Light deflector and rear-projection screen

一种光偏转器、背面的技术,应用在仪器、光学、漫射元件等方向,能够解决图像鲜明度受损、光损失、双凸透镜片散射特性困难等问题,达到提高利用效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

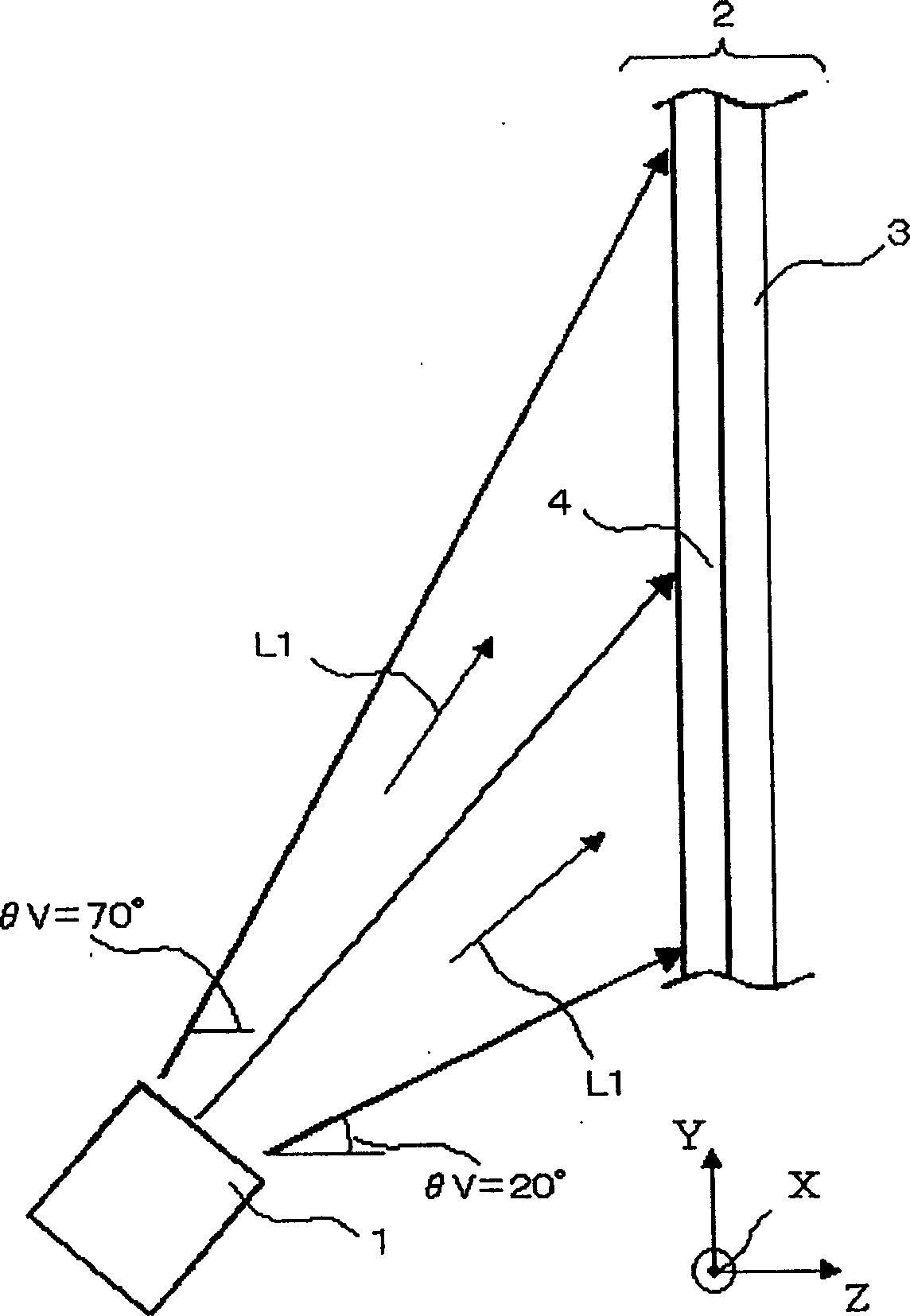

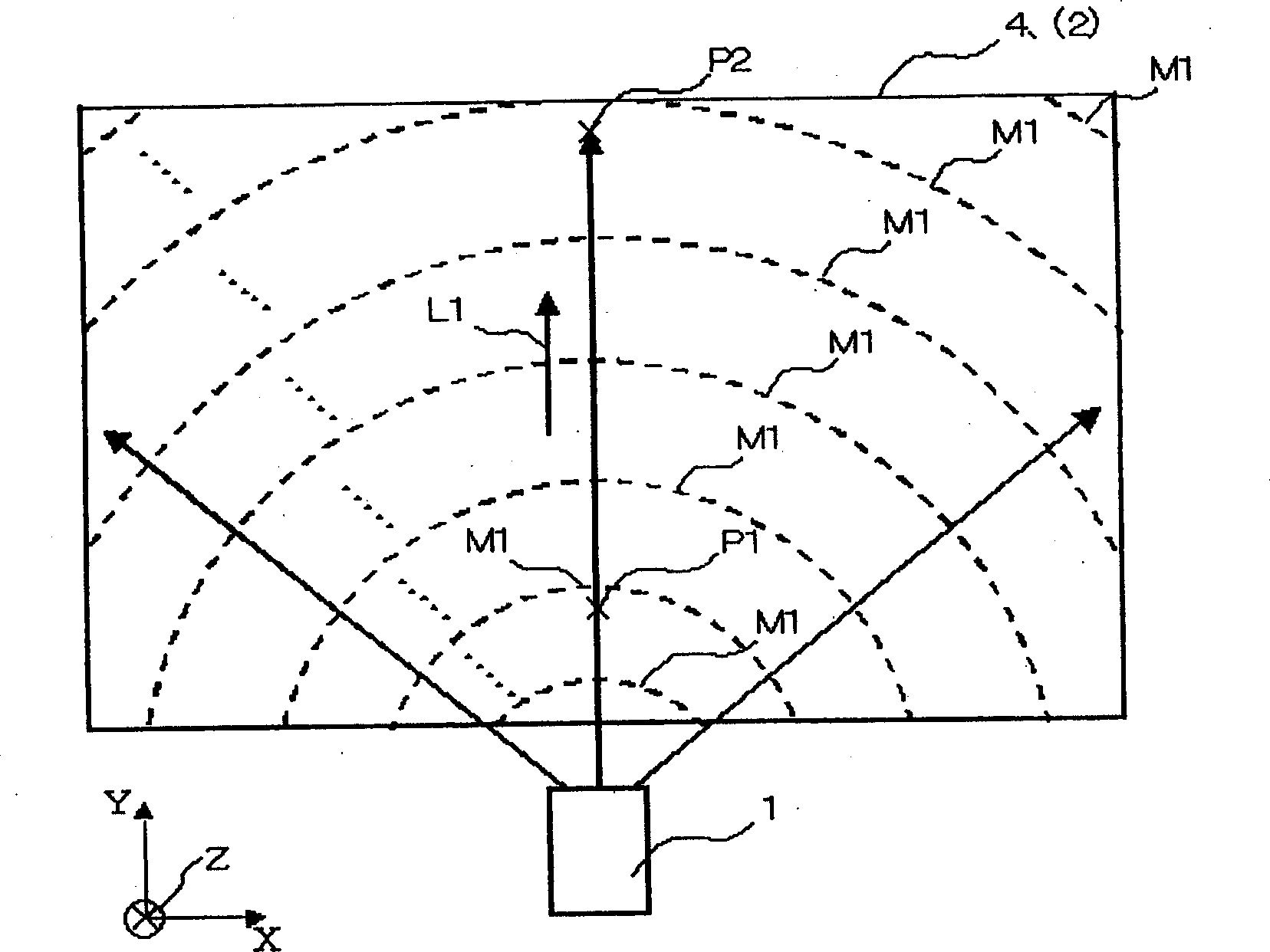

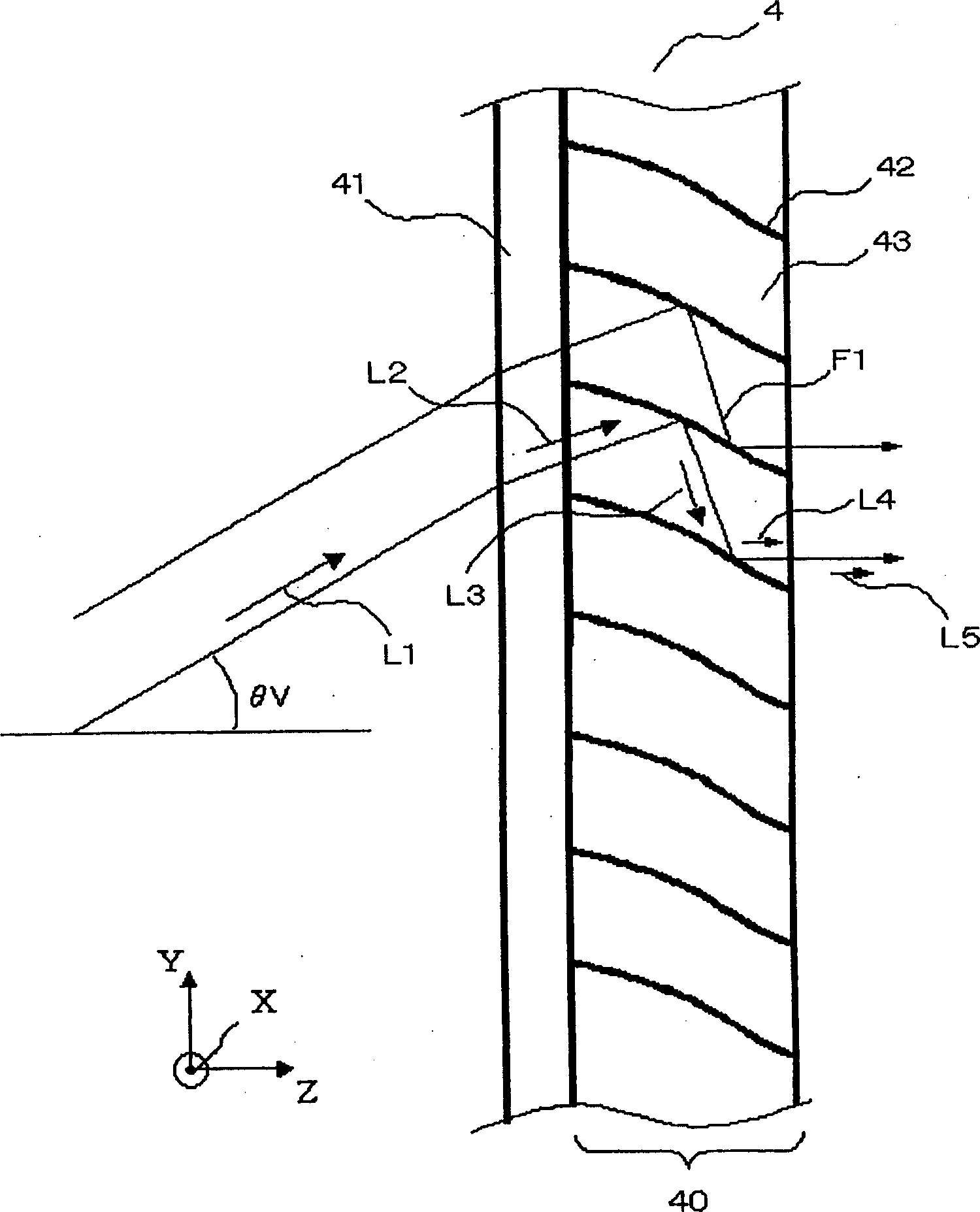

[0044] figure 1 It is a side view of the rear projection screen 2 in Embodiment 1. exist figure 1 Among them, the light projected from the light projection unit 1 (hereinafter referred to as projected light) is along the traveling direction of the light ( figure 1 While the L1) in is diffusing, it travels toward the rear projection screen 2. In this way, the image projected by the aforementioned light projection unit 1 is enlarged and projected onto the rear projection screen 2 . The rear projection screen 2 is composed of a light deflector 4 and a lenticular lens sheet 3 , and the light projected from the light projection unit 1 is first incident on the light deflector 4 . In addition, in the following description, the light incident on components such as the light deflector 4 and the lenticular lens sheet 3 constituting the rear projection screen 2 is called incident light, and the light emitted from the components is called outgoing light. In addition, the surface on wh...

