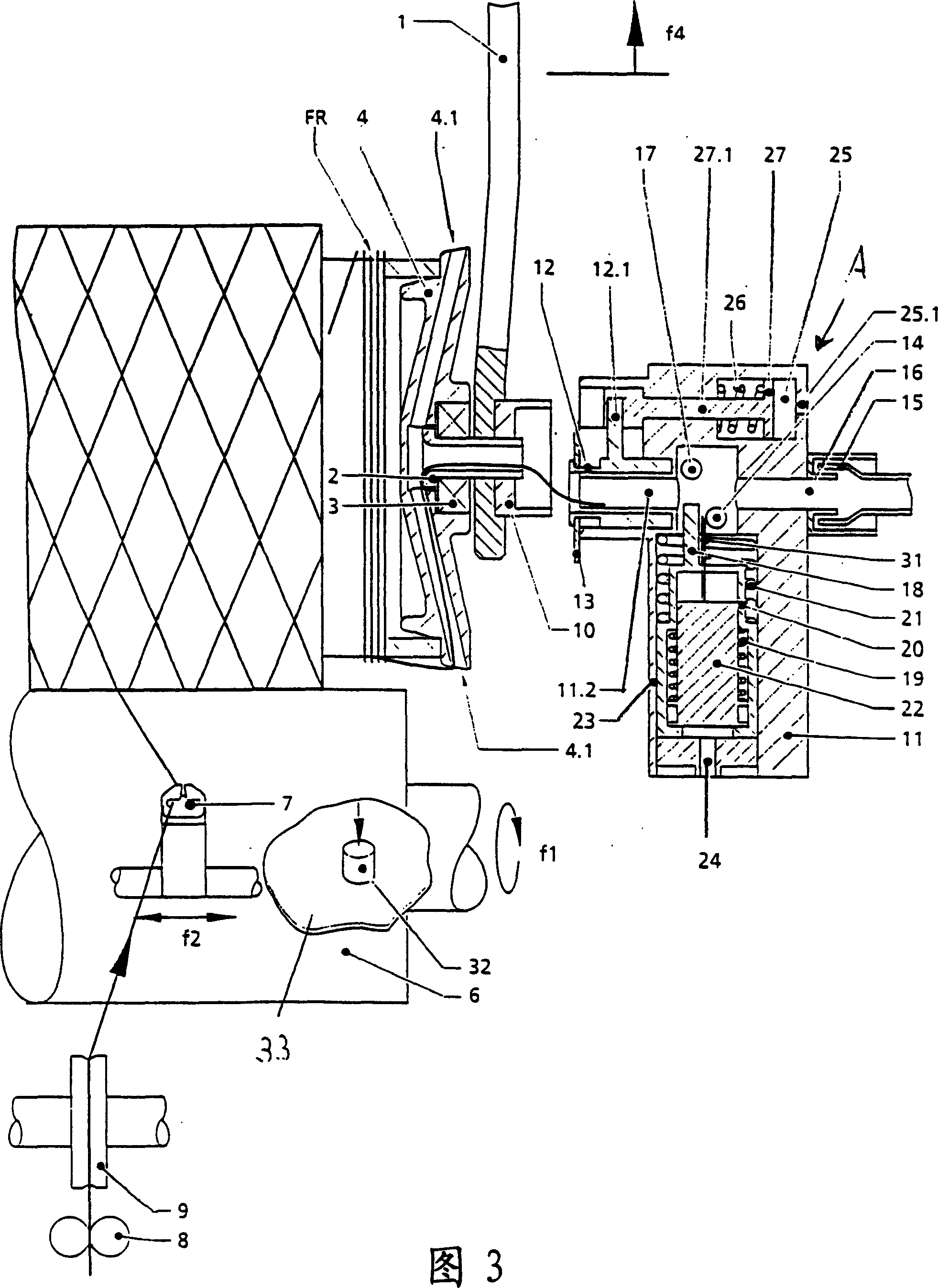

[0014] 1-3 only show a creel arm 1 of a creel generally known, for example, from DE2711024C2, on which a hollow shaft 2 is mounted. A centering disk 4 is supported on the hollow shaft 2 by means of a bearing 3 and has at least one suction channel 4.1 extending radially inwards from its outer peripheral surface. Each suction channel opens into the hollow shaft 2 . Mounted on the centering disk 4 is a bobbin 5 which can be driven by means of a friction drive roller 6 which can be driven in the direction of the arrow f1. The friction drive roller 6 is provided with a traverse guide 7 capable of moving back and forth in the direction of the double arrow f2. FIG. 1 also shows a feed roll 8 and a conventional overfeed roll 9 .

[0015] The hollow shaft 2 opens into a cylindrical housing 10 which is substantially open on its outer end face.

[0016] A suction head A is arranged next to the creel arm 1 . The suction head A has a housing 11 with an annular chamber 11.1 open towards...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com