Valve operating device for internal combustion engine

A transmission device, internal combustion engine technology, applied in the direction of internal combustion piston engine, valve device, combustion engine, etc., can solve the problems of reduced thermal efficiency, reduced output power, increased exhaust loss of combustion gas, etc., to prevent and suppress intake air blowback. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

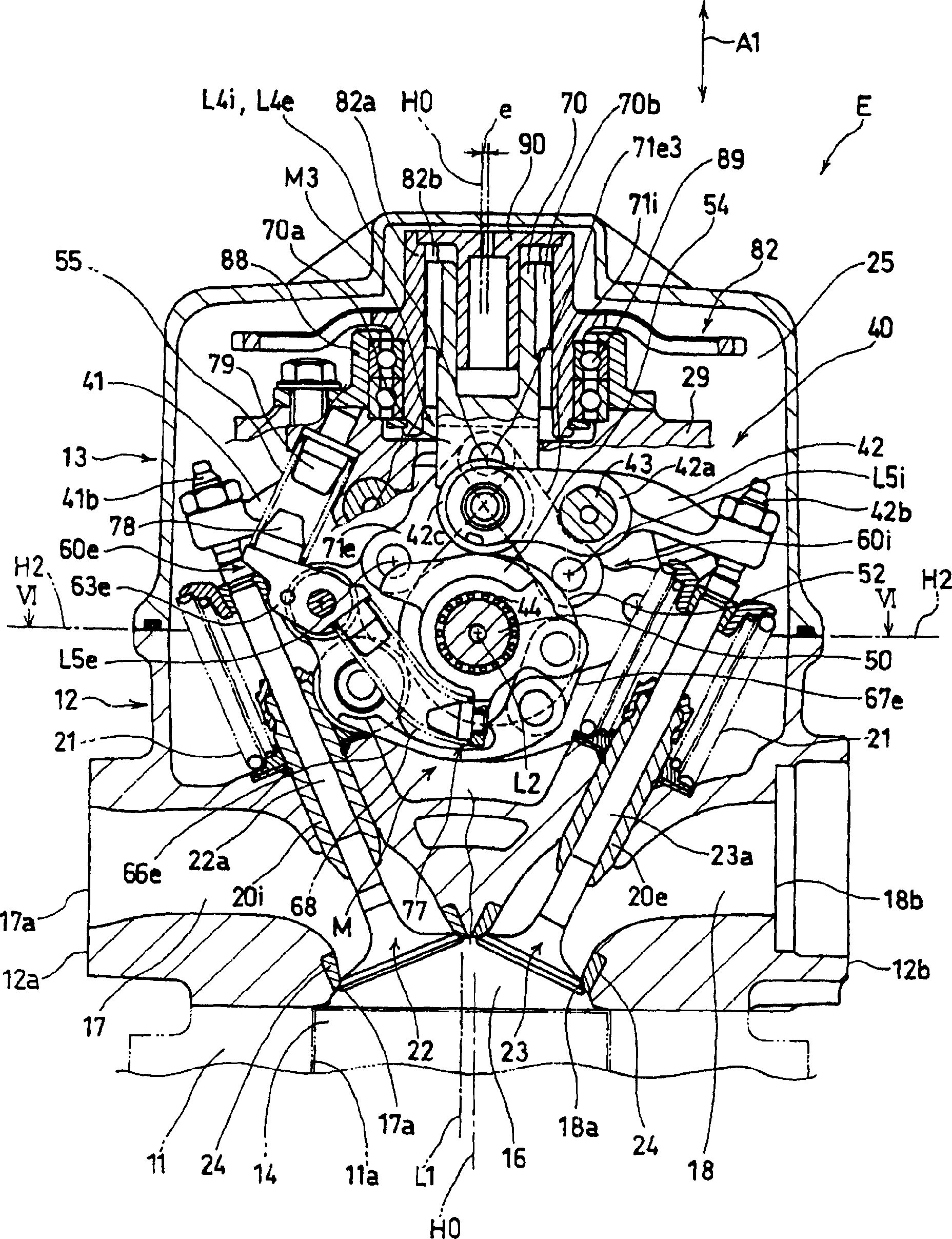

[0066] Below, refer to Figure 1 to Figure 14 Embodiments of the present invention will be described.

