System and method for inspecting a beam using micro fiber-optic technology

A fiber-optic, miniature technology, applied to inspect the hidden surface in the beam, inspect the surface of the beam, and can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Although the preferred embodiment is described below with regard to inspecting the floor beams of an aircraft, the invention should not be so narrowly understood or restricted to use only on aircraft. It is contemplated that the present invention is applicable to inspecting the concealed surface of any beam, whether in an aircraft, bus, ship, building or any other structure.

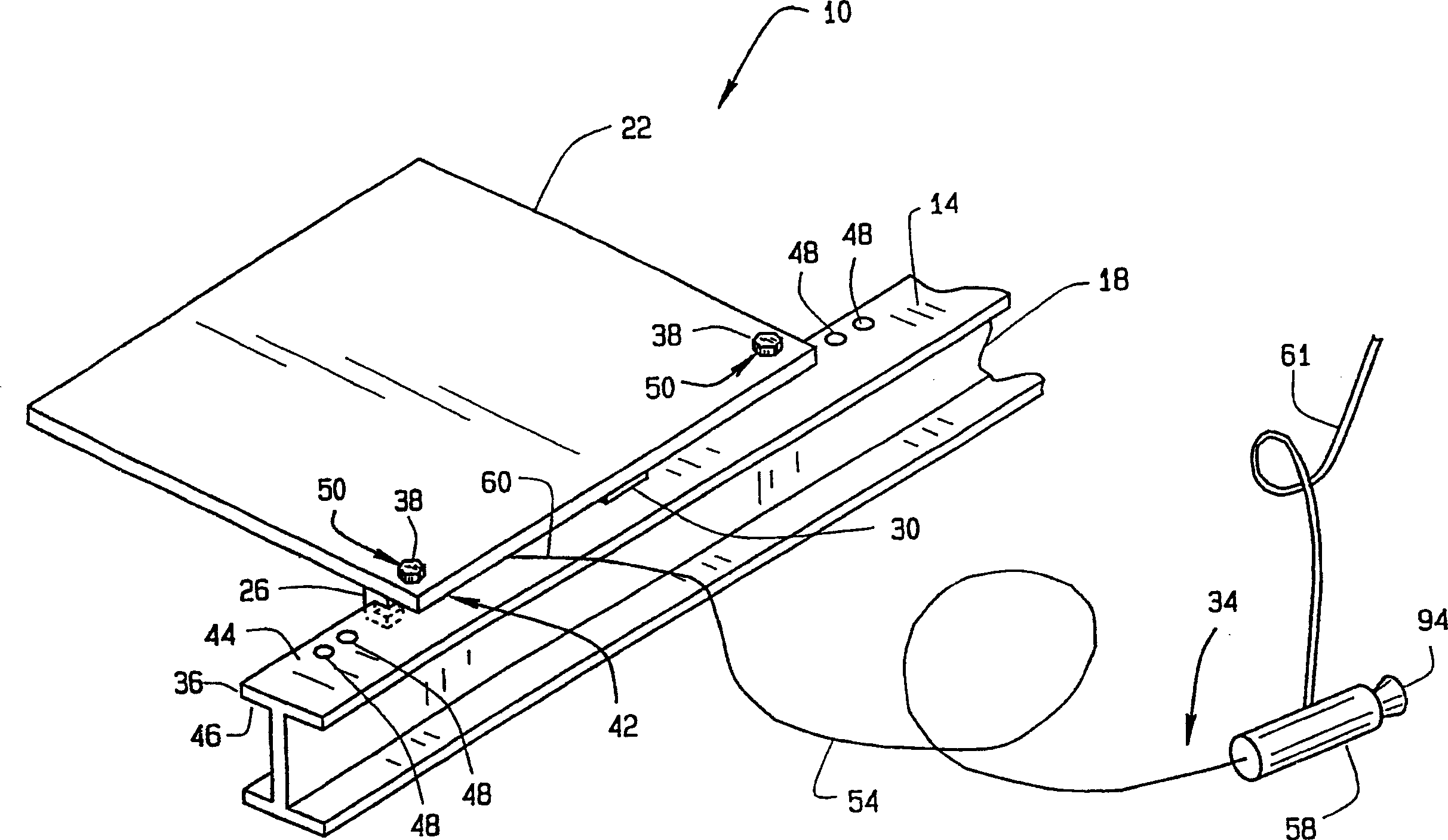

[0015] figure 1 is a perspective view of a system 10 for inspecting the upper surface 14 of a floor beam 18 covered by a floor panel 22 in accordance with a preferred embodiment of the present invention. The term "floor beam" is intended to include any beam or member used to support the floor panel 22, for example, in aircraft terms the term "floor beam" includes aircraft seat rails.

