Soft-body packaging bag

A soft packaging bag, a new type of technology, applied in the field of liquid packaging bags, can solve the problems of high cost, poor rigidity, and difficult to place, and achieve the effects of low cost, improved rigidity, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

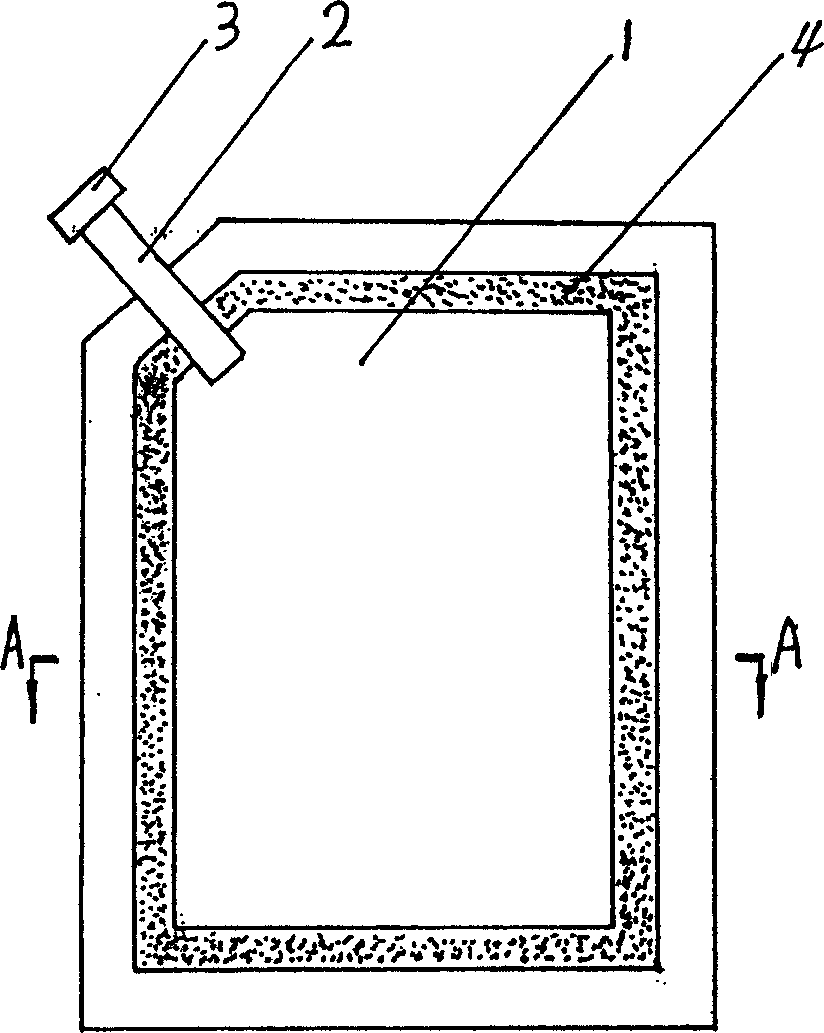

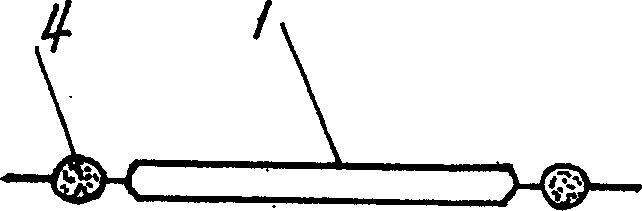

[0018] Example 1: figure 1 and figure 2 The structure diagram of this embodiment is given, which is composed of a bag body 1 and a bag spout 2, and the bag spout 2 is installed on the upper left corner of the upper end of the bag body 1 to facilitate pouring of liquid. The bag mouth 2 is provided with a cover 3, and the filling cavity 4 is arranged on the periphery of the bag body 1, and is filled with air, foam, rubber, plastic, plant fiber or industrial fiber.

Embodiment 2

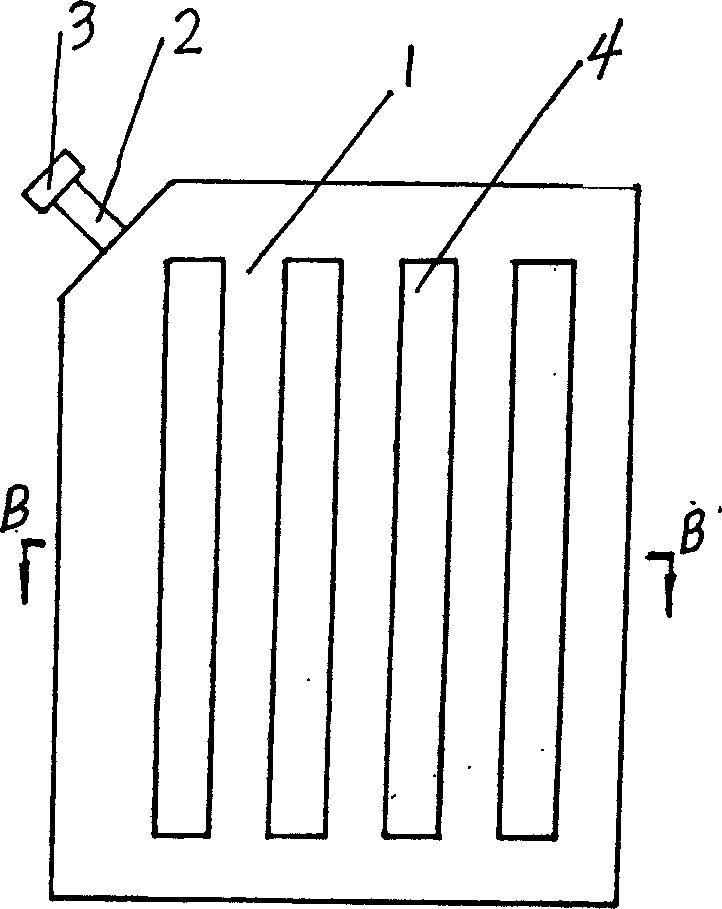

[0019] Example 2: image 3 and Figure 4 A schematic structural diagram of this embodiment is given. The difference from Embodiment 1 is that the filling cavity 4 is arranged on the front and back sides of the bag body in a vertical strip shape.

Embodiment 3

[0020] Example 3: Figure 5 and Image 6 A schematic structural diagram of this embodiment is given. The difference from Embodiment 1 is that the filling cavity 4 is arranged inside the bag body 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com