Aluminum cooking ware and its surface treatment process

A technology for cooking utensils and surface treatment, which is applied in the field of aluminum cooking utensils and their surface treatment technology, and can solve the problems of low temperature resistance, short service life, and low hardness of fluororesin

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

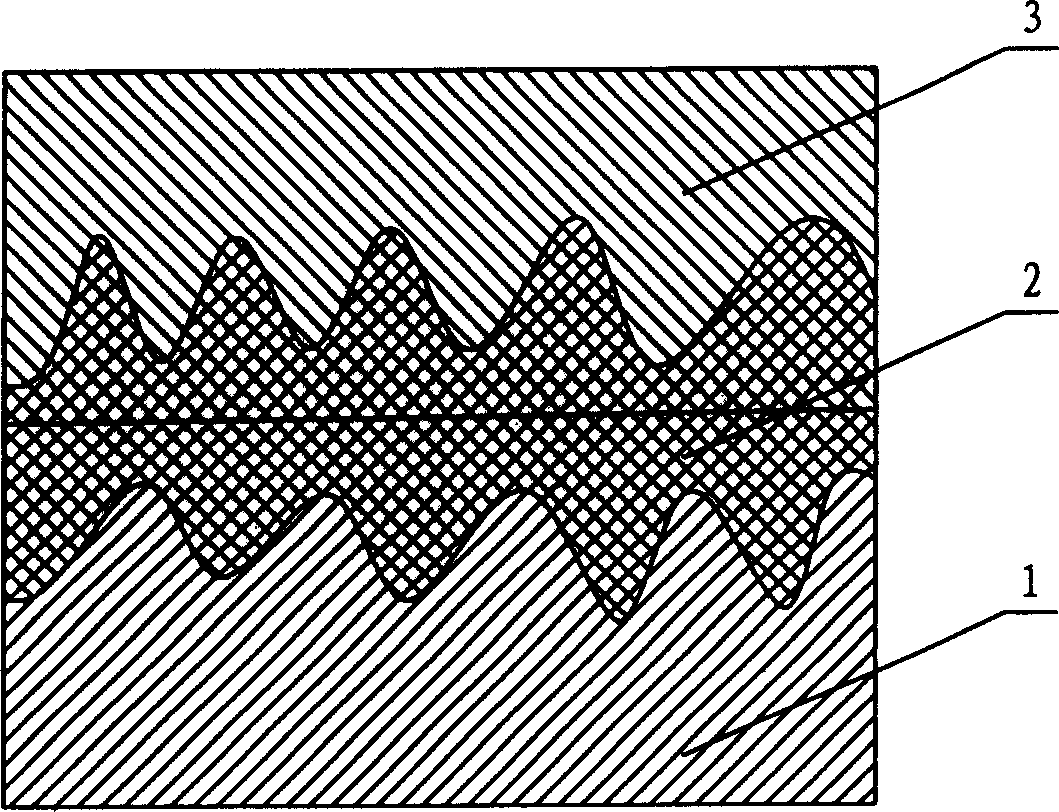

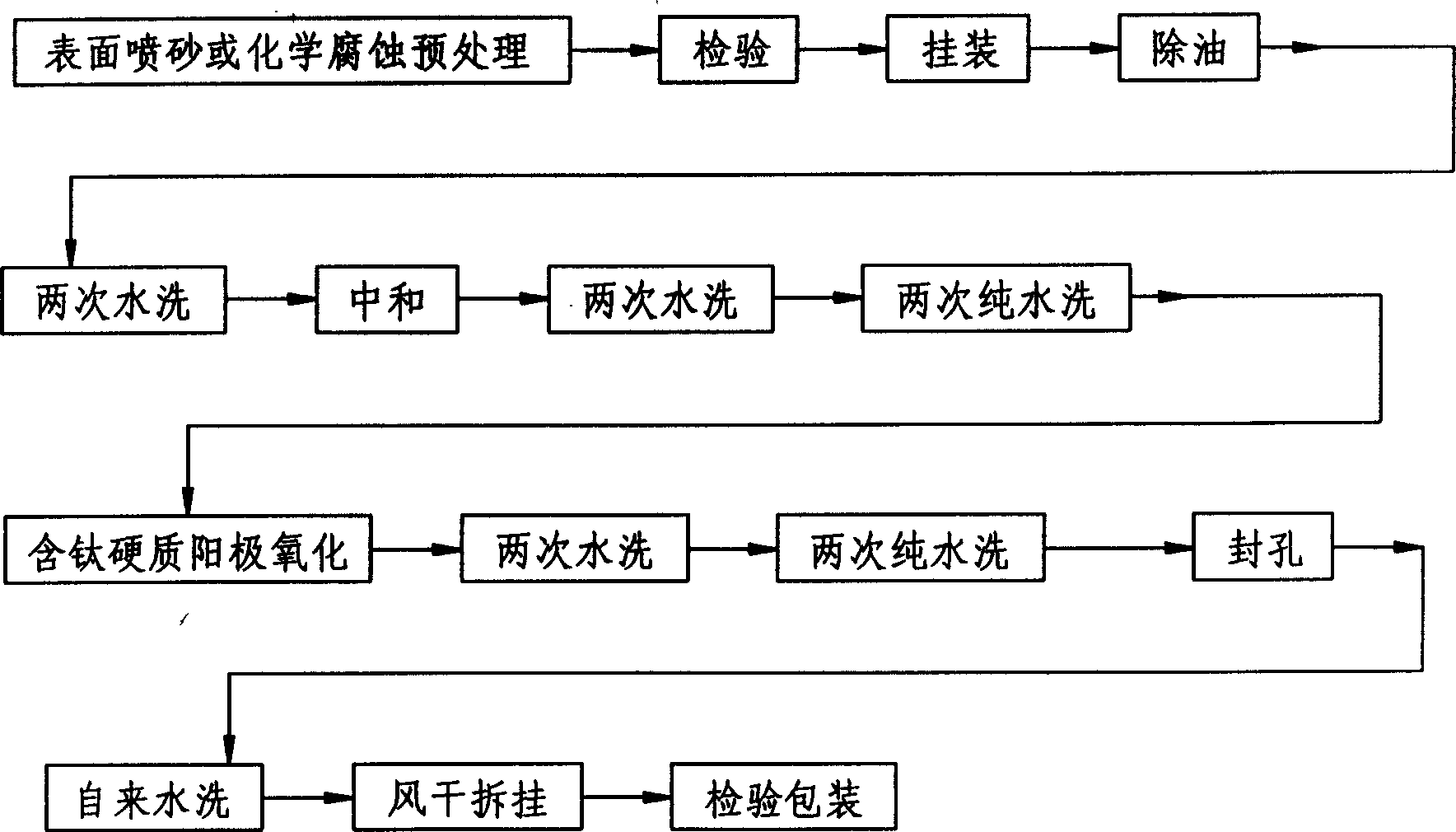

[0011] see Figure 1-2 , the aluminum cooking utensils and their surface treatment process, the stamped pure aluminum or aluminum alloy utensils 1 are subjected to surface sandblasting pretreatment: coarse steel grit, steel balls, steel wire grains, or the three can be used Mix and blast the surface of the container with high-pressure impact to produce concave holes with different diameters or depths, unevenness and uneven thickness. The surface treatment can also be chemical etching, such as immersing the vessel in a solution of trisodium phosphate. Then, set the surface area to 4.8m 3 The container is connected with pure titanium as the anode, and the cathode is made of copper or lead, and placed in a 10m 3 In the acid solution, the acid solution is sulfuric acid, oxalic acid or a mixed acid thereof, and its working temperature is 5°C to 20°C. The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com