Two-phase flow conveying transferring and sand sucking set equipment facilitating multi-direction adjustment

A complete set of equipment, multi-directional technology, applied in the direction of mechanical equipment, pipeline system, gas/liquid distribution and storage, etc., can solve the problems of time-consuming, laborious and inconvenient transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

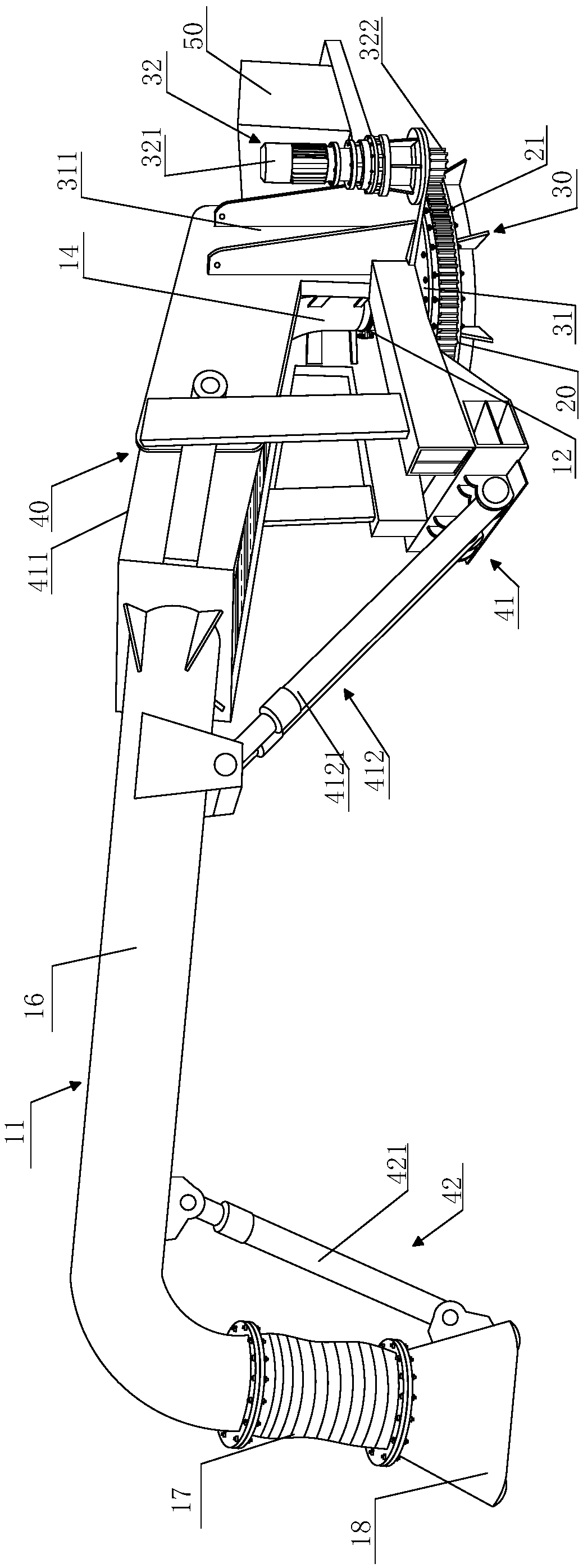

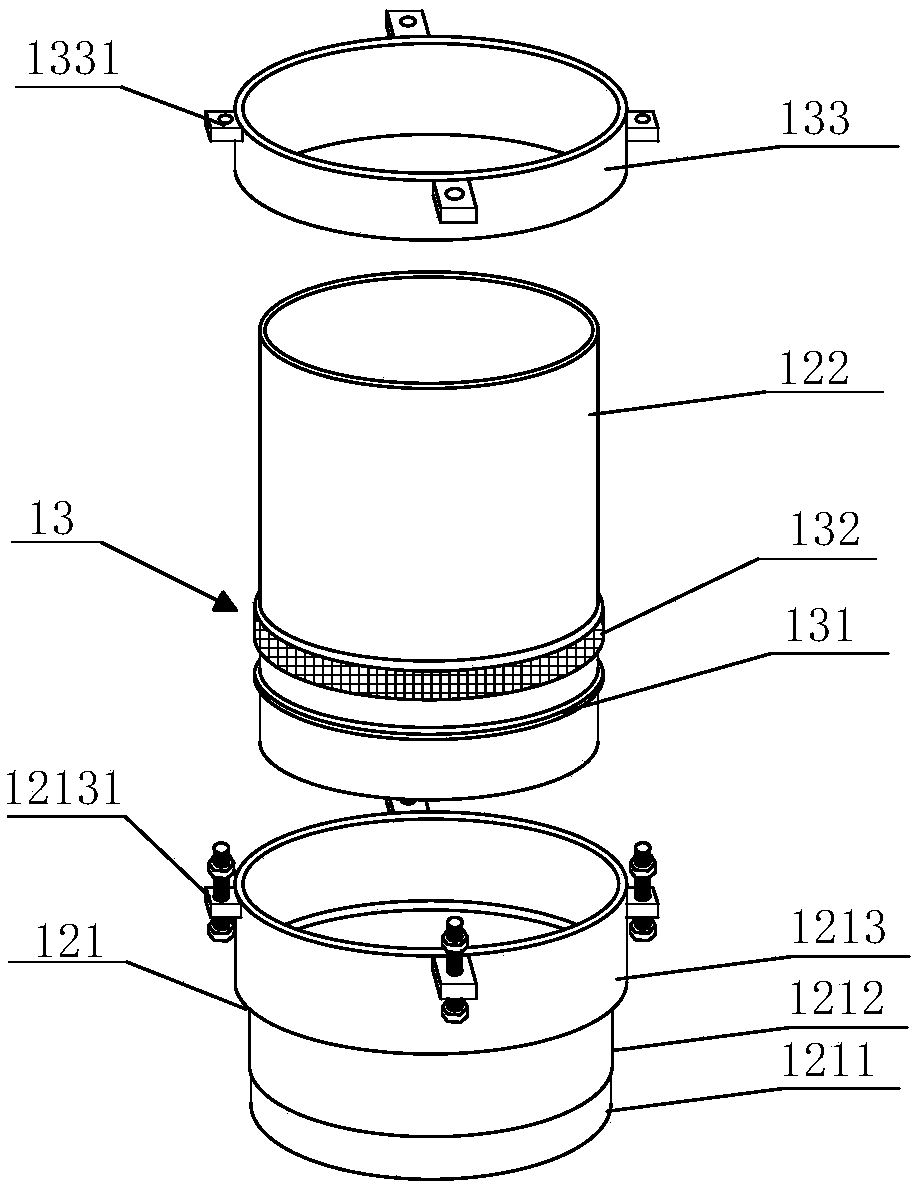

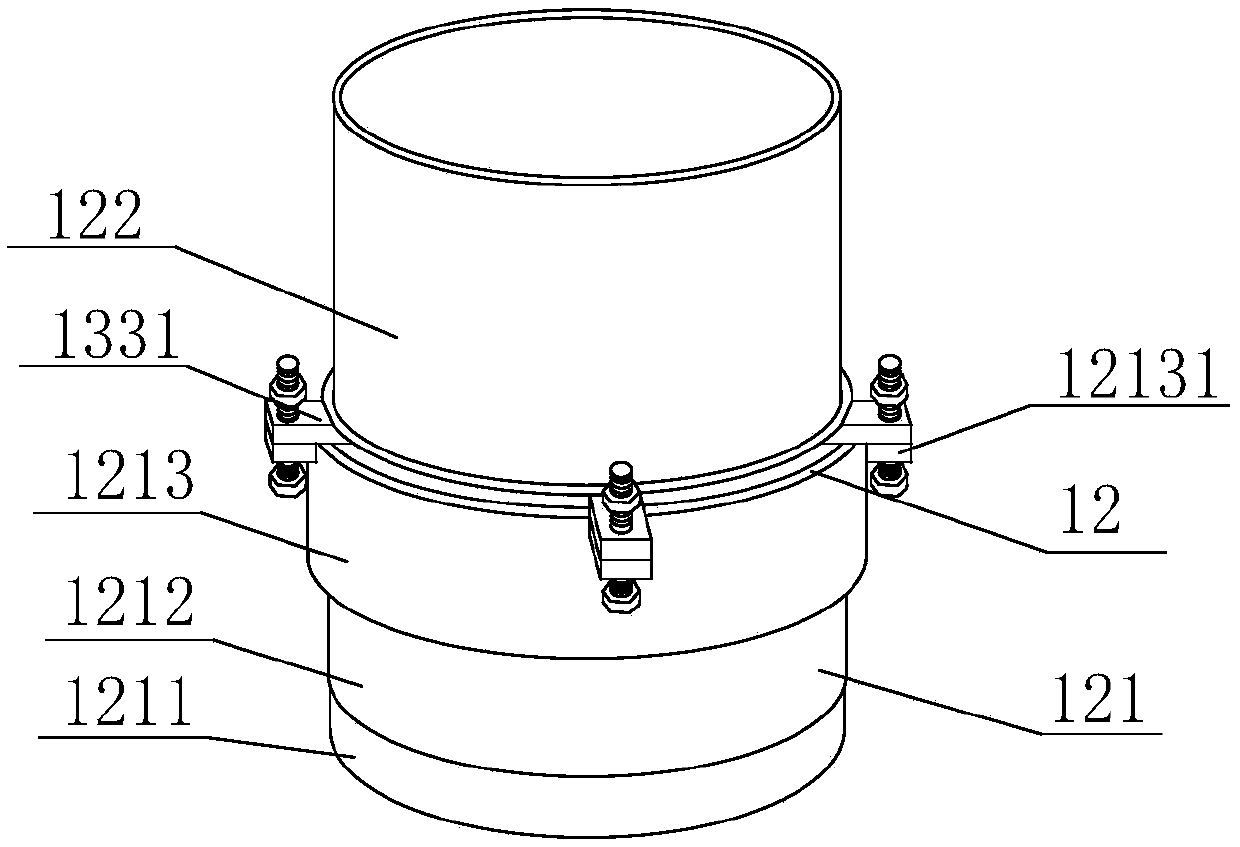

[0041] Such as Figure 1-3 As shown, a complete set of transshipment and sand suction equipment for two-phase flow transportation that is convenient for multi-directional adjustment, the equipment includes a sand suction pump 10 and a sandblasting pipe 11, and the equipment also includes a base 20 and a horizontal rotation device 30 that rotates around the base 20 , the sandblasting pipe 11 is fixedly connected with the horizontal rotating device 30, and the sand inlet end of the sandblasting pipe 11 passes through the base 20 and is connected with the outlet of the sand suction pump 10 through the joint 12, and the sand outlet end of the sandblasting pipe 11 is away from One end of the base 20 is suspended; the sandblasting pipe 11 is provided with a sandblasting adjustment device 40; the joint 12 includes an outer pipe 121 connected to the sand outlet end of the sand suction pump 10 and an inner pipe sleeved in the outer pipe 121 122 , a sealing mechanism 13 is provided betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com