Controlling hydraulic actuating cylinders in roll stands

A rolling mill rack and regulating cylinder technology, applied in hydraulic program control, electric fluid pressure control, fluid pressure control, etc., can solve the problem of not considering the change in the performance of the regulating circuit, so as to prevent pressure drop and reliable hydraulic locking Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

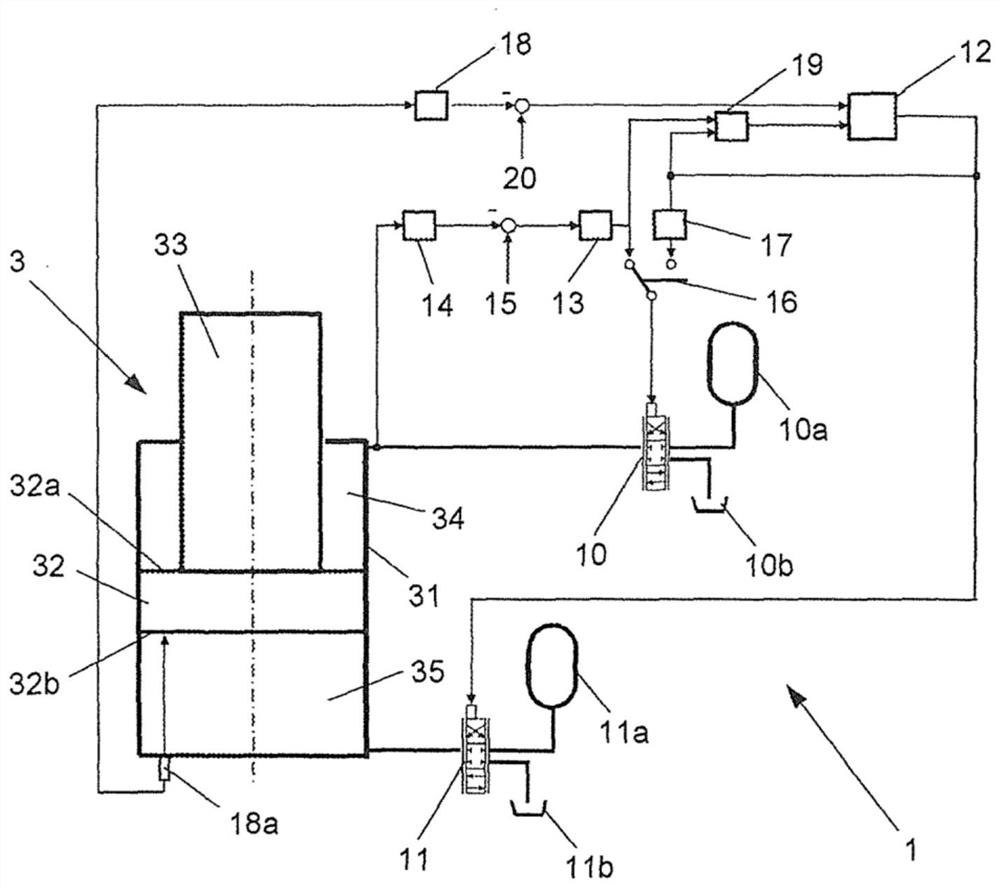

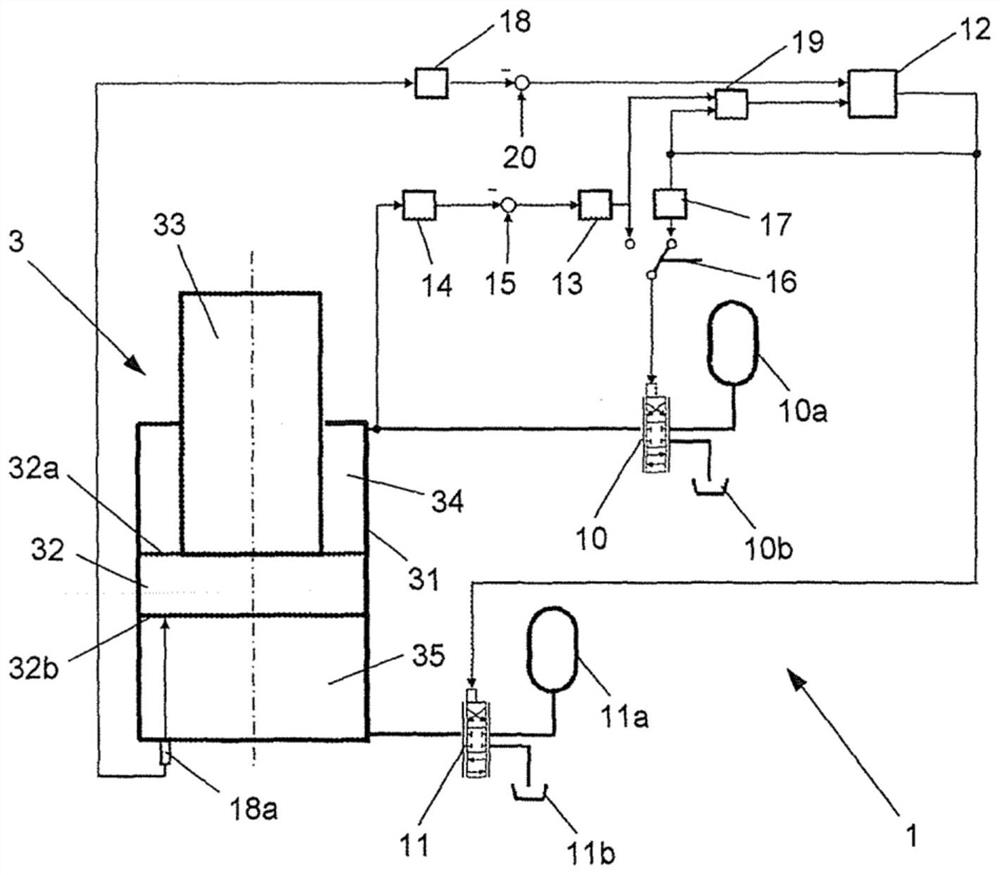

[0031] A preferred exemplary embodiment is described below with reference to the drawings. In this case, identical, similar or identically acting elements in different figures are provided with the same reference signs, and repeated descriptions of elements are partially omitted in order to avoid redundancy.

[0032] Figure 1a and Figure 1b is a schematic diagram of a hydraulic regulating circuit 1 for actuating a regulating cylinder 3 arranged for use in a rolling mill stand, Figure 1a It shows that the hydraulic regulating circuit is in the state of pressure regulation, Figure 1b The hydraulic regulating circuit is shown in a position regulating state.

[0033] The adjusting cylinder 3 is preferably an adjusting cylinder for an upright rolling stand, which has a cylindrical housing 31 in which a piston 32 is displaceably mounted. In this exemplary embodiment, the adjusting cylinder 3 has a piston rod 33 on the side of the piston 32, so that the piston 32 divides the ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com