Device and method for pressing tobacco, ribs or the like

A technology of analogues and equipment, which is applied in the field of stems or analogues, and compacted tobacco, which can solve the problems of fine groove sealing and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

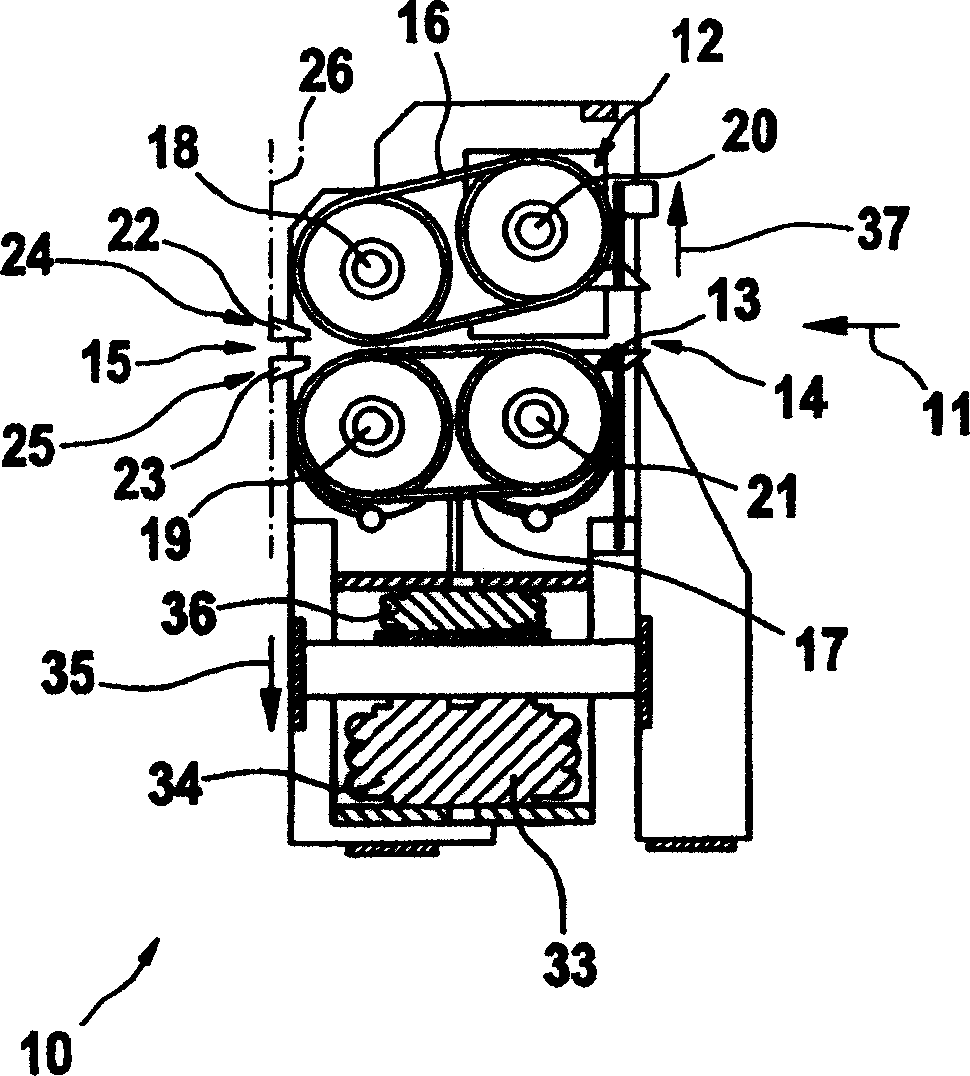

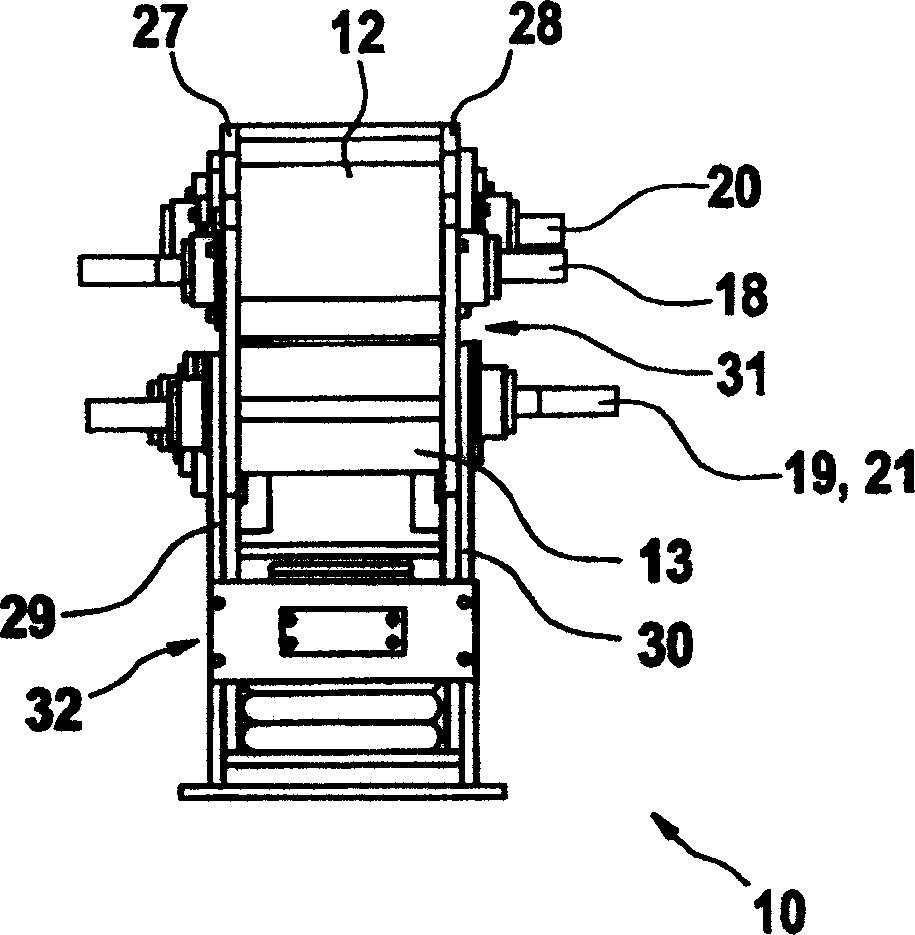

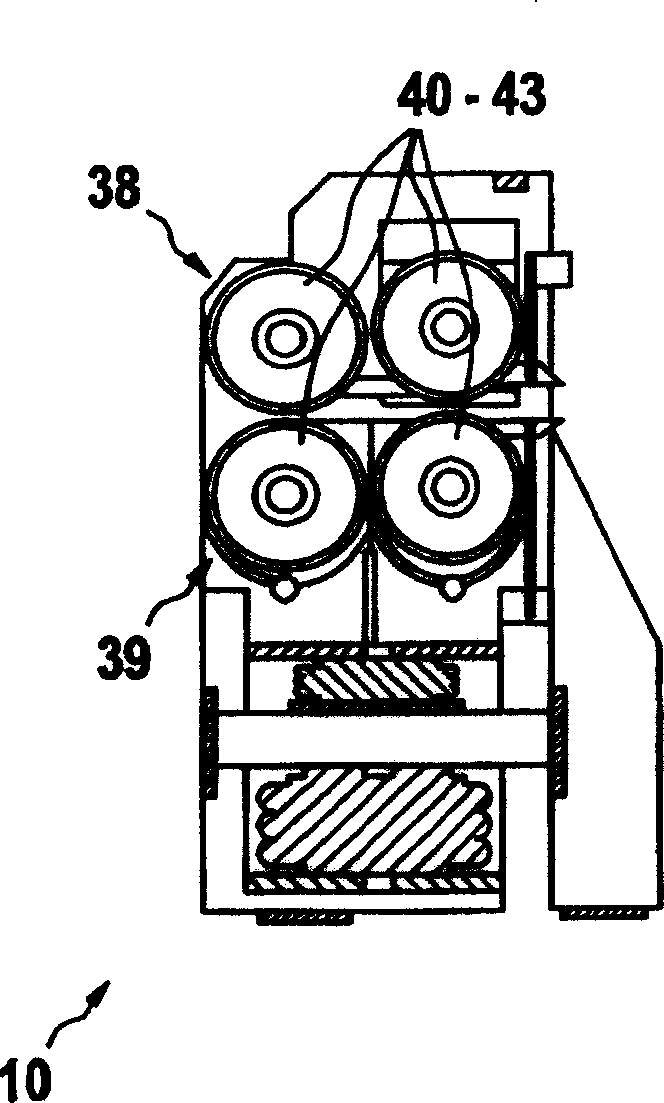

[0025] The apparatus shown is a compacting device for compacting tobacco in the manufacture of cigarettes and the like.

[0026] figure 1 A first embodiment of a device 10 for compacting tobacco and the like is shown, the so-called primary compacting means. The device 10 is usually connected to a pre-compaction device (not shown) on the input side, ie at the front of the device 10 in the direction of transport of the tobacco indicated by arrow 11 . On the output side, ie at the rear of the device 10 in the conveying direction indicated by arrow 11 , a tobacco cutting device (not shown) is usually arranged. The device 10 comprises two pressing elements 12 and 13 designed on the one hand to transport tobacco from the inlet 14 to the outlet 15 and on the other hand to compress the tobacco. exist figure 1 and 2 In the illustrated embodiment, the pressing elements 12 and 13 are designed as chains 16 , 17 each guided around drive shafts 18 , 19 (or drive rollers) and around defl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com