Refined polycarbonic ester organic solution and process for preparing high purity polycarbonic ester

A technology of polycarbonate and organic solution, applied in the field of manufacturing high-purity polycarbonate, can solve problems such as no record in the present invention, no disclosure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

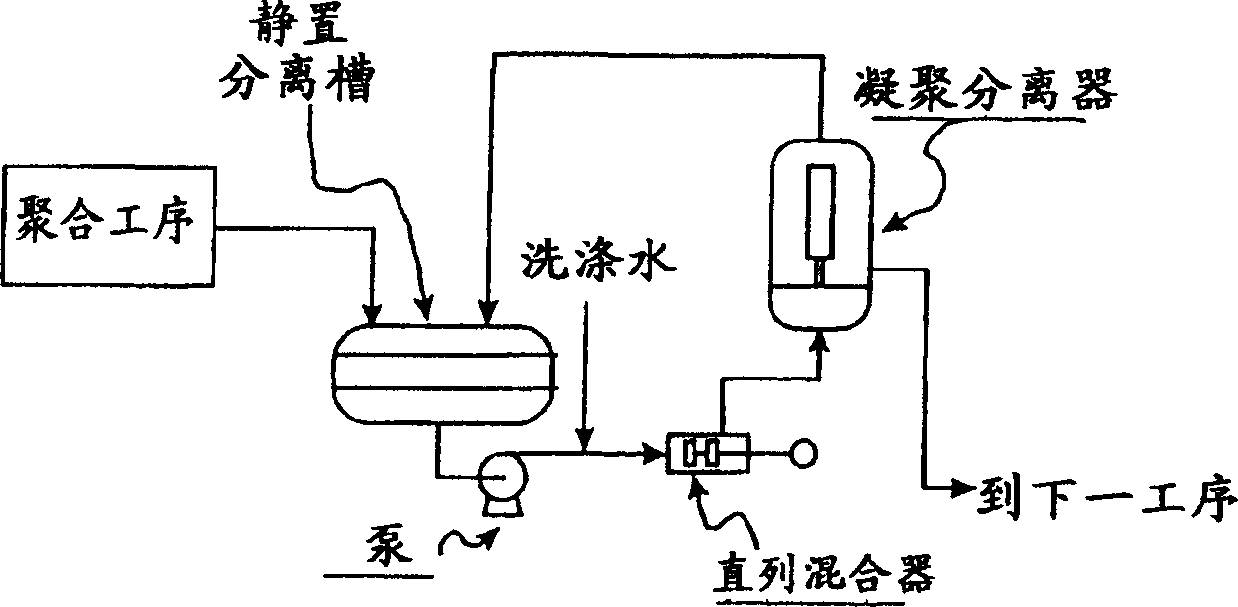

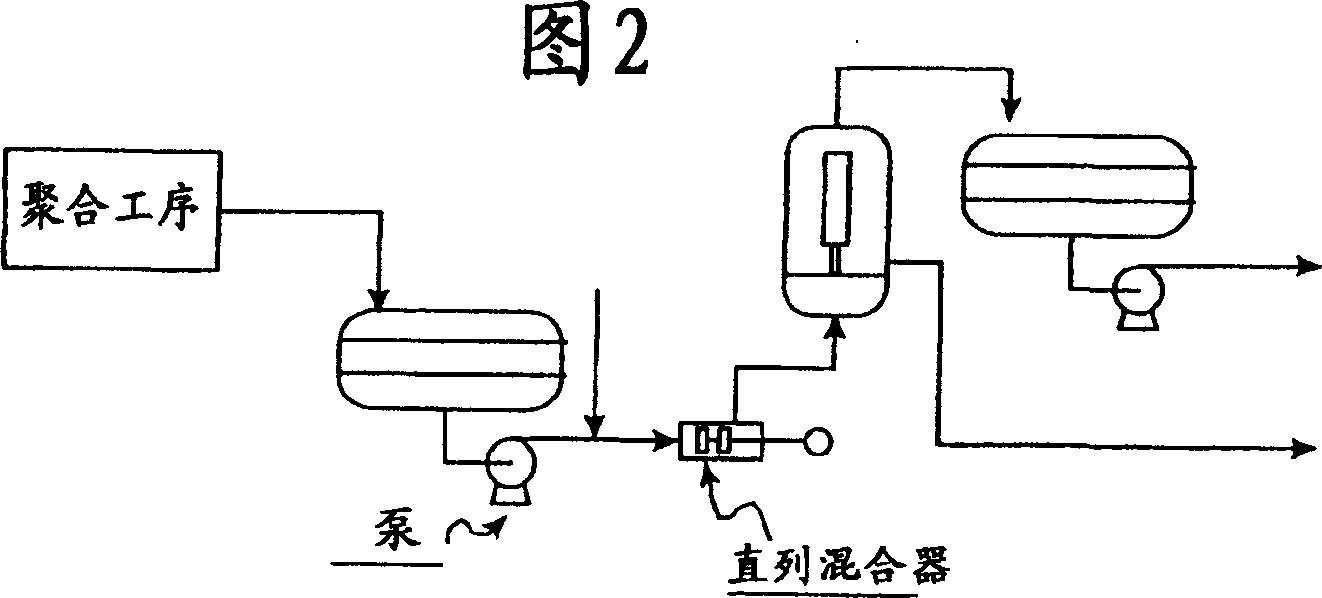

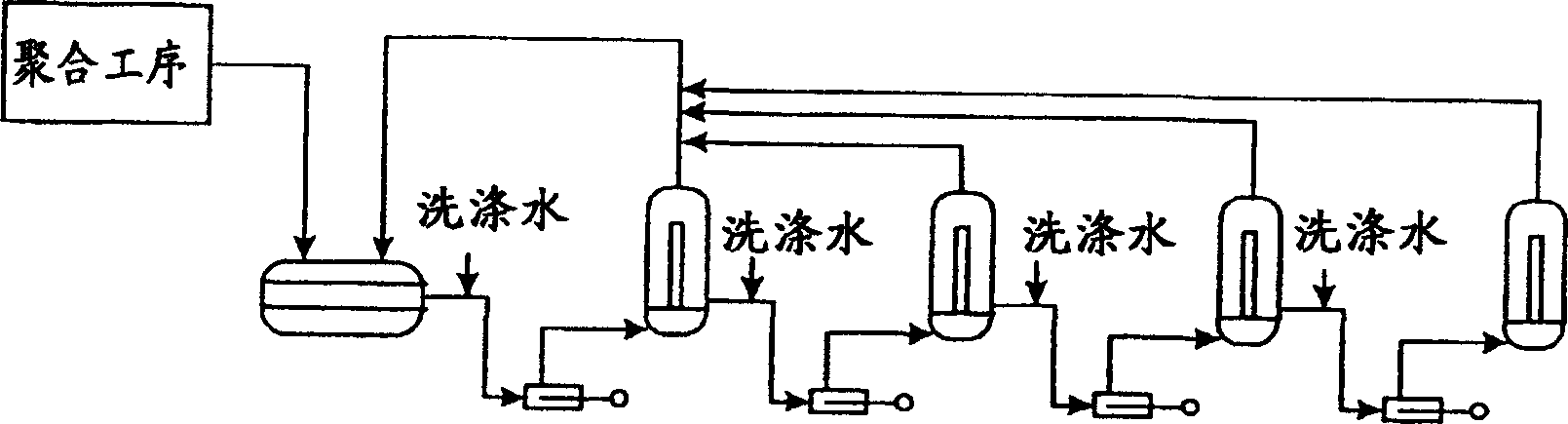

Method used

Image

Examples

manufacture example 1

[0079] (1) Manufacture of polycarbonate oligomers

[0080] Bisphenol A (BPA) was dissolved in a caustic soda (NaOH) aqueous solution having a concentration of 6% by mass to obtain a BPA-NaOH solution having a concentration of 14.5% by mass. The obtained BPA-NaOH solution was mixed at 40 L / hr, the p-tert-butylphenol (PTBP: molecular weight modifier)-dichloromethane solution with a concentration of 25% by mass at 0.35 L / hr, and the solvent dichloromethane at 18.5 L / hr. The flow rate was immersed in a cooling tank at 20° C., introduced into a tubular reactor with an inner diameter of 6 mm and a length of 30 m, and then blown into phosgene at a flow rate of 3.8 kg / hr. The reaction mixture from the reactor was introduced into a separation tank, and the aqueous phase was separated to obtain an organic phase containing a dichloromethane solution of polycarbonate oligomers.

[0081] The properties of the obtained polycarbonate oligomer were analyzed and the results are shown below. ...

Embodiment 1

[0087]Dichloromethane was added to the reaction mixture containing polycarbonate obtained according to the above-mentioned Production Example 1, and the polycarbonate concentration of the polycarbonate solution on the organic phase side was adjusted to 12% by mass. Dichloromethane solution of polycarbonate (organic phase) and aqueous phase. The water content in the separated organic phase was measured and found to be 7500 ppm by mass. In addition, when the crude polycarbonate before adding dichloromethane was measured by another method to measure the viscosity average molecular weight of the polymer, MV=28700, when analyzing the water phase side, BPA was dissolved at a concentration of 21g / L, and the NaOH concentration was 0.22mol / L.

[0088] The dichloromethane solution (organic phase) containing polycarbonate obtained in this way was mixed at 600 L / hr, and the caustic soda aqueous solution of pH=13 modulated with NaOH was used at 60 L / hr with an in-line mixer (manufactured...

Embodiment 2~11

[0091] Except for changing the flow rate of the polymer solution, the supply amount of the aqueous cleaning solution, the stirring power, and the material of the parts in the coagulation separator as described in Table 1 below, the implementation was carried out according to Example 1. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com