Device for keeping a cold-rolled strip dry in the outlet of strip rolling mills

A technology for cold-rolled strips and strips, applied in workpiece cleaning devices, guiding/positioning/aligning devices, rolls, etc., to solve problems such as disturbing noise, complexity, and energy consumption by known devices and measures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

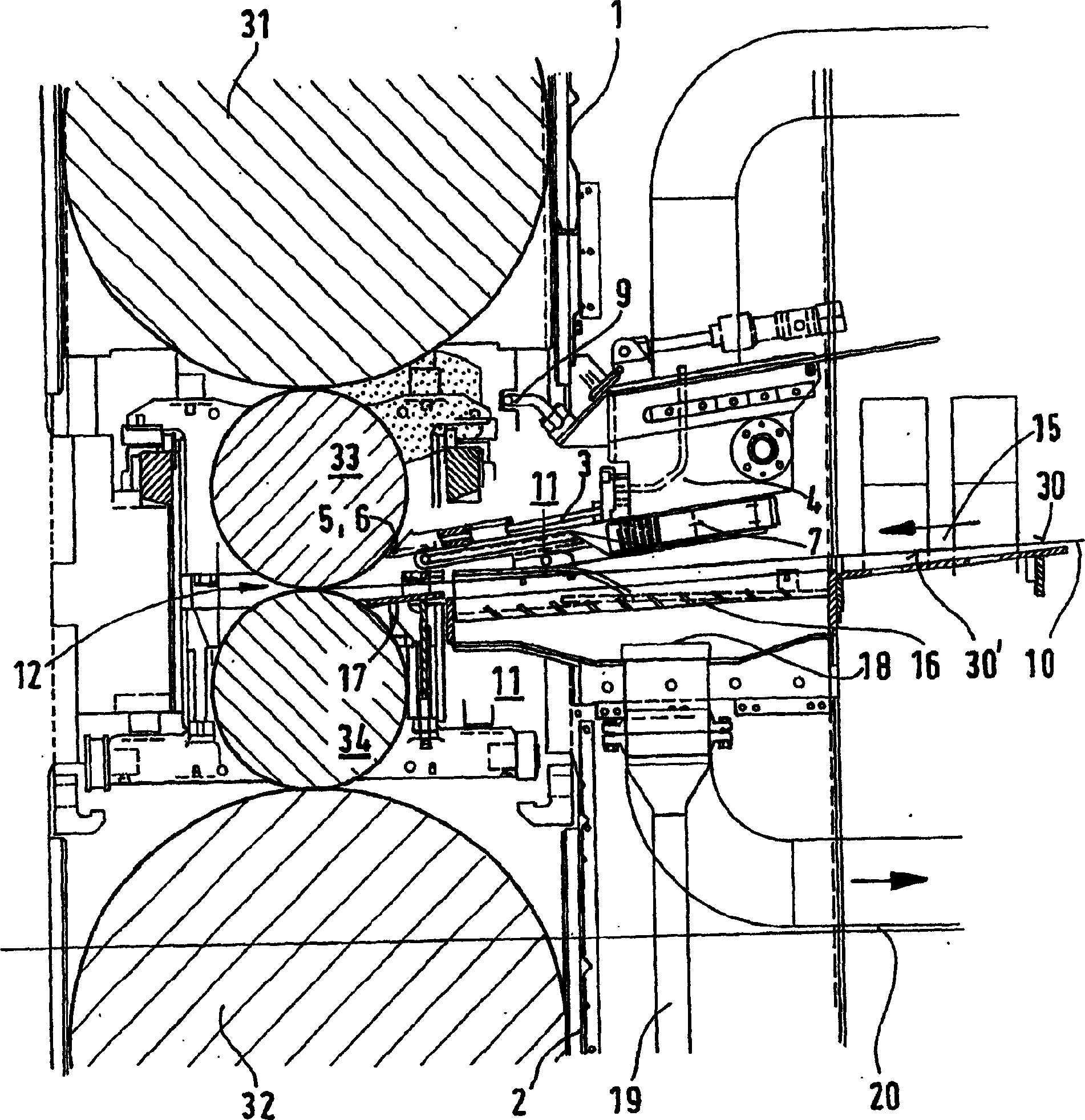

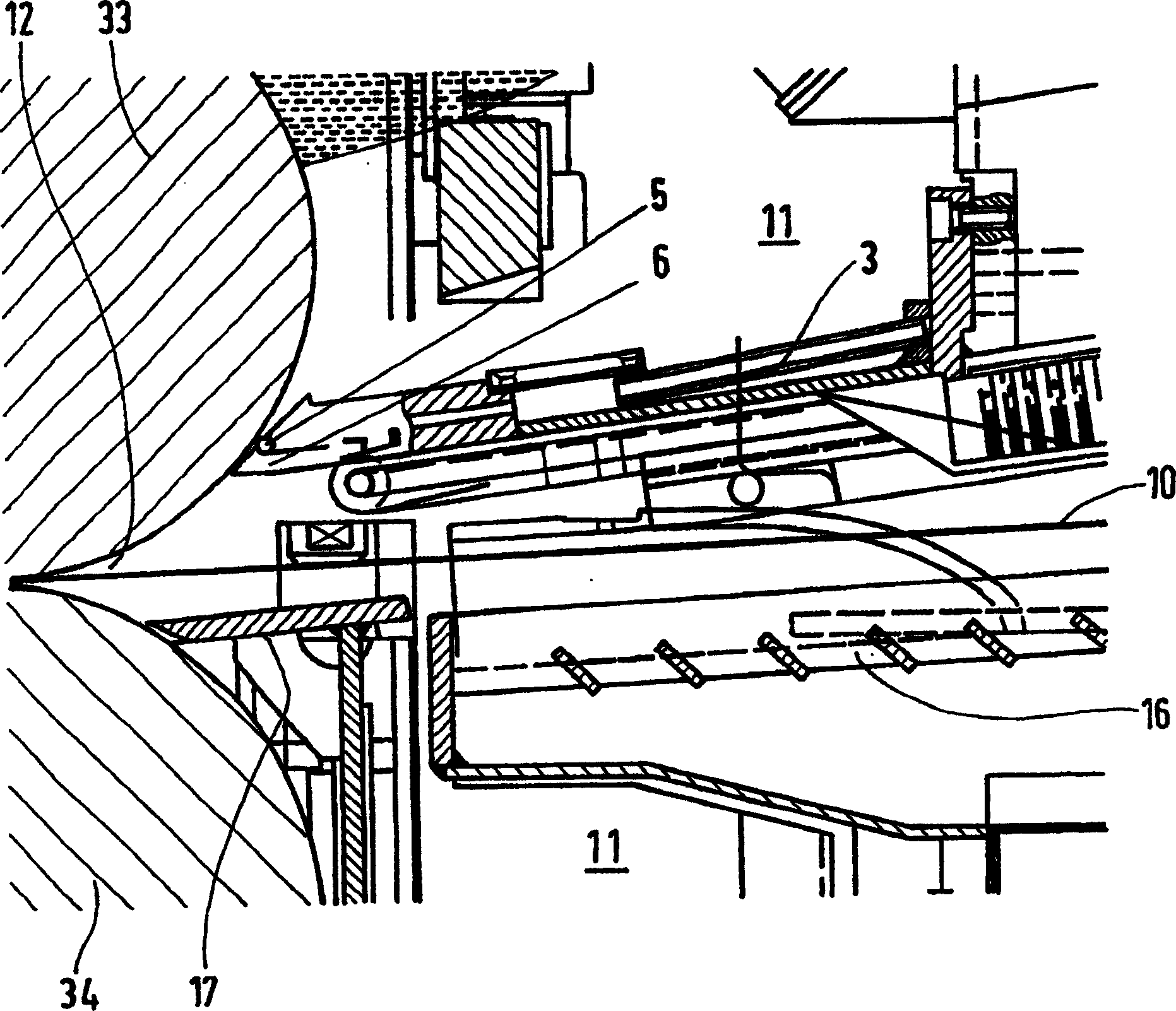

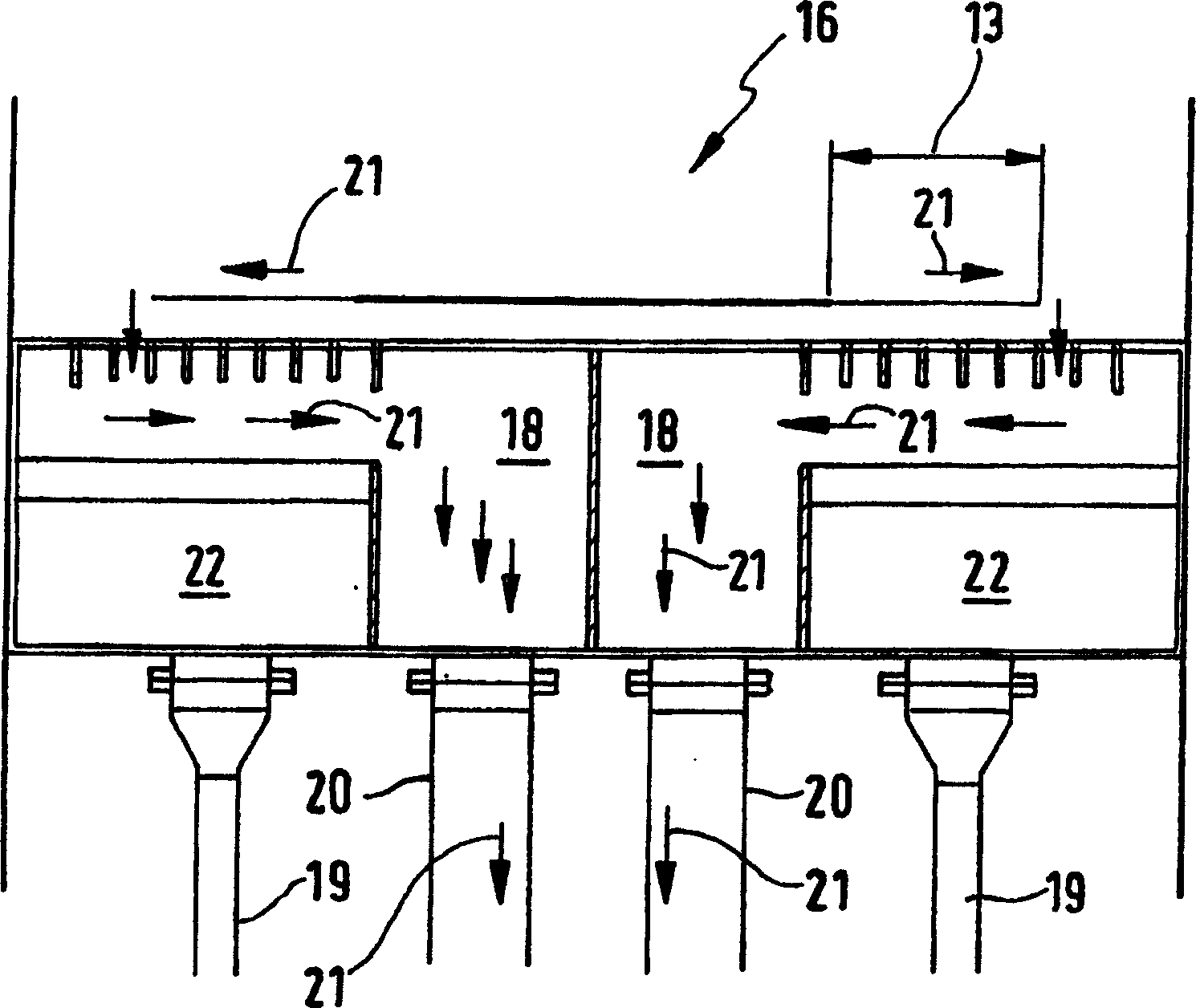

[0042] In the case of omitting the original rolling mill stand, figure 1 Shown are two backup rolls 31 , 32 and two work rolls 33 , 34 between the backup rolls, where the work roll gap 12 is adjustable. Above and below the rolled strip 10 coming out of the rolling mill (from left to right in the figure), there is a mist-filled rolling zone consisting of rolls 31, 32, 33, 34 and the rolled strip 10 11. The leaving rolled strip 10 should be shielded from the rolling area 11.

[0043] For this purpose, the mist-shrouded rolling zone 11 is already partially separated from the finished rolling strip 10 by a stationary upper guard device 1 and a permanently installed lower guard device 2 . The movable guard plate mechanism supplements the guard plate mechanisms 1 and 2 of the fixed installation.

[0044] Above the rolling strip 10 , this addition is a movably designed upper strip guide 3 , which includes a strip blowing device 4 driven by a fan and integrated with low-pressure noz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com