Umbrella structure constant force spring hanging frame

A constant force spring and hanger technology, applied in the direction of pipeline supports, pipes/pipe joints/pipes, mechanical equipment, etc., can solve the problems of large horizontal space occupation, product standardization, low degree of serialization, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

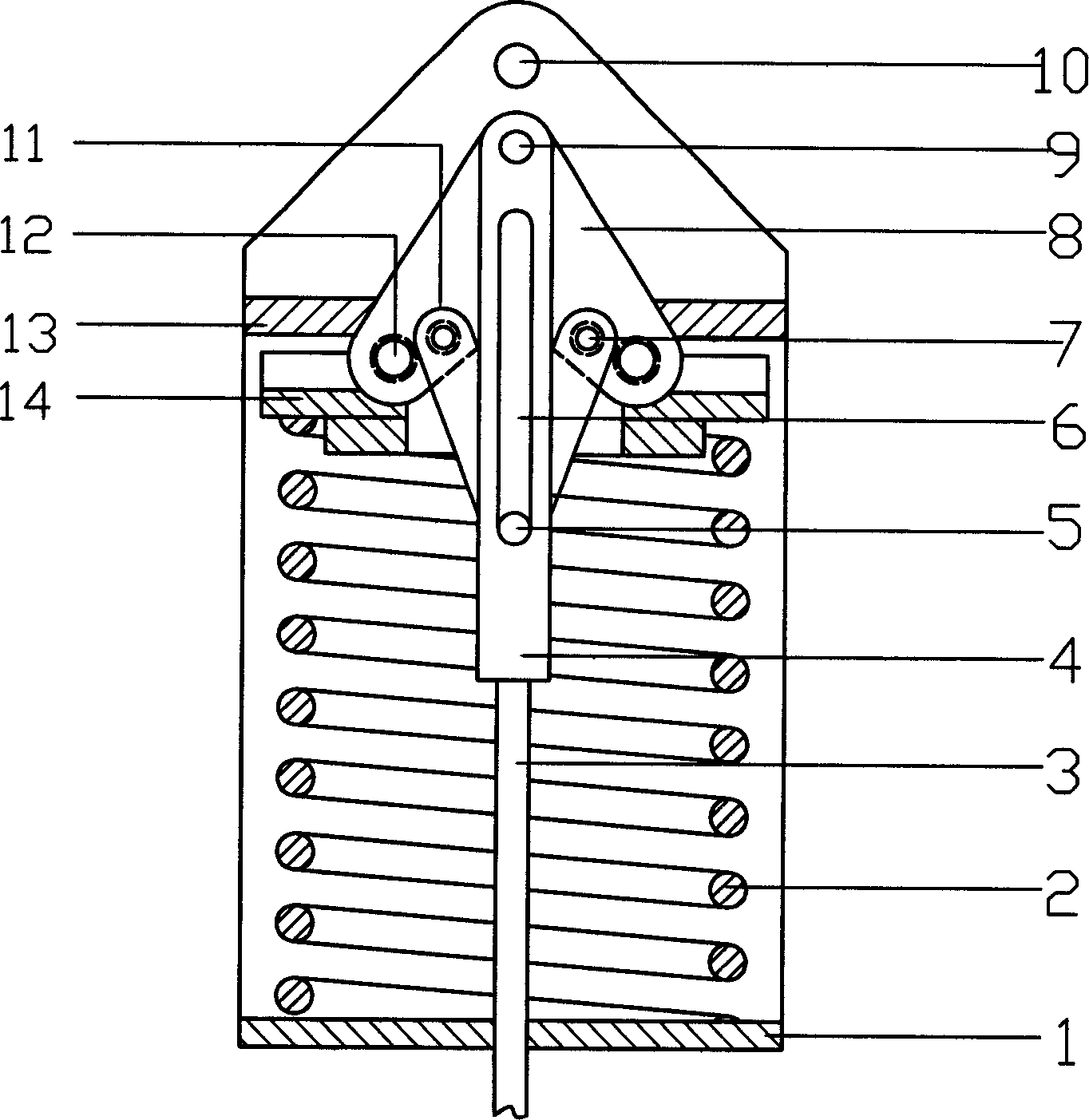

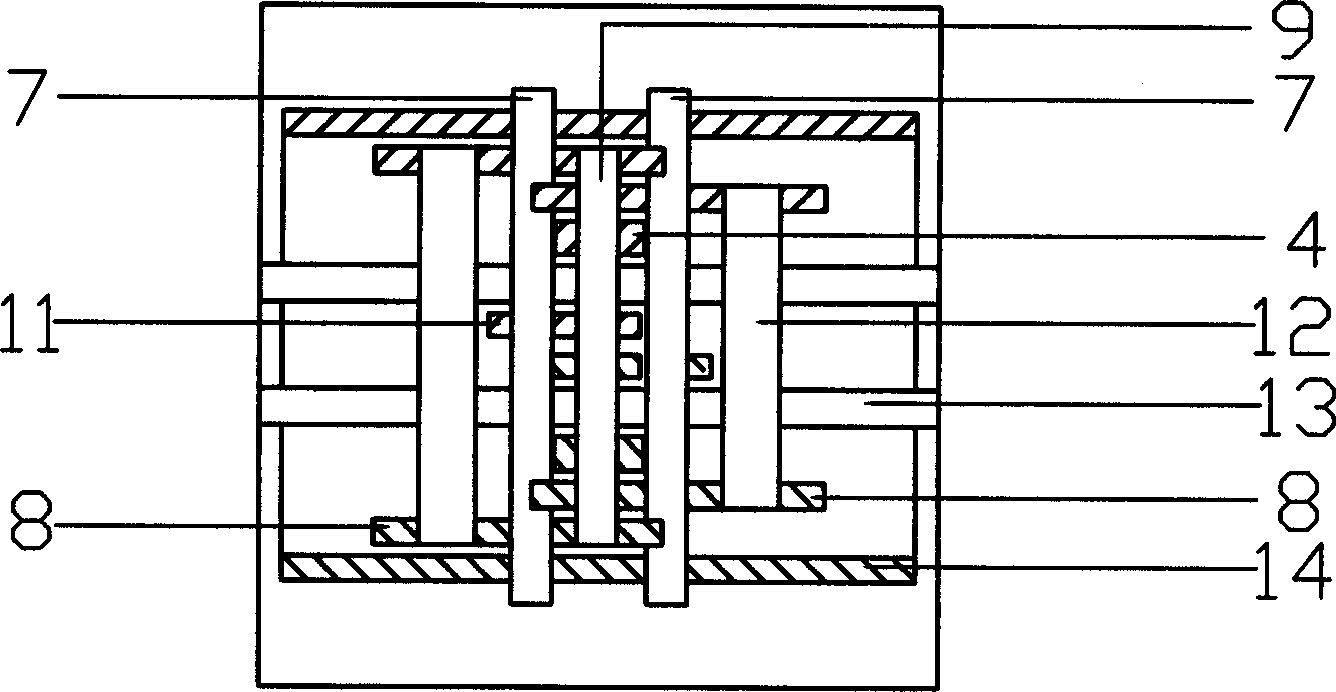

[0017] Working principle: when the load rod 3 bears the downward pulling force, the final shaft 7 bears the downward force, and the main shaft 12 bears the upward force. As the displacement of the load rod 3 changes, the spring 2 is under the action of the final shaft 7 and the pressure