Embodiment approach 2

[0074] Figure 6 It is a side view of the rear projection screen 22 in Embodiment 2. exist Figure 6 Among them, the projection light projected from the light projection unit 1 is along the traveling direction of the light ( Figure 6 L1) in ) diffuses and travels to the rear projection screen 22. In addition, in this embodiment, the same reference numerals are attached to the same configurations as those described in Embodiment 1 above, and description thereof will be omitted.

[0075] The rear projection screen 22 in Embodiment 2 is configured by bringing the first lens sheet 5 and the second lens sheet 6 close together and holding them with a projection screen holding frame (not shown) or the like.

[0076] The light projected from the light projection unit 1 first enters the second lens sheet 6 . The rear projection screen 22 imparts uniform directivity over the entire screen to the projection light projected from the light projection unit 1 onto the rear projection sc...

Embodiment approach 3

[0104] Figure 10 It is a side view of the case where the rear projection screen 23 in Embodiment 3 was seen from the X-axis direction. In this figure, the projection light projected from the light projection unit 1 travels to the rear projection screen 23 while being diffused along the traveling direction L1 of the light. Then, the aforementioned projection light reaches the rear projection screen 23 , so that the image projected by the aforementioned light projection unit 1 is enlarged and projected onto the rear projection screen 23 . The rear projection screen 23 in this embodiment is configured such that the first lens sheet 7 , the second lens sheet 8 , and the Fresnel lens sheet 9 are brought close to each other and integrally held. In addition, the aforementioned Fresnel lens sheet 9 is a lens sheet having a light-gathering ability of 0 (zero), and is provided on the incident surface of the rear projection screen 23 .

[0105] Figure 11 It is an explanatory diagram...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com