Thermal transfer element

一种热转移、元件的技术,应用在电气元件、电固体器件、半导体器件等方向,能够解决产量降低、厚度不规则等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

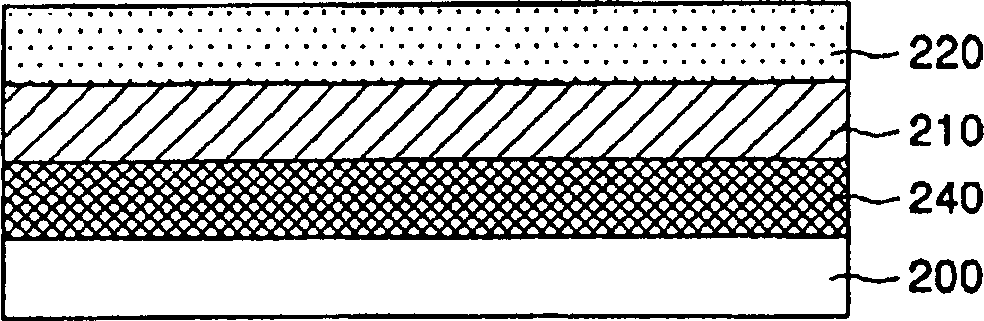

[0026] figure 2 is a cross-sectional view of a laser thermal transfer element for forming an organic thin film layer of an OLED according to a first embodiment of the present invention;

[0027] refer to figure 2 , The laser thermal transfer element according to the first embodiment of the present invention includes a base substrate 200 , a light-to-heat conversion (LTHC) layer 210 , and a transfer layer 220 . The base substrate 200 serves as a supporting substrate for supporting the laser thermal transfer element. The base substrate 200 is made of a transparent polymer such as polyester, polypropylene, polyepoxy, polyethylene, polystyrene, polyethylene terephthalate, etc., and has a thickness of about 10-500Φm. The base substrate 200 may employ a substrate such as a glass substrate or a thin film.

[0028] The LTHC layer 210 absorbs light to convert light into thermal energy, and it has a suitable optical density and includes a light absorbing material. The light-absorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com