plate 14 When the elastic force changes, the center distance between the load rod 3, the final shaft 7 and the final shaft 7, and the main shaft 12 also changes correspondingly at the same time, so as to achieve the effect of moment balance.

[0018] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings:

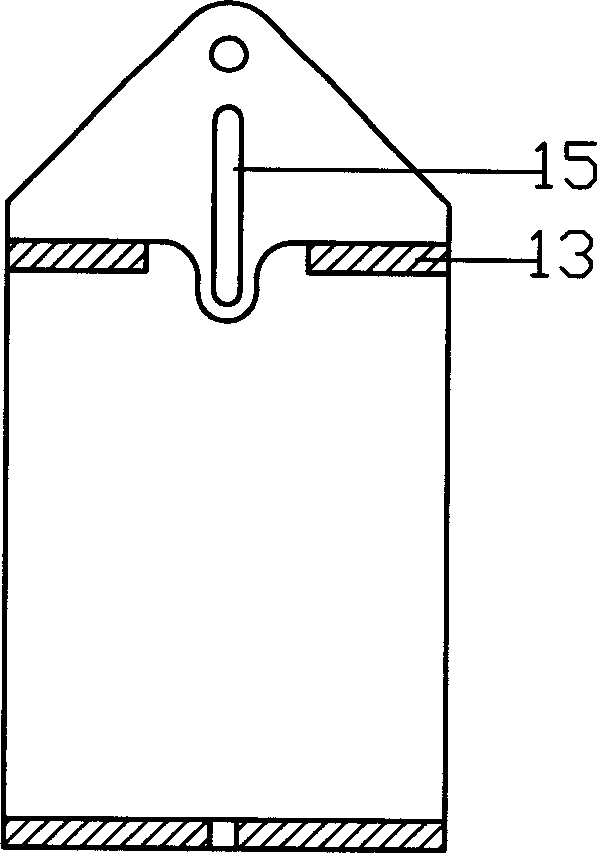

[0019] image 3 It is an overall view of the fixed frame 13 and the housing 1. There is a hole for the boom shaft 10 at the center of the upper part of the fixed frame 13. Below the center line of the hole is the load shaft slideway 15. There is a plane on both sides of the load shaft slideway 15. The main shaft 12 performs a horiz...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com