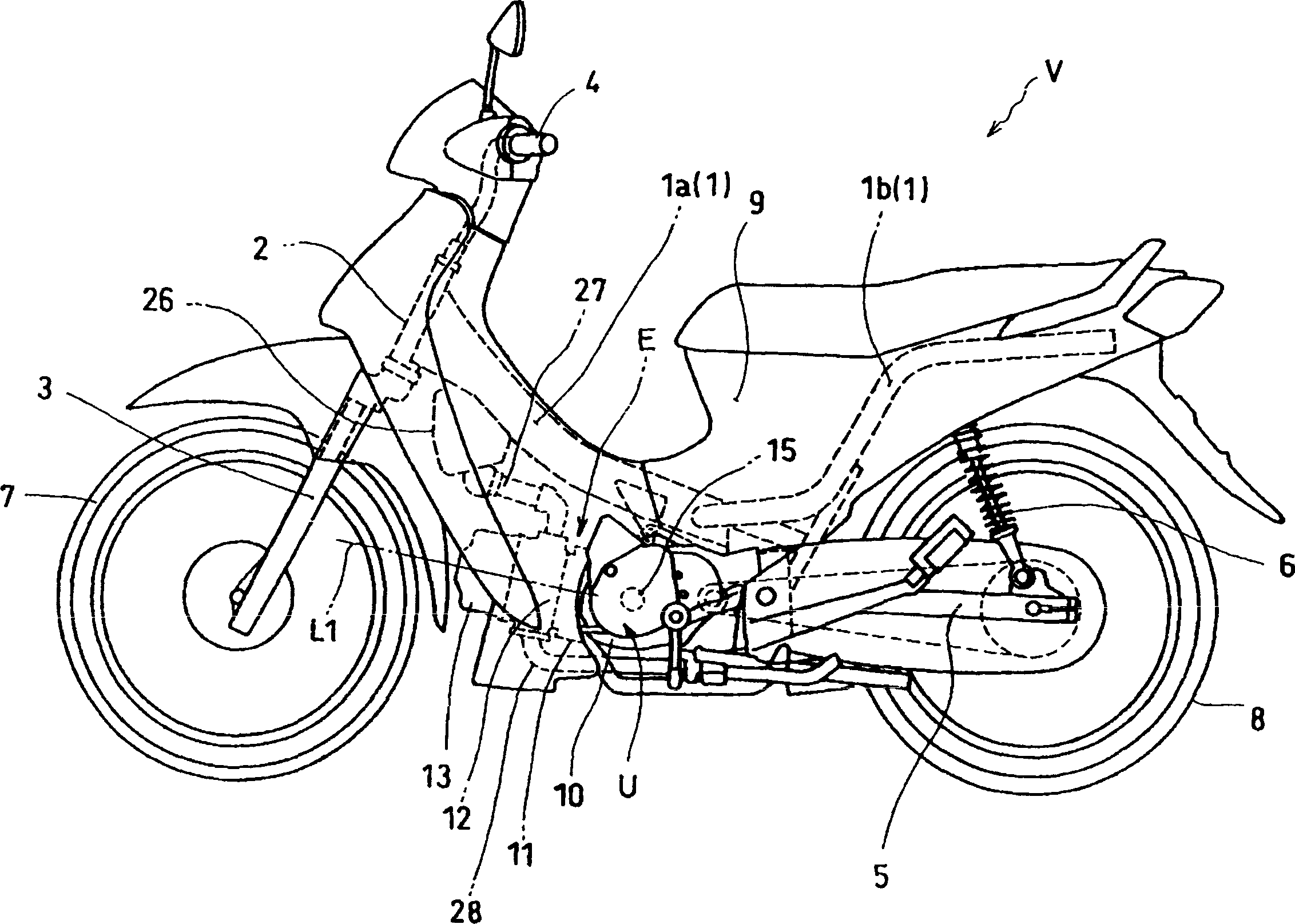

[0067] see figure 1 , the internal combustion engine E to which the present invention is applied is mounted on a vehicle, a two-wheeled motor vehicle V. The two-wheeled vehicle V has: a vehicle frame 1 including a front frame 1a and a rear frame 1b; a handle 4 fixed to the upper end of a front fork 3 rotatably supported on a front main pipe 2 connected to the front frame 1a ; the front wheel 7 rotatably supported on the lower end of the front fork 3 ; the power unit U supported on the vehicle frame 1 ; the rear wheel 8 rotatably supported on the rear end of the swing arm 5 , which can swing The rear shock absorber 6 connecting the rear part of the rear frame 1b and the swing arm 5; the vehicle body cover 9 surrounding the vehicle frame 1.

