Light conducting board and back light module

A backlight module and light guide plate technology, applied in optics, nonlinear optics, instruments, etc., can solve the problems of high cost of light guide plate, high cost of backlight module, low light utilization rate, etc., achieve low cost, omit glue Process, the effect of high light utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

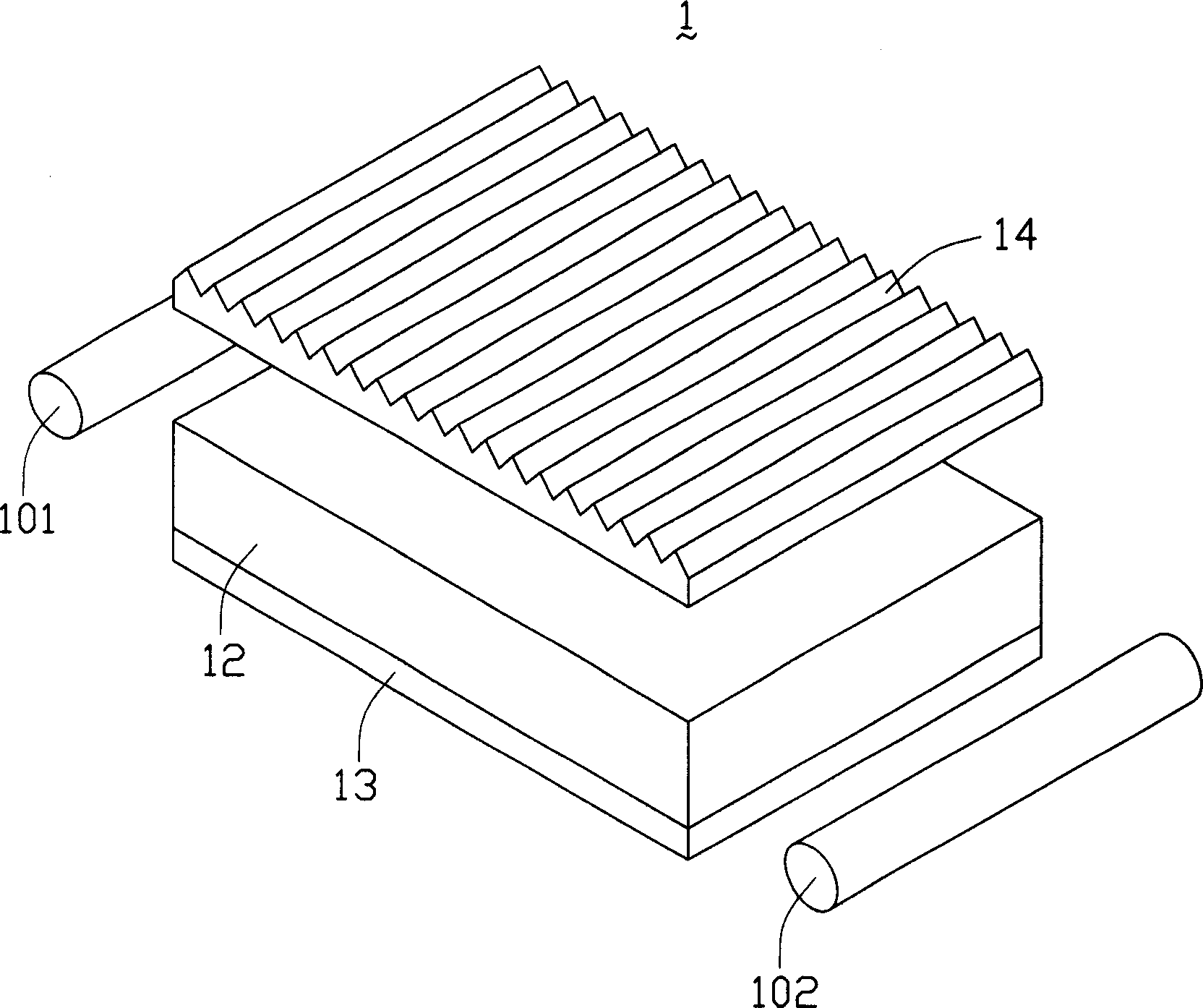

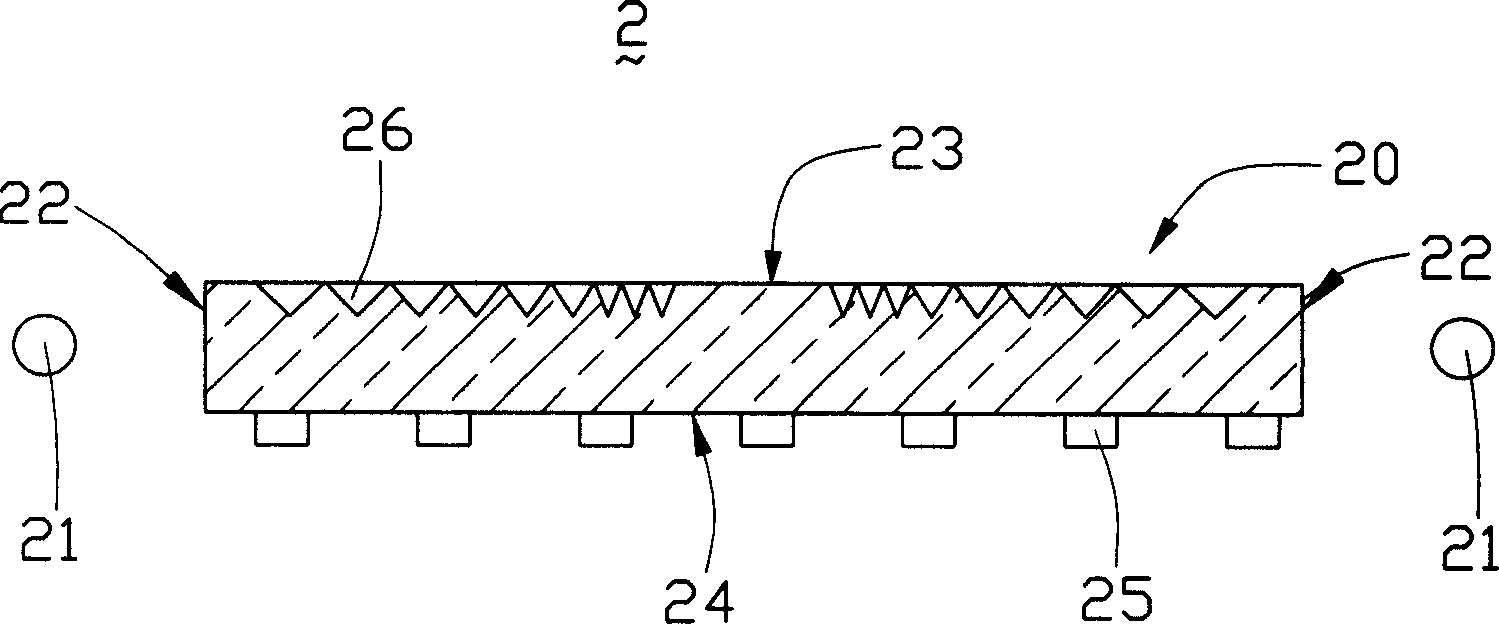

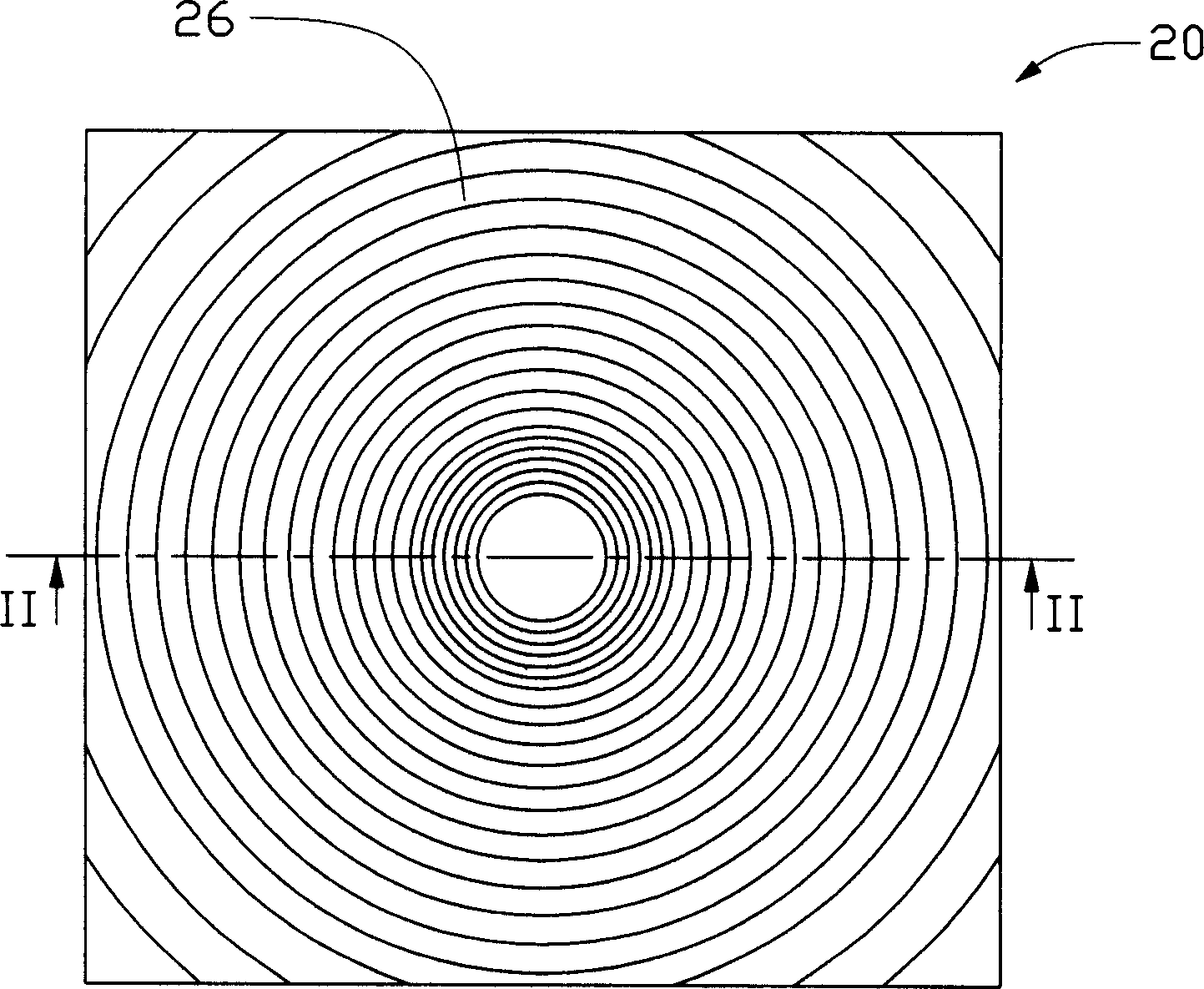

[0013] Please also refer to figure 2 and image 3 , are respectively the side view and the top view of the light guide plate of the first embodiment of the backlight module of the present invention. The backlight module 2 includes a light guide plate 20 and two light sources 21 . The light guide plate 20 is flat, and its material can be acrylic resin, polycarbonate, polyethylene resin or glass. The light guide plate 20 includes two opposite light incident surfaces 22 , a light exit surface 23 adjacent to the two light incident surfaces 22 , and a bottom surface 24 opposite to the light exit surfaces 23 . Wherein, the light-emitting surface 23 is provided with concentric circular grooves 26 with varying pitches. The concentric circular grooves 26 are concentric circular structures formed by gradually spreading outward from the center of the light guide plate 20, wherein the cross-section of each groove is V It can also be trapezoidal, arc-shaped, elliptical, etc. The conce...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com