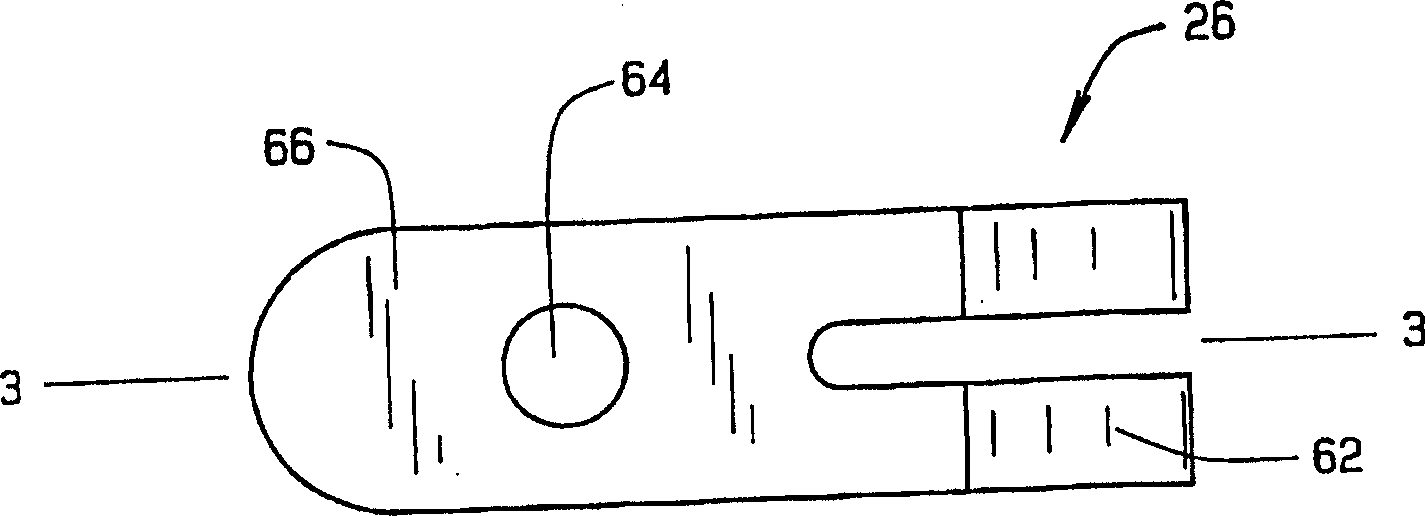

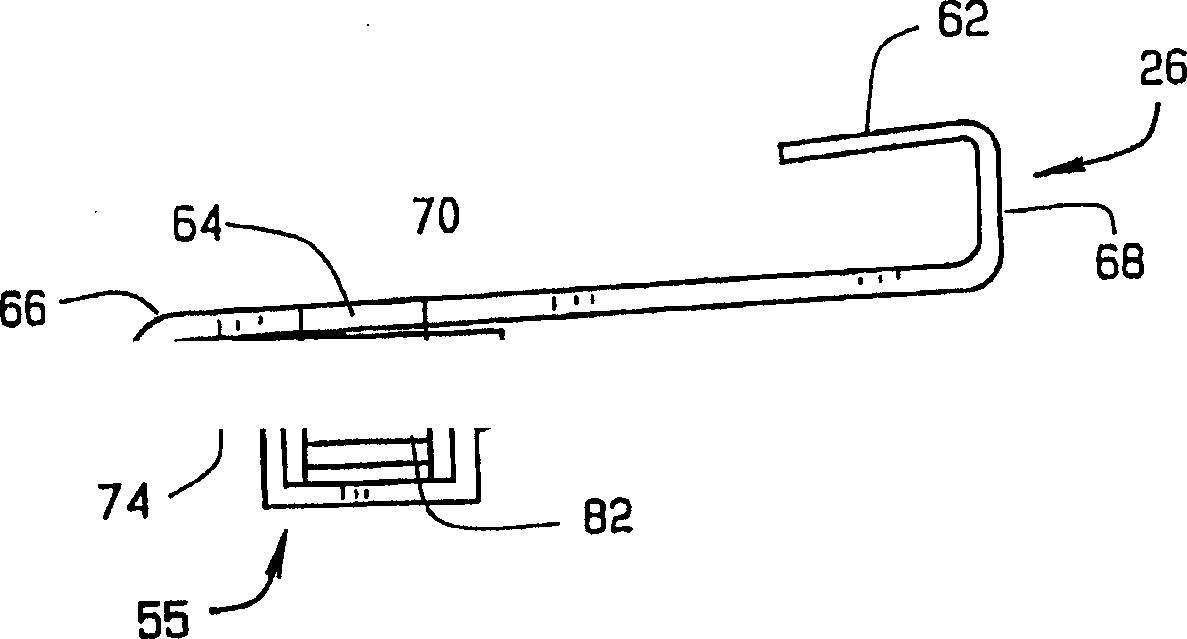

[0016] The inspection system 10 includes at least one nut clamp 26 , at least one spacer 30 and a miniature fiber optic borescope 34 . The nut clips 26 are mounted to the floor rail flanges 36 and the floor panels...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap