Manufacturing process of untwisted yarn

A manufacturing method and technology of twisting silk, applied in textiles, papermaking, yarn, etc., can solve the problems of environmental pollution, human harm, and it takes a long time to dissolve soluble silk, and achieve the effect of excellent stretchability and tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

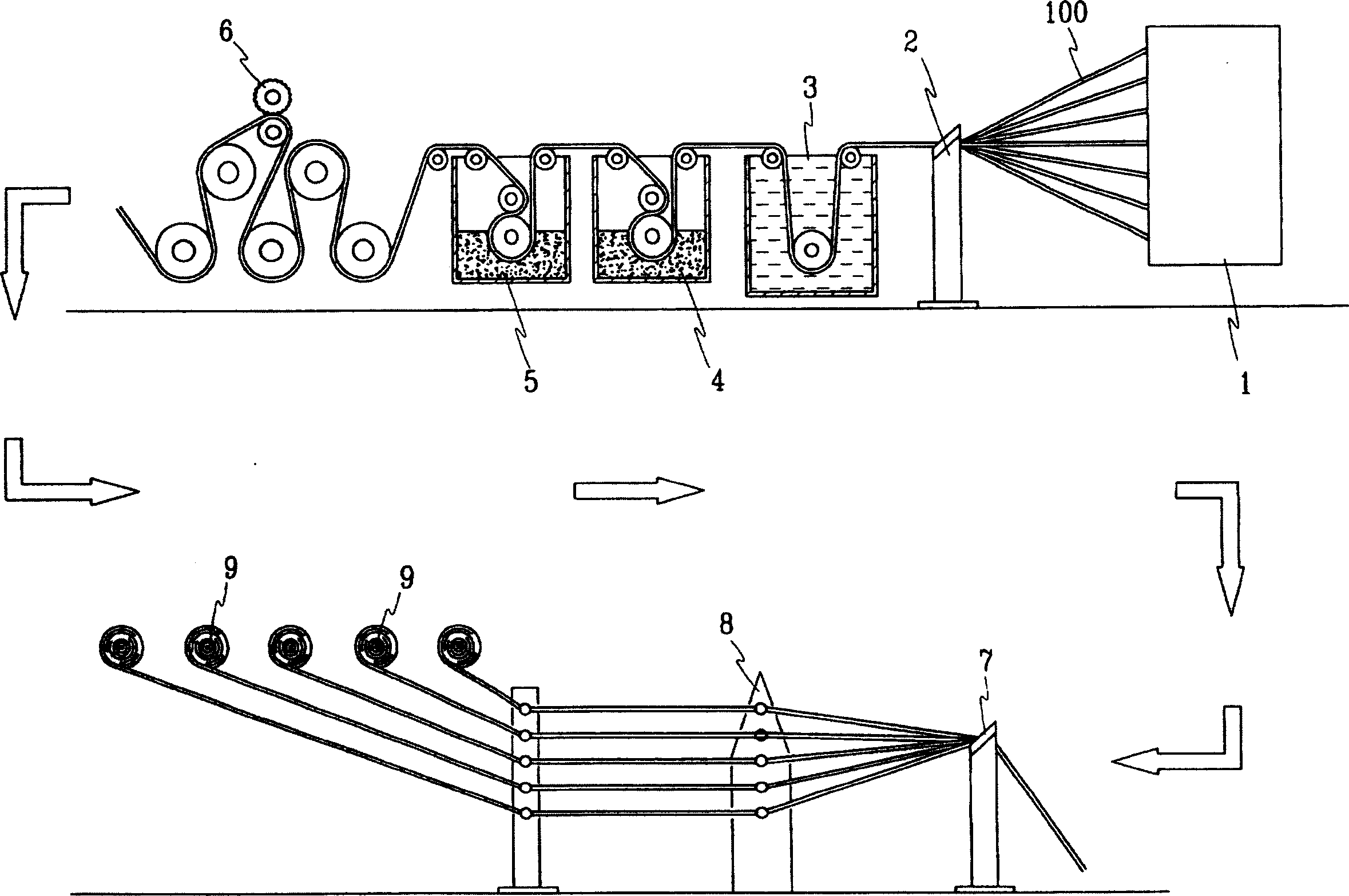

[0019] Below in conjunction with accompanying drawing, the manufacturing method of untwisted yarn of the present invention is described in detail according to its procedure.

[0020] ①Steam supply process

[0021] Such as figure 1 As shown, firstly, the spun yarn 100 (cotton yarn, wool yarn, staple fiber yarn, etc.) is supplied to the steam supply device 3 from a creel 1 and a reed 2 .

[0022] The steam supply device 3 is provided with an internal space capable of receiving steam, so that the spinning reed 2 absorbs a certain amount of water when passing through the internal space. Here, the reason for allowing the spinning to absorb moisture is that the spinning with a certain amount of moisture is more likely to saturate the paste than the spinning that is completely dry. That is, the steam supply step of the present invention is provided before the sizing step, so as to improve the adhesiveness of the spinning when sizing.

[0023] ②Sizing process

[0024] This step is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com