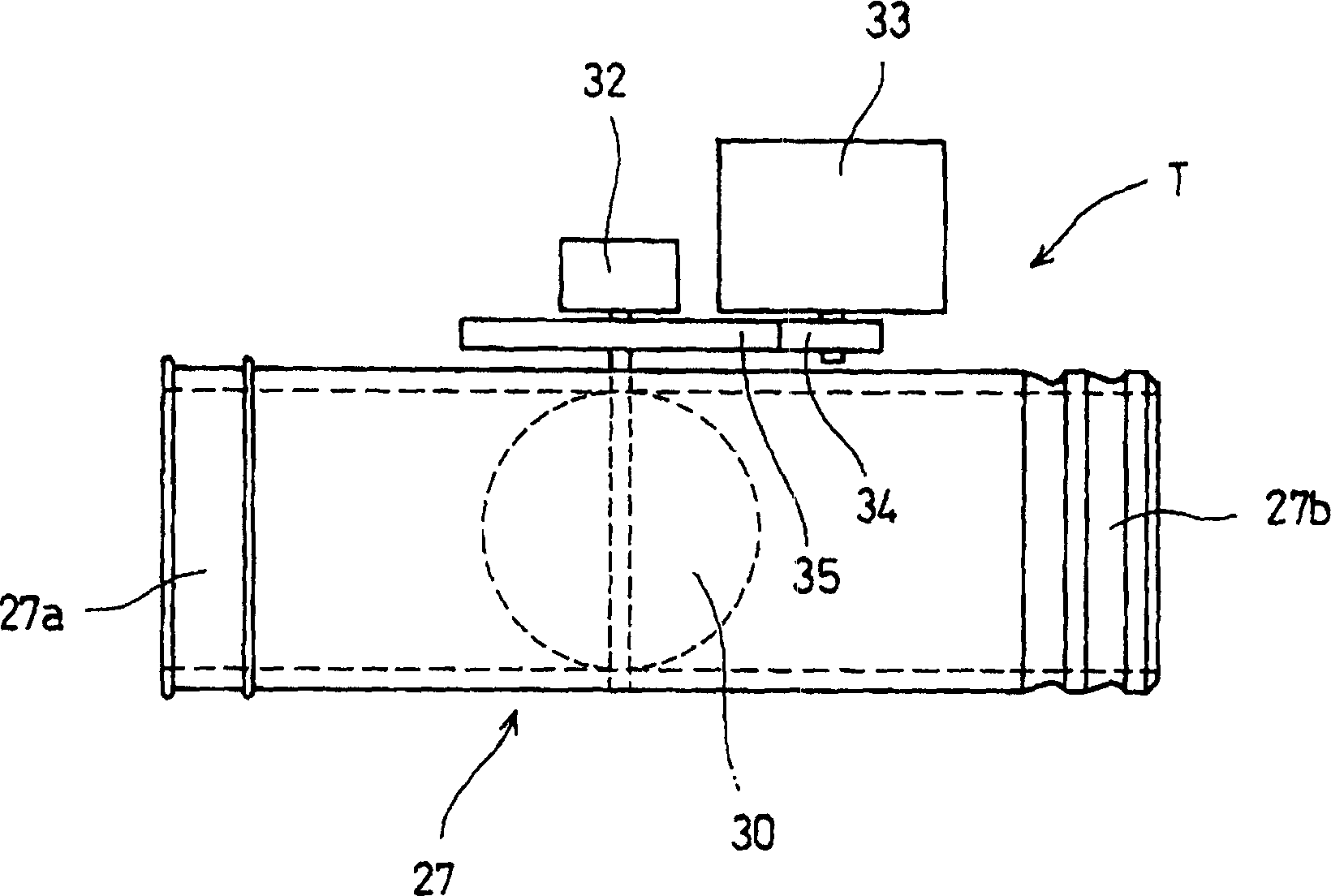

[0068] The power unit U includes: a transverse internal combustion engine E having a crankshaft 15 extending in the left-right direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com