Inhalable particulates removing tower with non-motile finned tubes

A removal tower, passive technology, applied in the field of industrial dust removal equipment, can solve problems such as being difficult to apply to engineering practice, and achieve the effects of improving thermophoretic deposition efficiency, reducing tube wall temperature, and increasing particle deposition area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The specific structure, working process and best implementation mode of the present invention will be further described below in conjunction with the accompanying drawings.

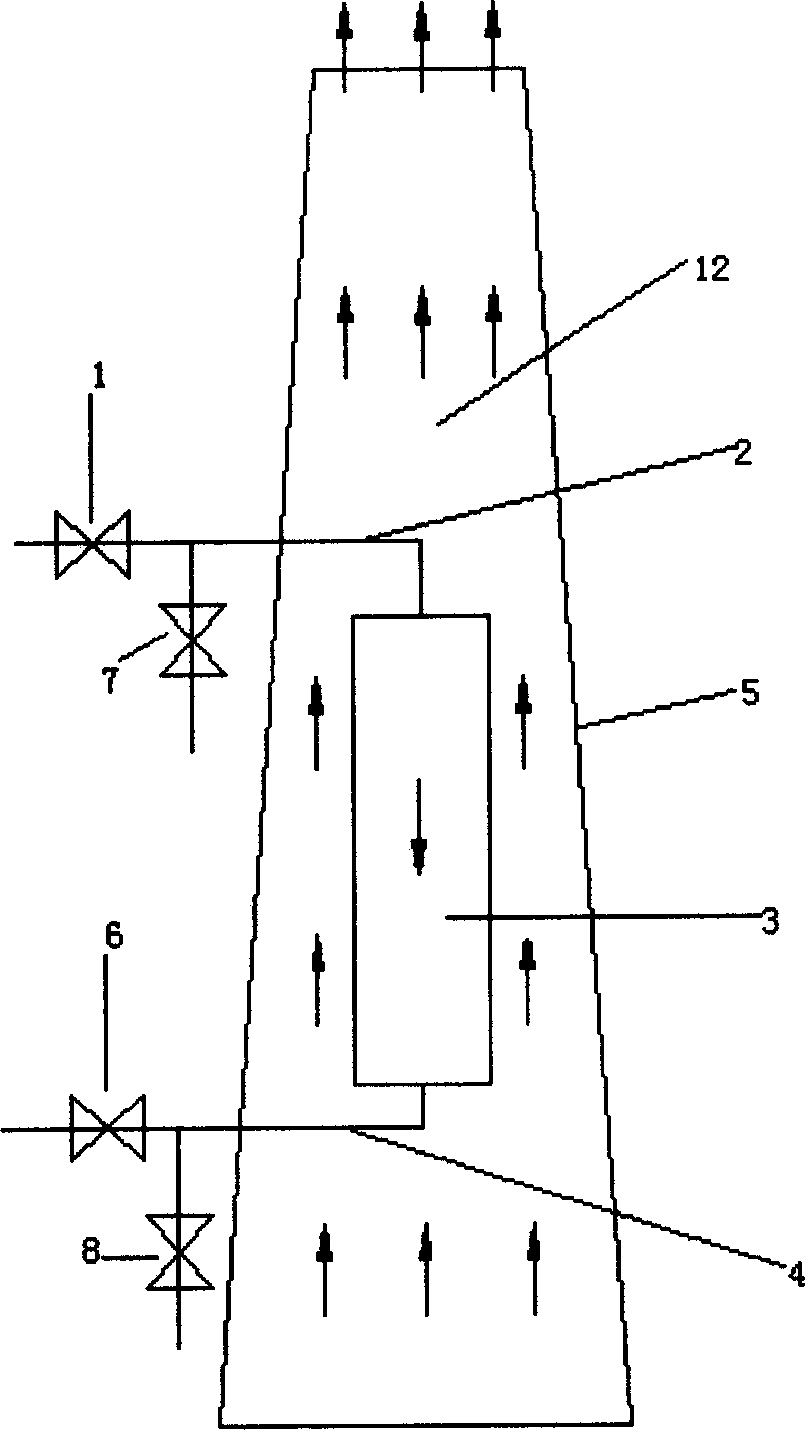

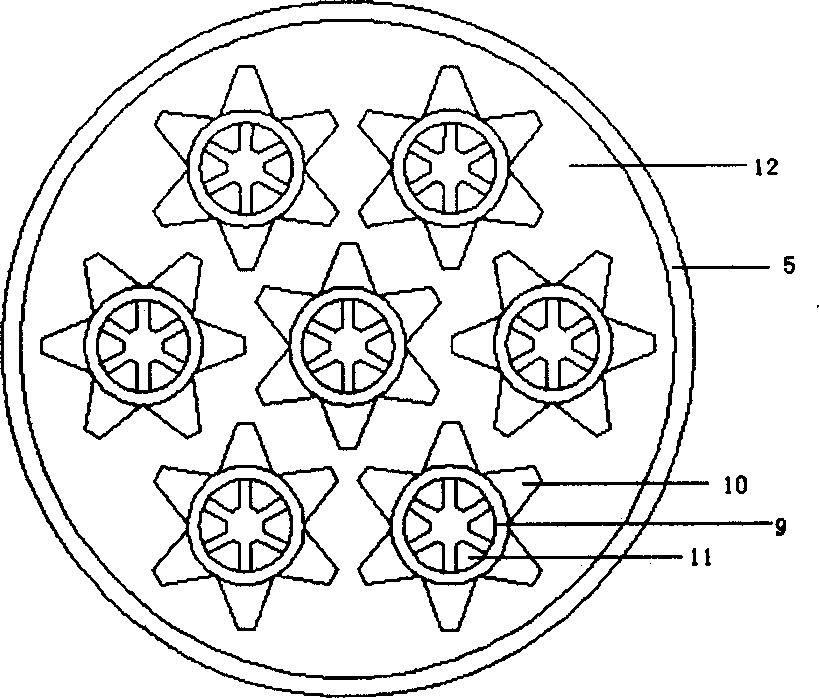

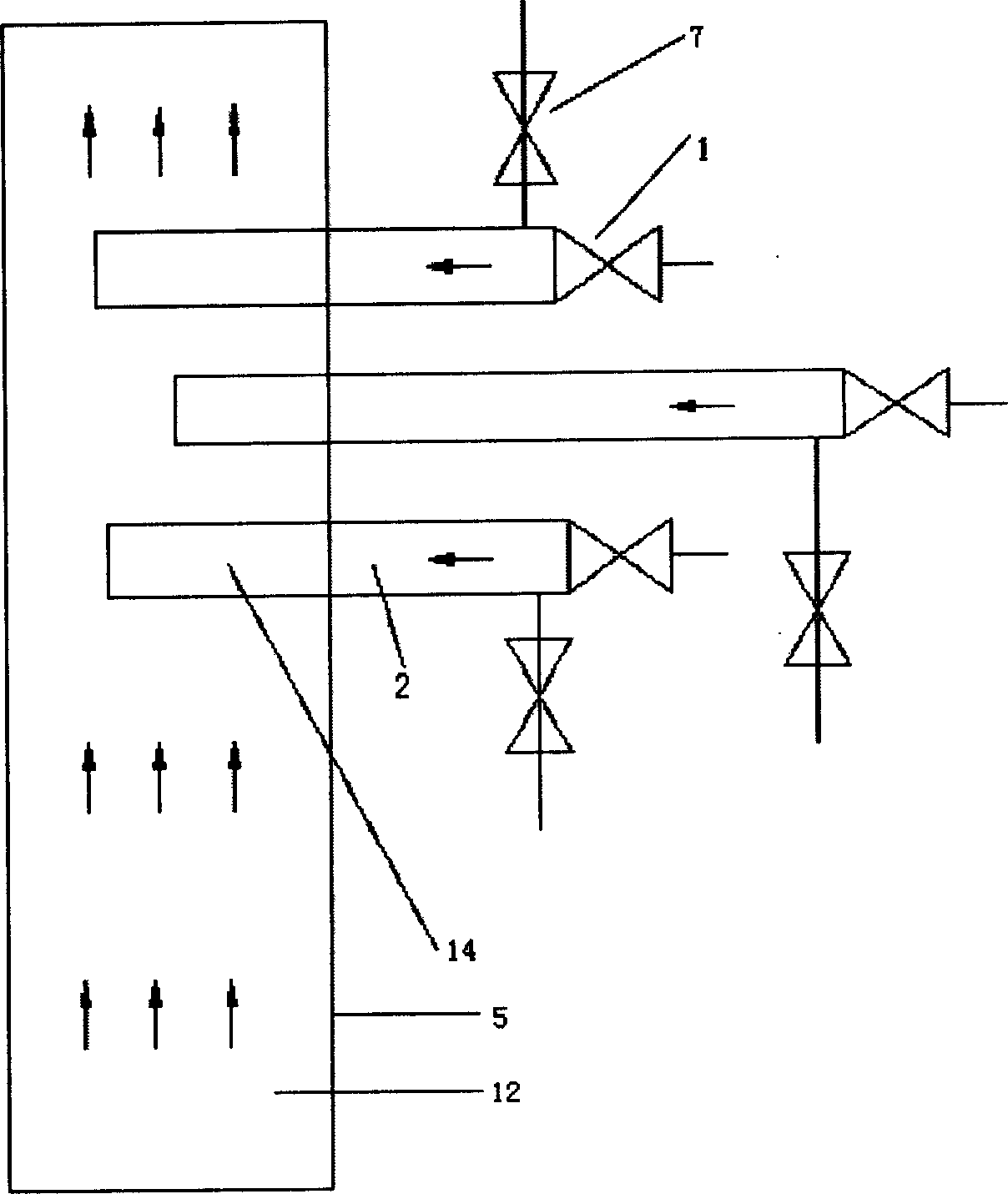

[0019] figure 1 and figure 2It is a structural schematic diagram of the first embodiment of the passive counter-flow finned tube thermophoresis dedusting tower provided by the present invention. The removal tower includes a tower body 5, a thermophoresis working tube bundle 3 fixed in the tower body, a dust-laden air inlet transition pipe section 2, a purified air outlet transition pipe section 4, a dust-laden air inlet valve 1 and a purified air outlet valve 6, which are arranged on The upper and lower inlet and outlet dampers on the tower body and the dust cleaning bypass system composed of air compressors, bypass valves 7, 8 and corresponding pipelines; The thermophoresis working pipe section 9 with fins has a length of 0.1-3m and an inner diameter of 1-10cm; the preferred length is 0.5-1.5m,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com