Self-adaptive grate element for cooling high temperature bulk material

An adaptive, high-temperature technology, applied in the field of grate components, can solve the problems of occupying the internal space of the equipment, uneven distribution, and increasing the complexity of the equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

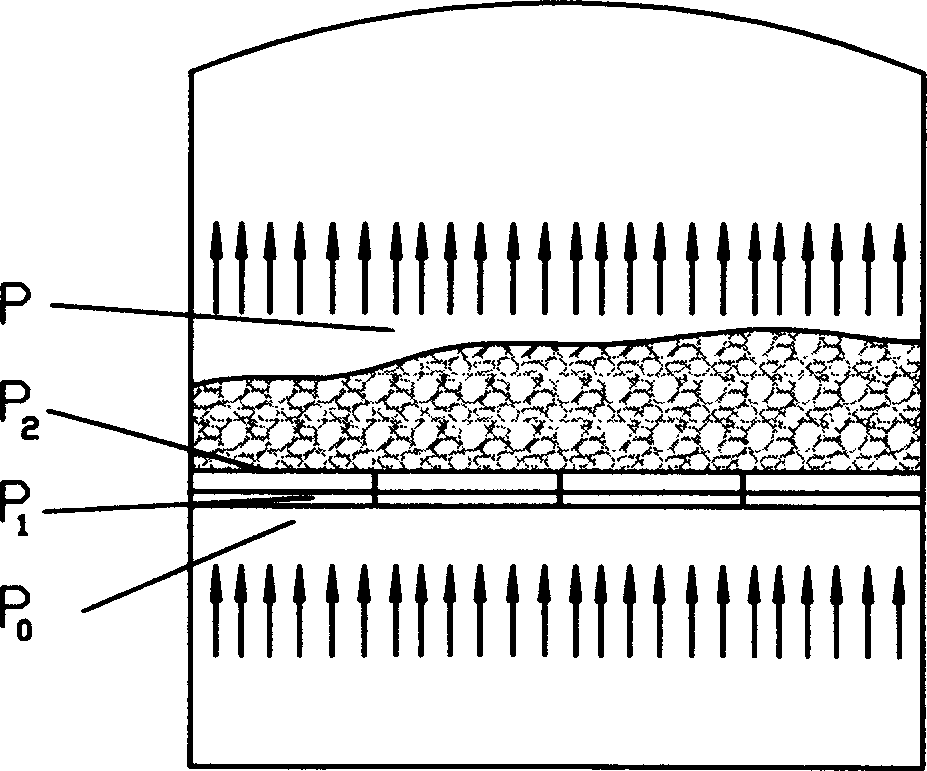

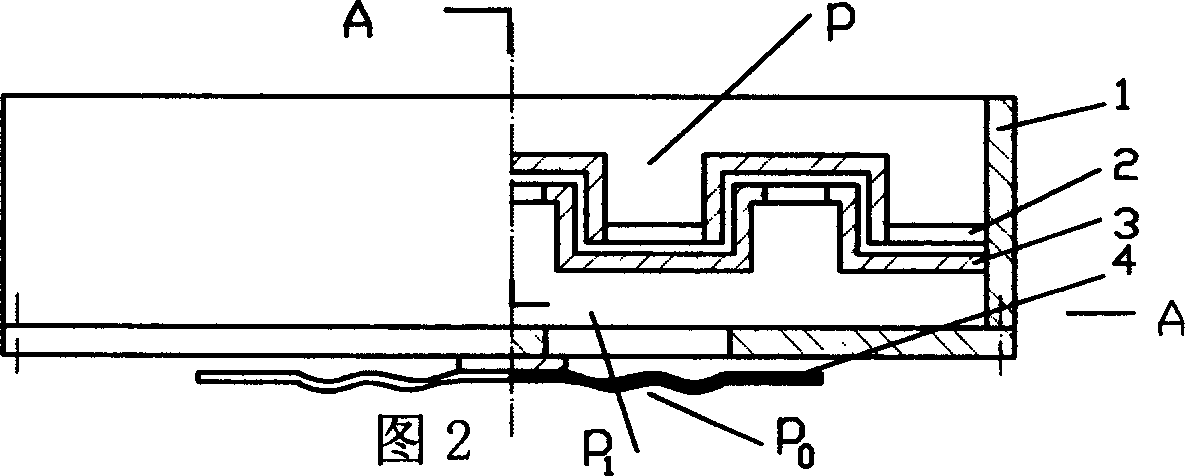

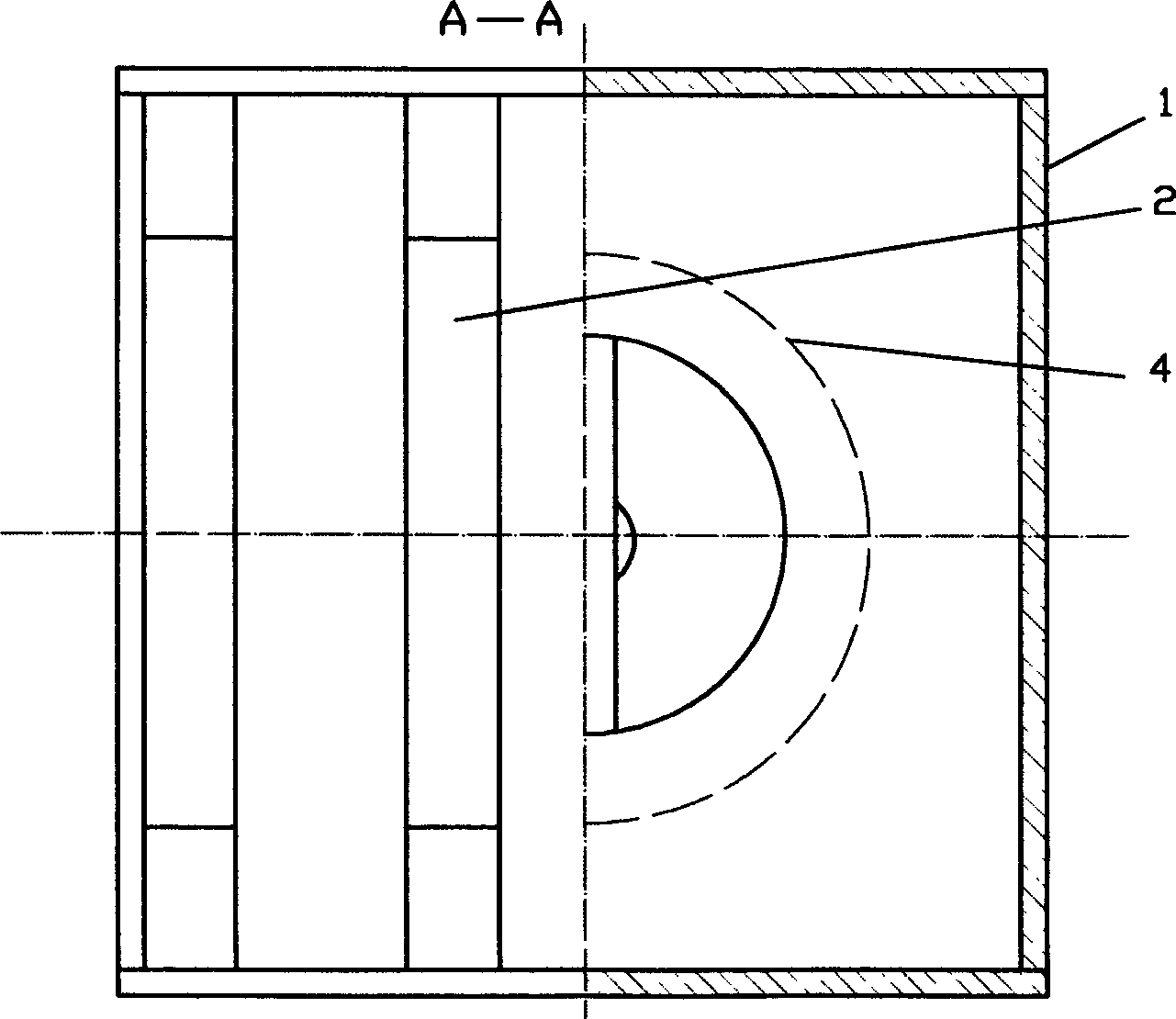

[0014] figure 1 It shows a cross-sectional view of a grate cooler. There are many grate plates on the surface of the grate bed, and there is a large clinker conveying cavity on it. The air chamber under the grate bed is also relatively large, and the clinker conveying cavity Gas pressure P and gas pressure P in the air chamber 0 Controlled by the fan, these two pressure values can be regarded as constant during the working period. When the particle size of cement clinker on a certain grate plate is large or the thickness of the material layer is thin, the resistance of the material layer to the gas will become smaller. At this time, if the gas penetrates the material layer from bottom to top without additional restrictions, The flow rate of this grate plate will increase, and in serious cases, a gas short circuit will occur. At this time, since the pressure P on the upper part of the material layer remains basically unchanged, the flow resistance of the material layer beco...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com