Liquid crystal cell process for in-plane switching mode liquid crystal display device

一种液晶单元、液晶显示的技术,应用在静态指示器、半导体/固态器件制造、仪器等方向,能够解决液晶单元VIb不能正常工作等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] Reference will now be made in detail to embodiments of the invention, examples of which are illustrated in the accompanying drawings. Wherever possible, the same reference numbers will be used throughout the drawings to refer to the same or like parts.

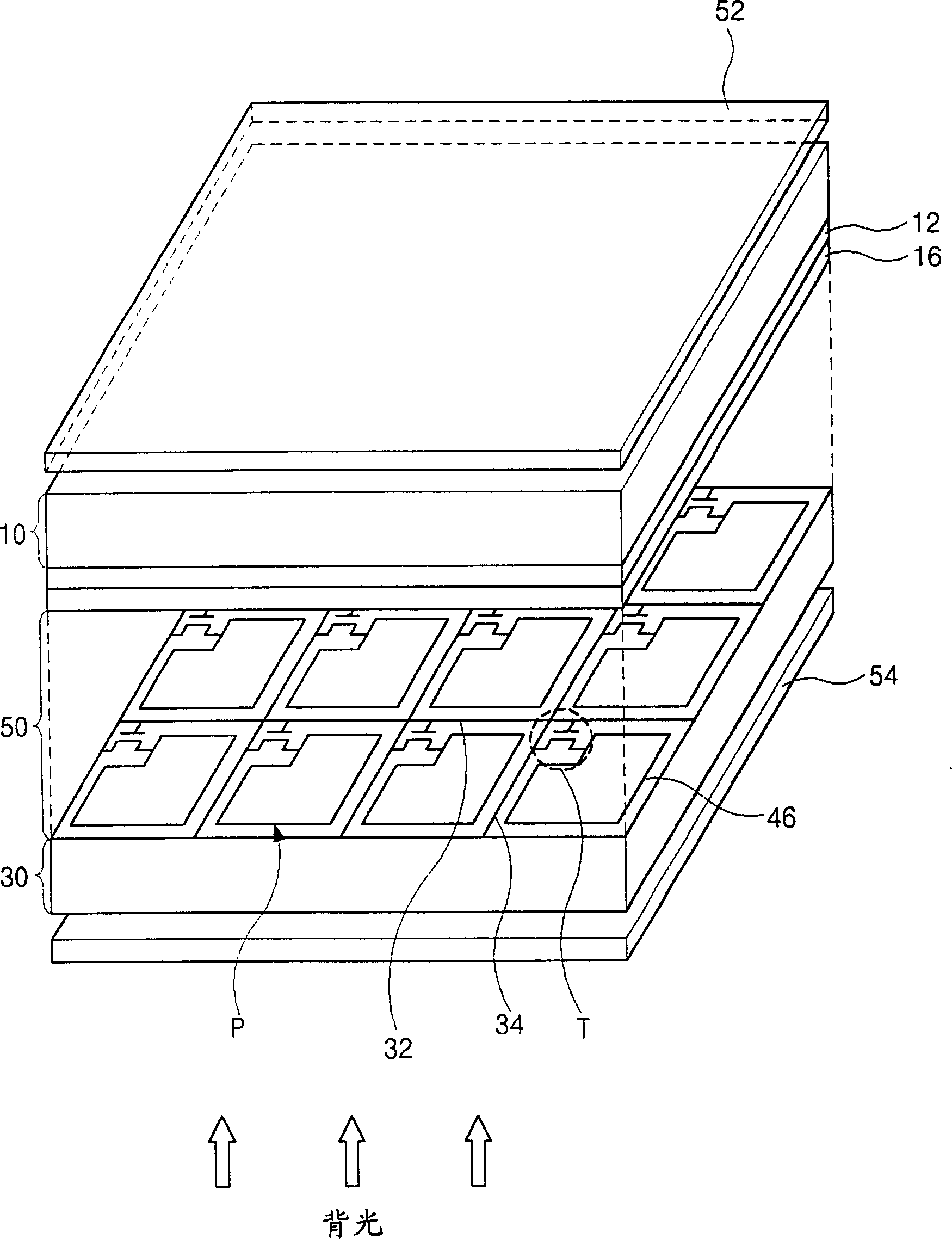

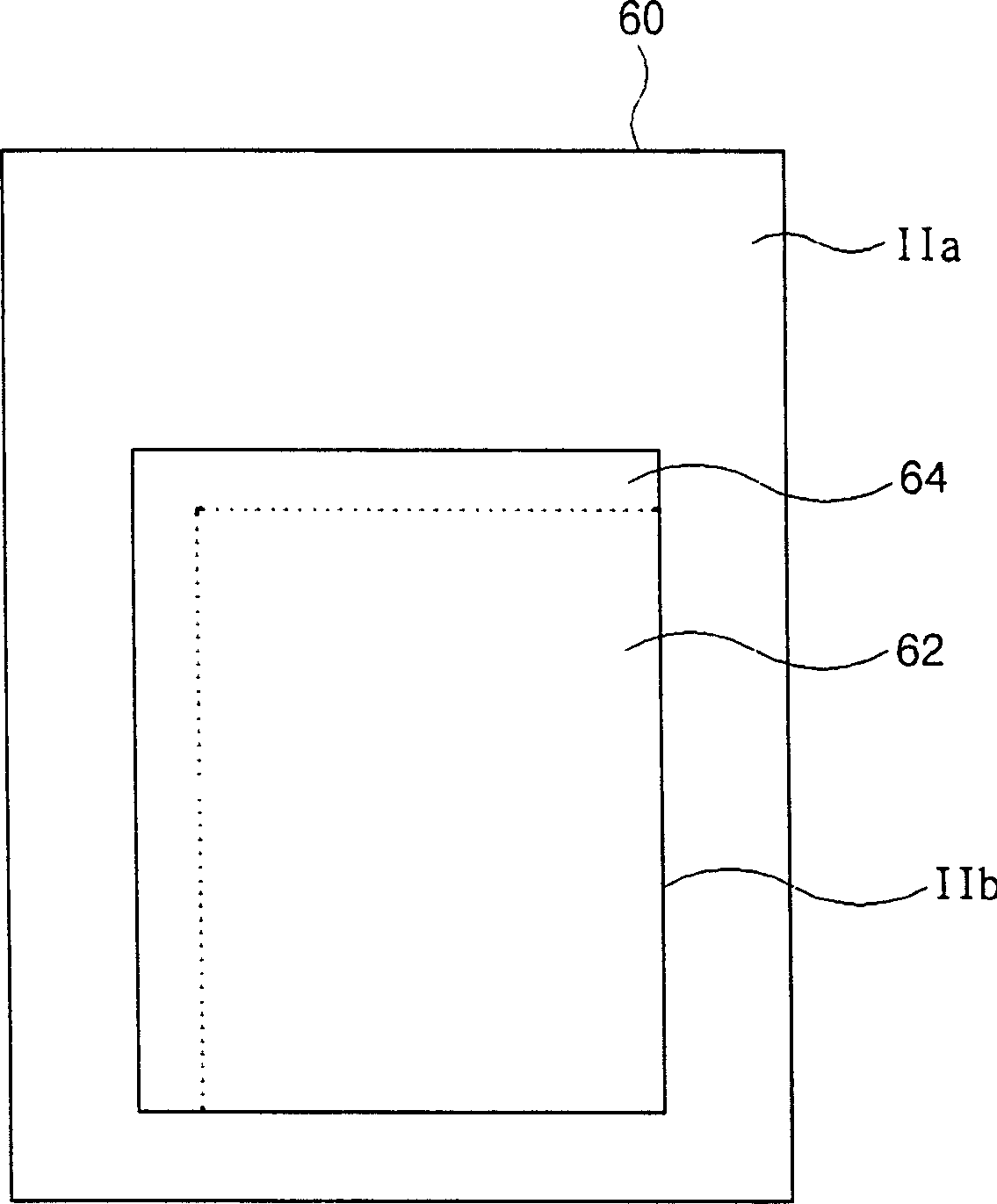

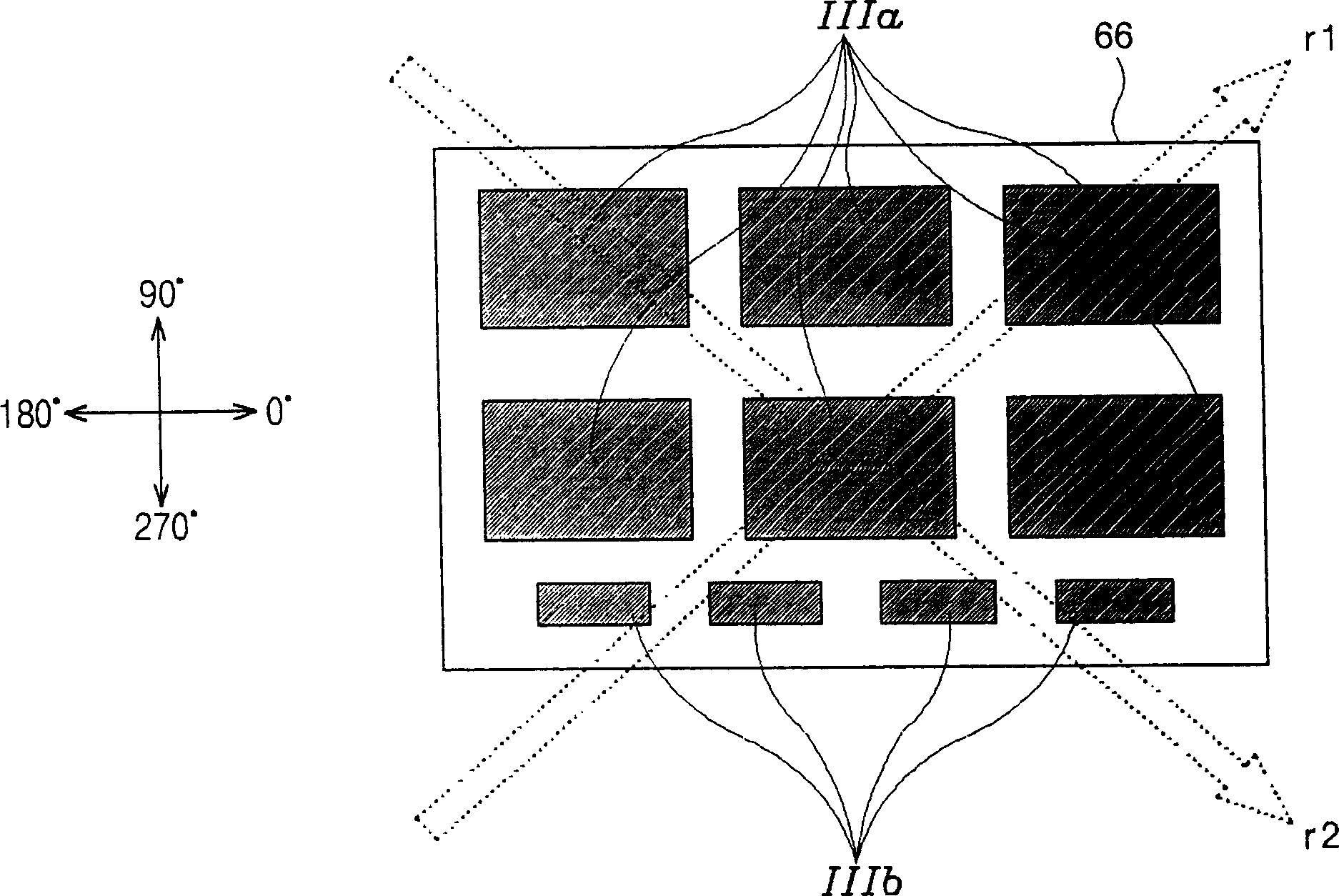

[0045] Figure 7 is a diagram representing an MMG (multi-module-on-glass) type setup of a liquid crystal cell for an IPS-LCD having a circular common electrode and a circular pixel electrode according to the invention, Figure 8 is a plan view showing one pixel of the array substrate having a circular common electrode and a circular pixel electrode according to the present invention. Such as Figure 7 As shown, a plurality of first liquid crystal cell regions VIIa are provided on the bare glass 110 , for example, a plurality of 30-inch liquid crystal cells. In addition, a plurality of second liquid crystal cell regions VIIb, such as a plurality of 18.1-inch liquid crystal cells, are also provided on the bare glass 110 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com