Electrical pulse generator using pseudo-random pole distribution

A technology of electric pulses and magnetic poles, applied in the direction of electromechanical devices, machines/engines, spark ignition controllers, etc., can solve problems such as hindering larger applications, and achieve short-duration, high-energy effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

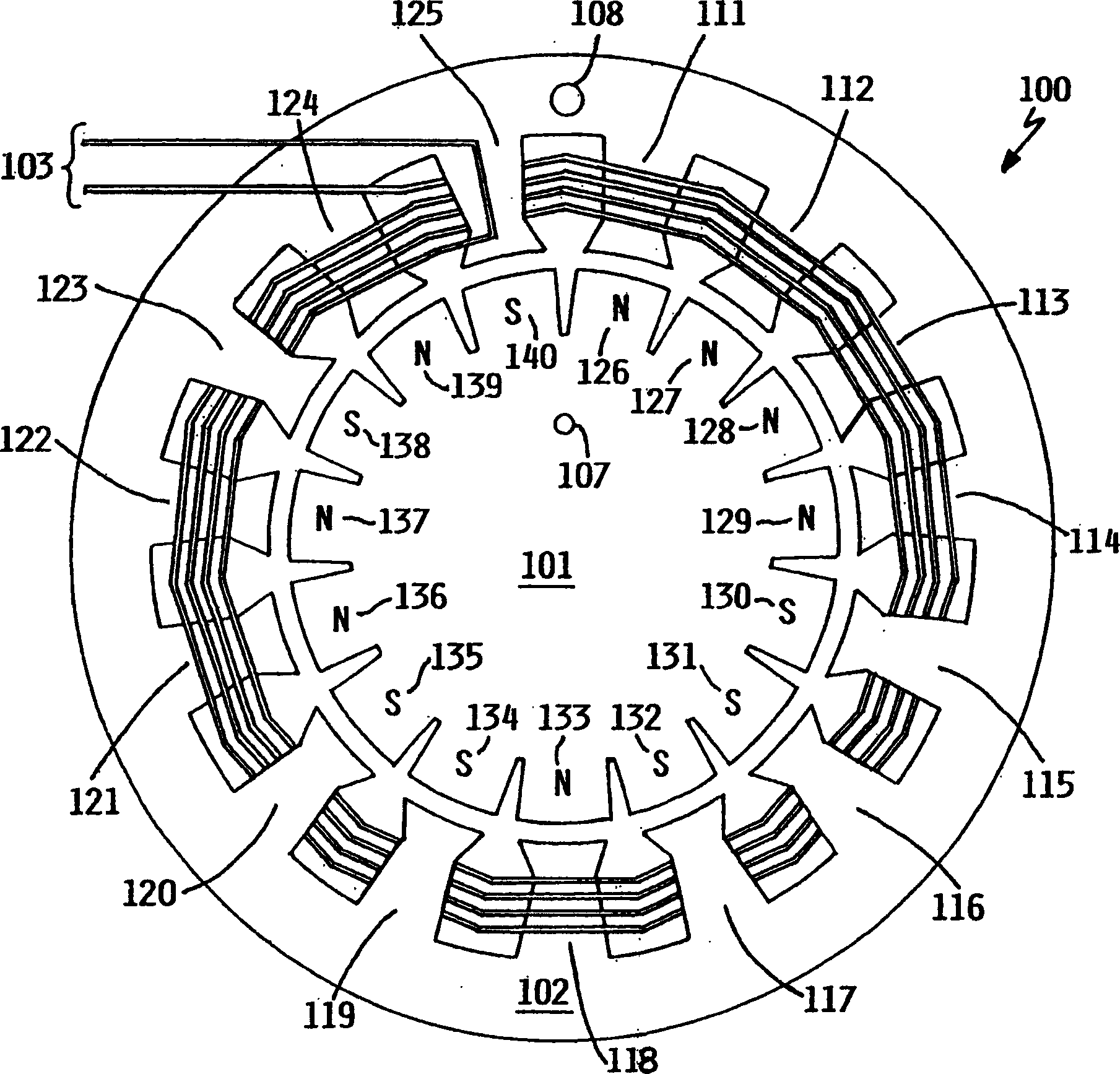

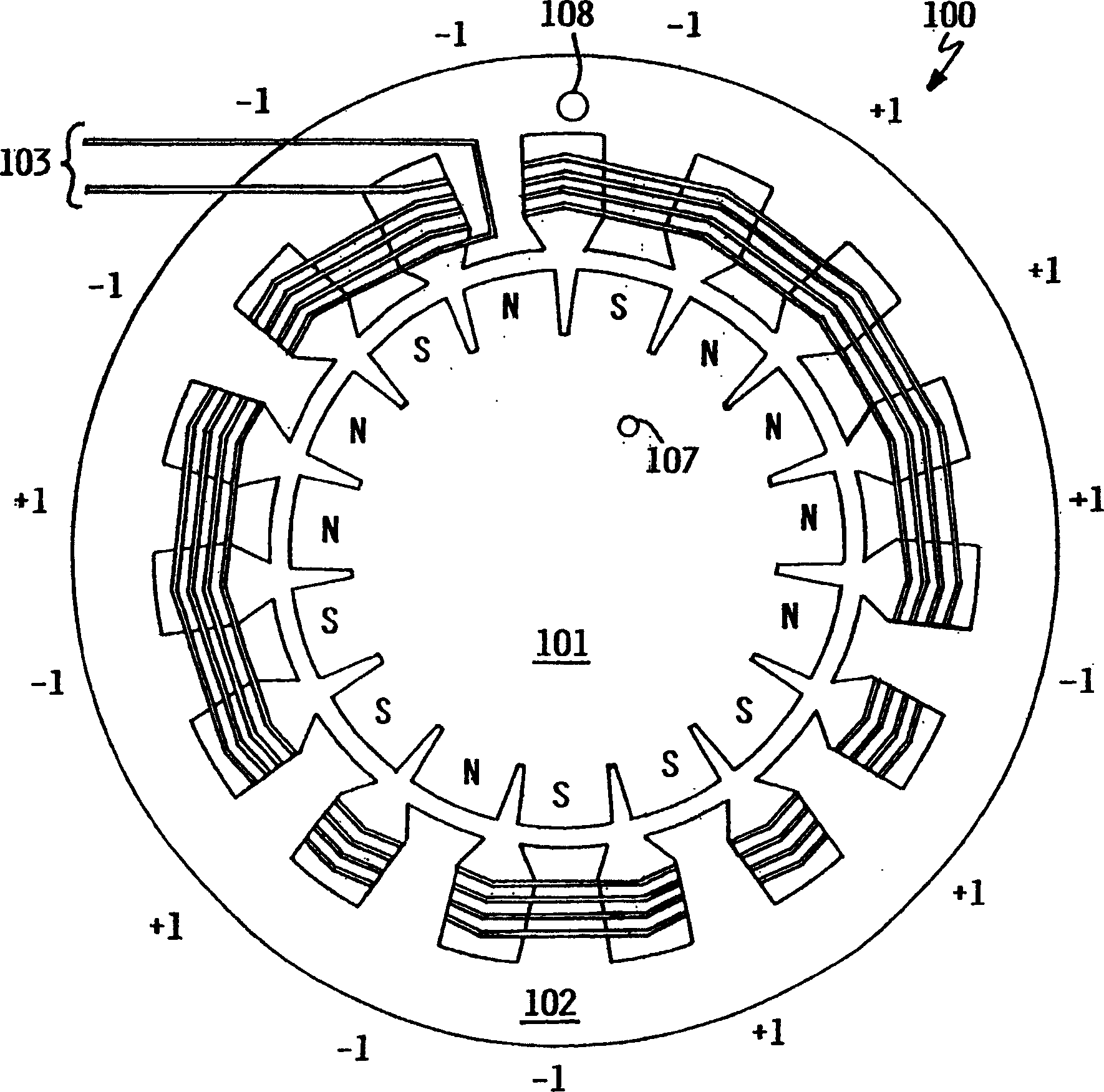

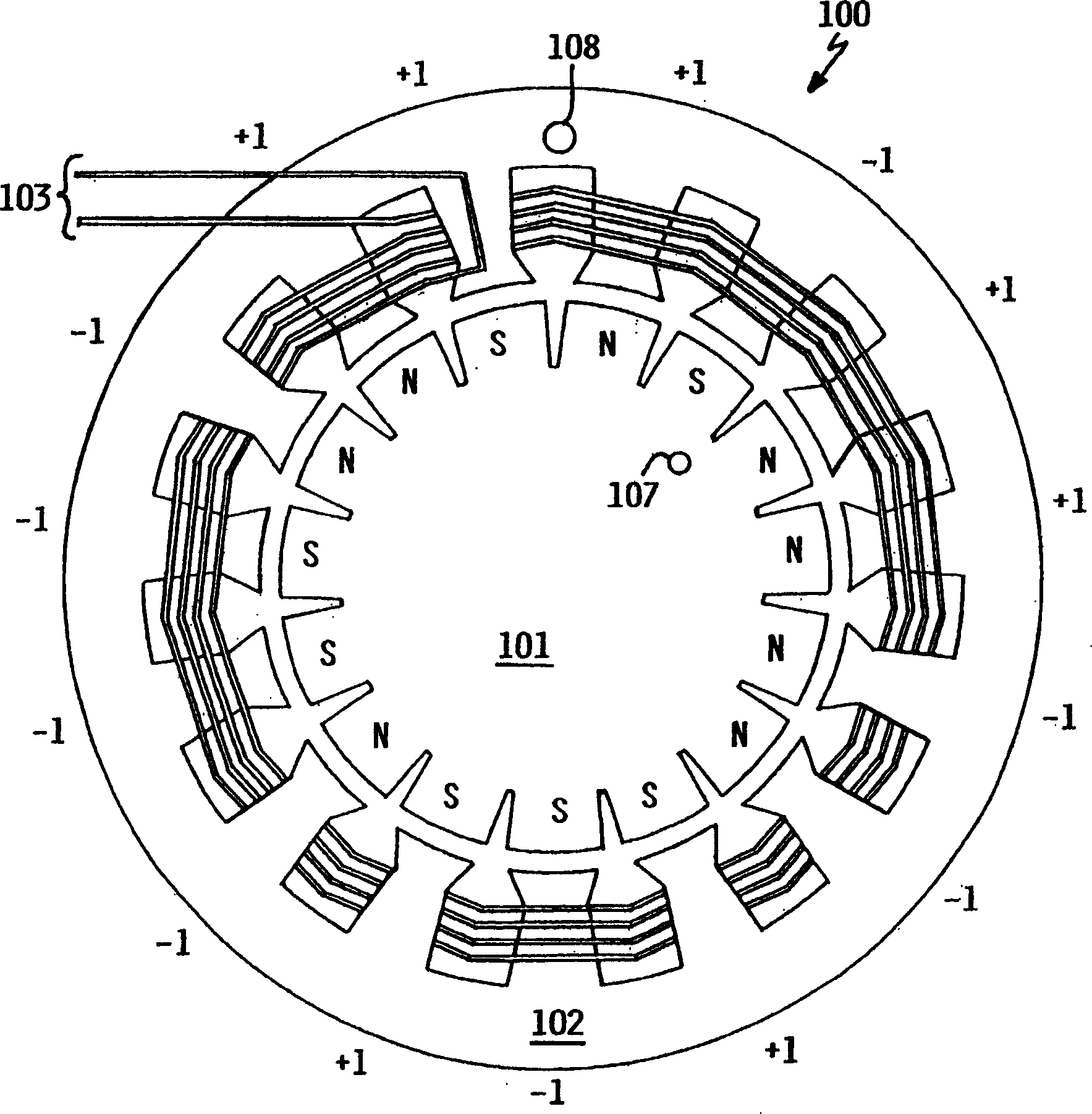

[0031] The embodiment described herein is a rotating electromagnetic device for generating electrical pulses, and some terms used herein have the following meanings. A "rotor" is a physical member that rotates about an axis. A "stator" is a stationary member that does not rotate relative to the shaft. An "armature" is an electrical conductor in which a voltage is induced by a time-varying magnetic field relative to the armature. Because the armature is usually wound in coils or loops, it is sometimes referred to as "armature winding" or "armature coil", it being understood that this is not intended to imply any specific arrangement of the electrical conductors forming the armature. geometric shapes. The armature can be located on the rotor or the stator. The magnetic field driving the armature can actually be a stationary, non-changing field that is "time-varying" with respect to the armature only because the armature is rotating. A "field winding" or "field coil" is an el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com