Trick plate spacing changer for double raschel machines

A technology of warp knitting machine and double needle bed, which is applied in warp knitting, flat warp knitting machine, knitting, etc., and can solve problems such as knitting obstacles, deviations, and complicated operations for changing the interval of needle groove plates.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Next, an embodiment of the needle groove plate interval changing device in the double-needle bed Raschel warp knitting machine of the present invention will be described based on the embodiments of the drawings.

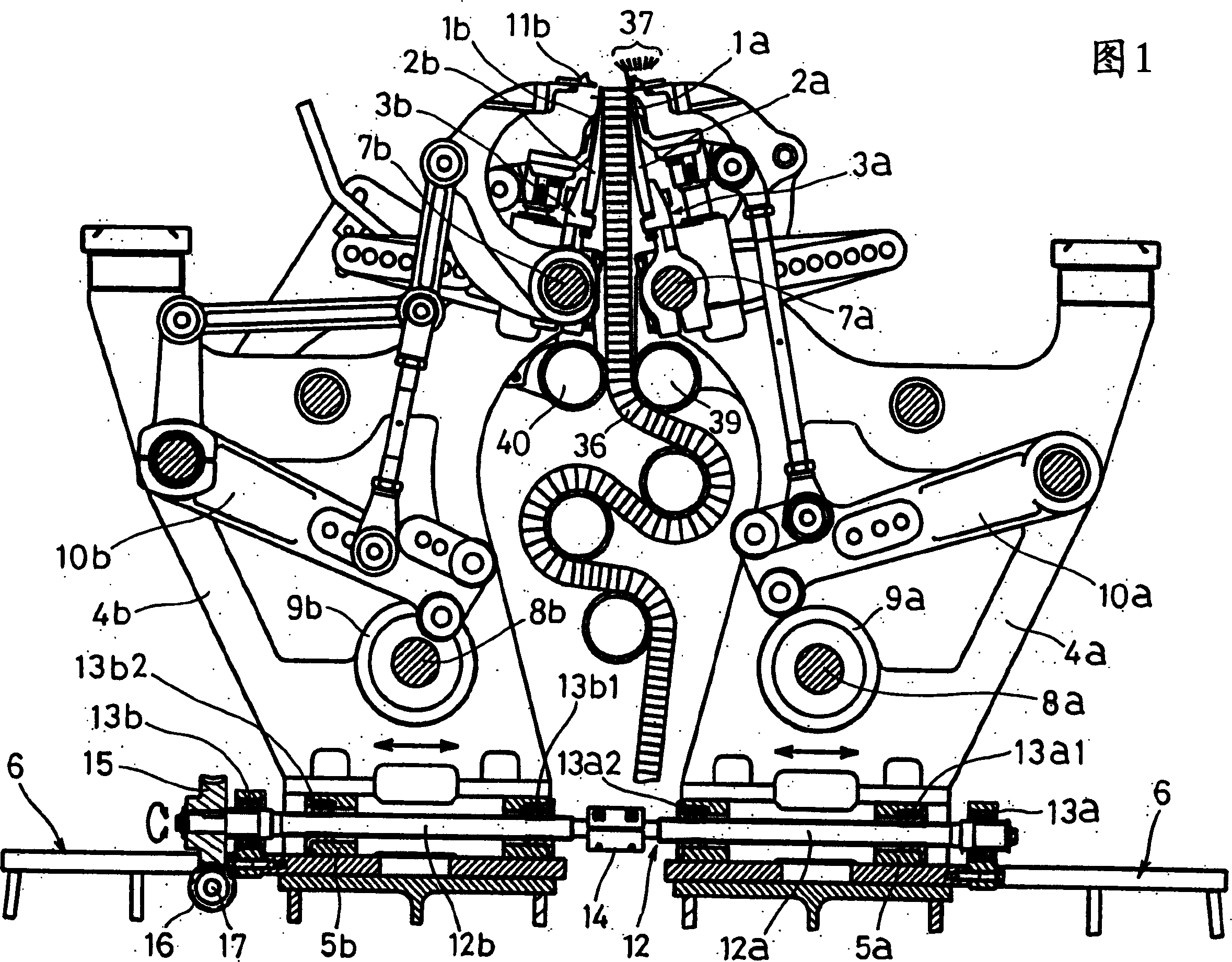

[0019] Fig. 1 is a cross-sectional view cut in a direction perpendicular to the machine width direction of a double-bar raschel warp knitting machine including a needle groove plate interval changing device according to the present invention.

[0020] In the same figure, 1a is a front knitting needle, 2a is a front needle groove plate, and this needle groove plate 2a is attached to the holder 3a. In addition, 1b is a rear knitting needle, 2b is a rear needle groove plate, and this needle groove plate 2b is attached to the holder 3b. A plurality of knitting needles 1a, 1b before and after are juxtaposed in respective knitting machine width direction (vertical direction with respect to the paper surface of Fig. extend across the width of the machine.

[0021] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com