Apparatus for separating gas into gas components using ionization

A gas component and equipment technology, applied in the field of equipment that uses ionization to separate gas into several gas components, can solve the problem that the separation efficiency depends on the state of pressure or temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

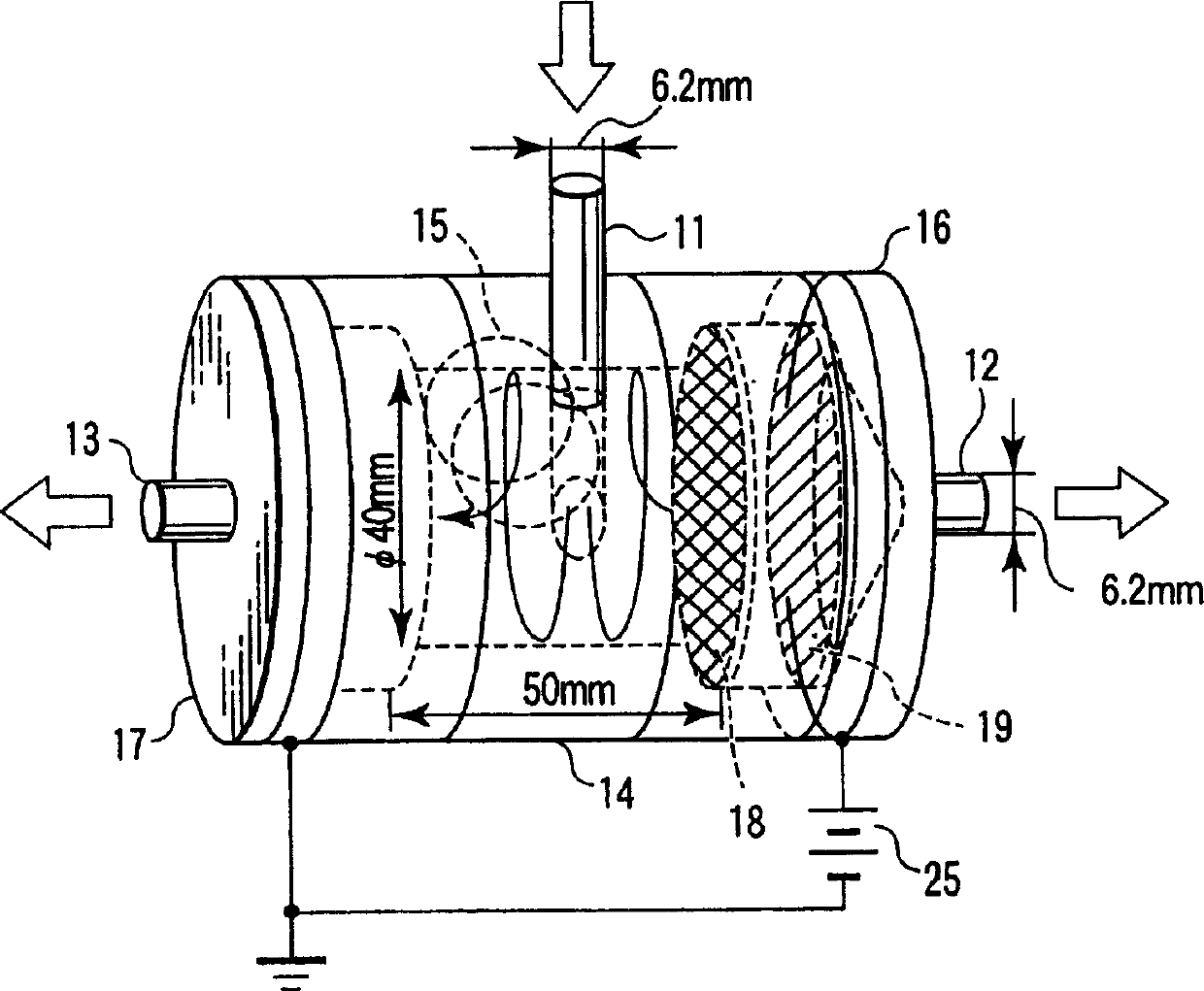

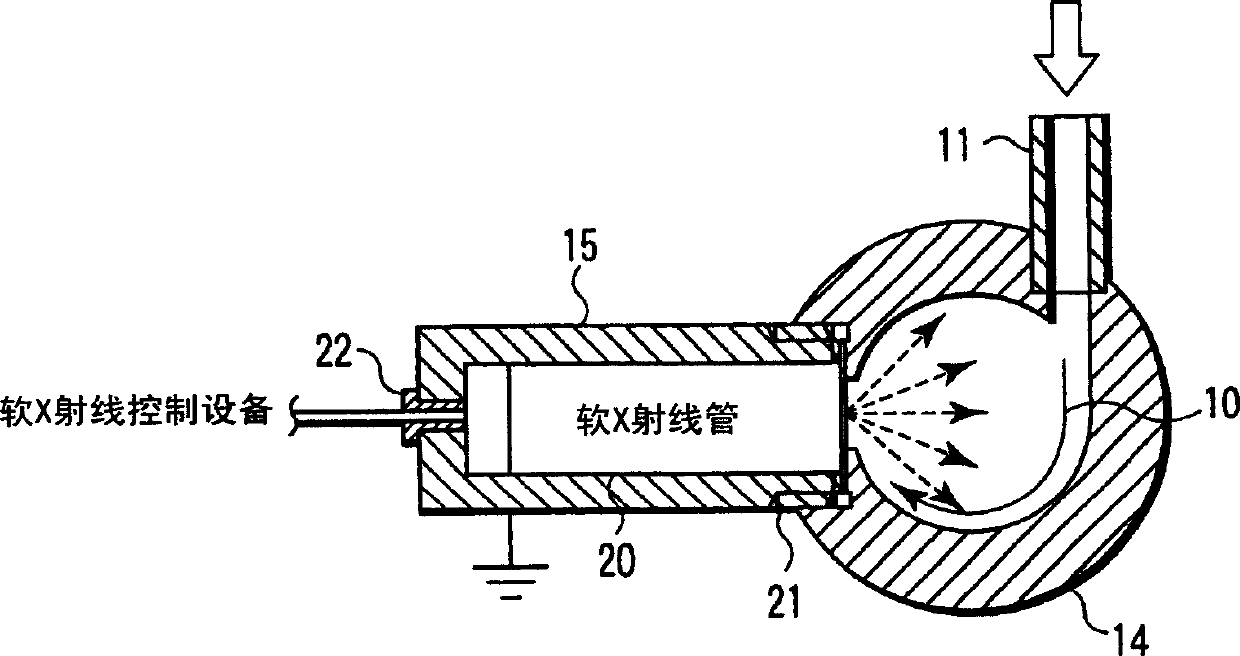

[0029] A gas ionization / separation device according to an embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

[0030] Fig. 1 shows a double-branch gas ionization / separation device according to an embodiment of the present invention. In this gas ionization / separation apparatus, an ion generation process and an ion separation process using an electric field are simultaneously performed, and an electrode for applying the electric field has a configuration serving as a gas discharge port. In Fig. 1, reference numeral 11 refers to the inlet of the gas mixture, such as the inlet of the mixture of air and gas, through which the gas mixture flows into the device, and 12, 13 refer to the gas outlet , through which the separated gas components flow out, and 14 designates a separation chamber in which a flow channel is defined. In the separation chamber 14, an ionizer 15 is provided to ionize the gas components in the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com