Back light module assembly

A backlight module and light guide plate technology, which is applied in optics, nonlinear optics, instruments, etc., can solve problems such as poor light uniformity, and achieve the effect of improving light uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

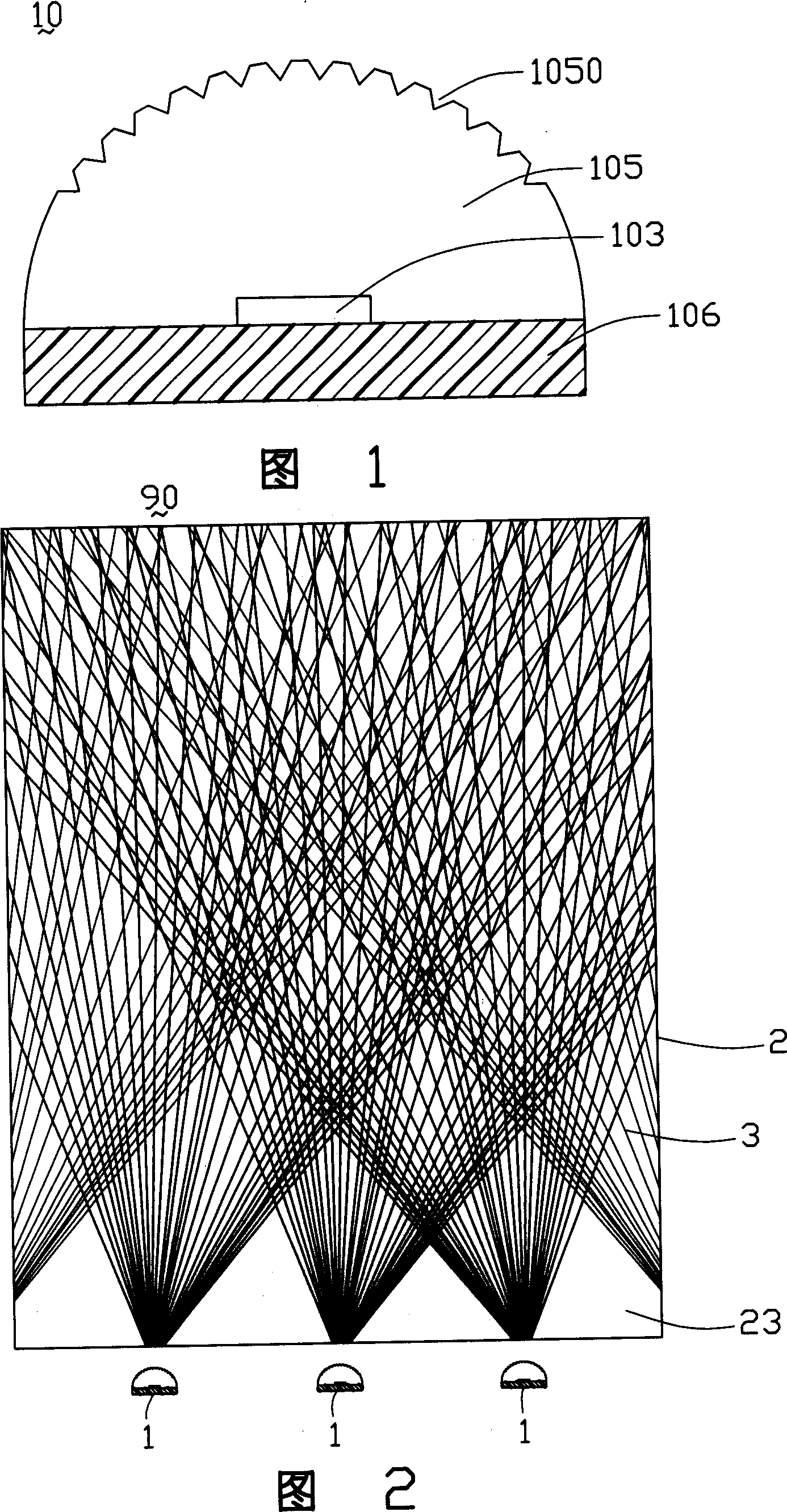

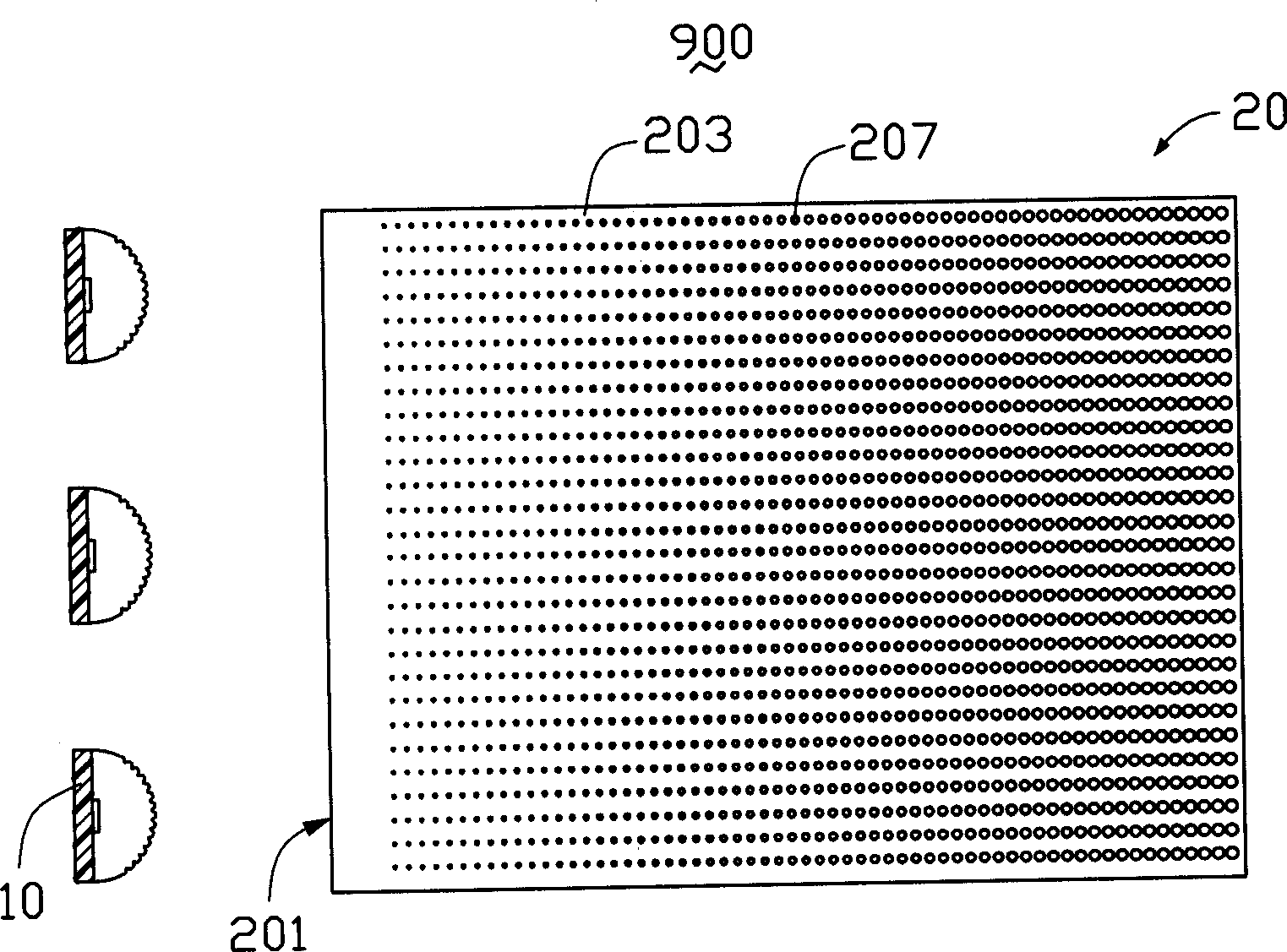

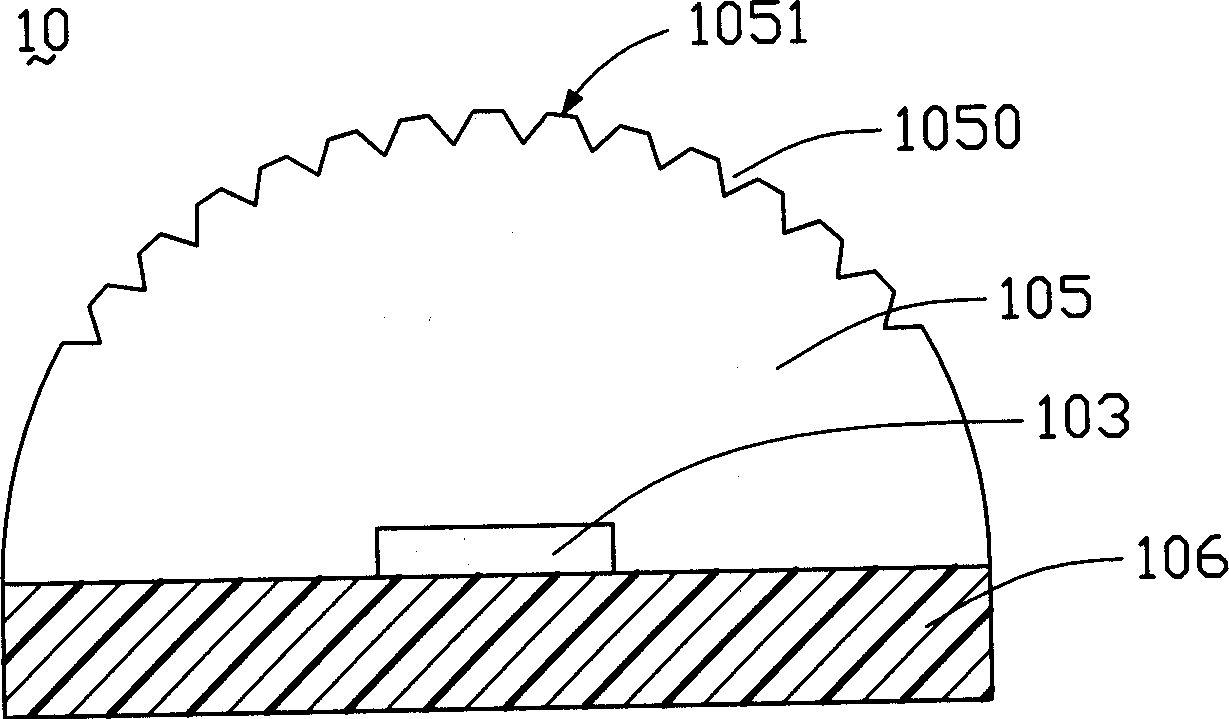

[0013] see image 3 , is a bottom view of the backlight module of the present invention, the backlight module 900 includes a plurality of light emitting diodes 10 and a light guide plate 20 . The plurality of light emitting diodes 10 are used to emit light beams, and the light guide plate 20 is used to guide the transmission direction of the light beams emitted by the plurality of light emitting diodes 10 to convert them into surface light sources for emission. The light guide plate 20 is flat and made of transparent materials such as acrylic, glass or polycarbonate. The bottom surface 203 of. The incident surface 201 is used to receive the light beam emitted by the LED 10 . The exit surface can be processed into a rough surface with a certain roughness. The bottom surface 203 of the light guide plate 20 is provided with a plurality of dots 207 , and the dots 207 are used to improve the luminance and uniformity of the light beam emitted from the light guide plate 20 . The s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com