Combined electrostatic dust separator

A technology of electrostatic precipitator and electric field, which is applied in the field of composite electrostatic precipitator to achieve the effects of saving energy consumption, improving removal efficiency, and improving dust removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

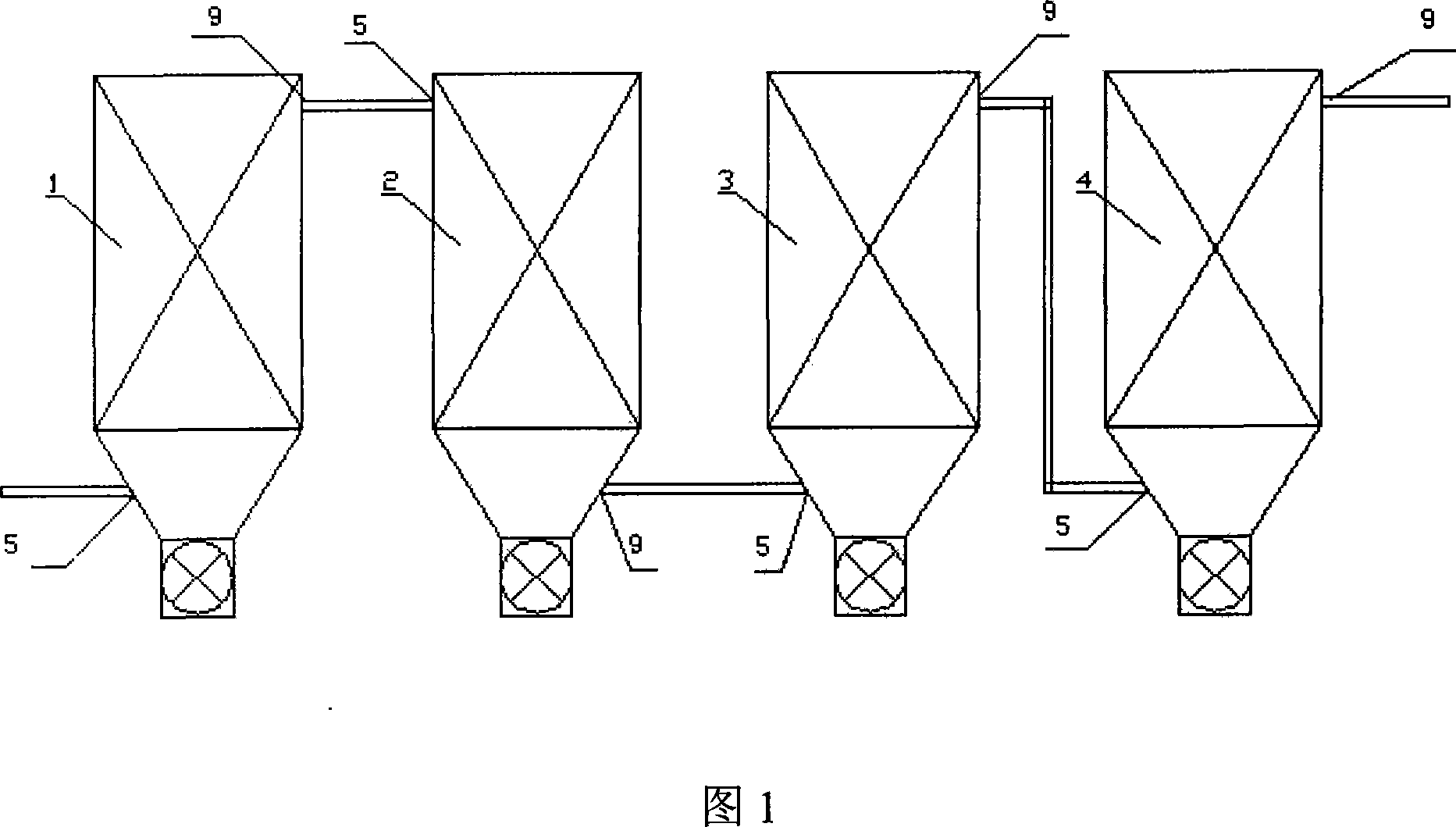

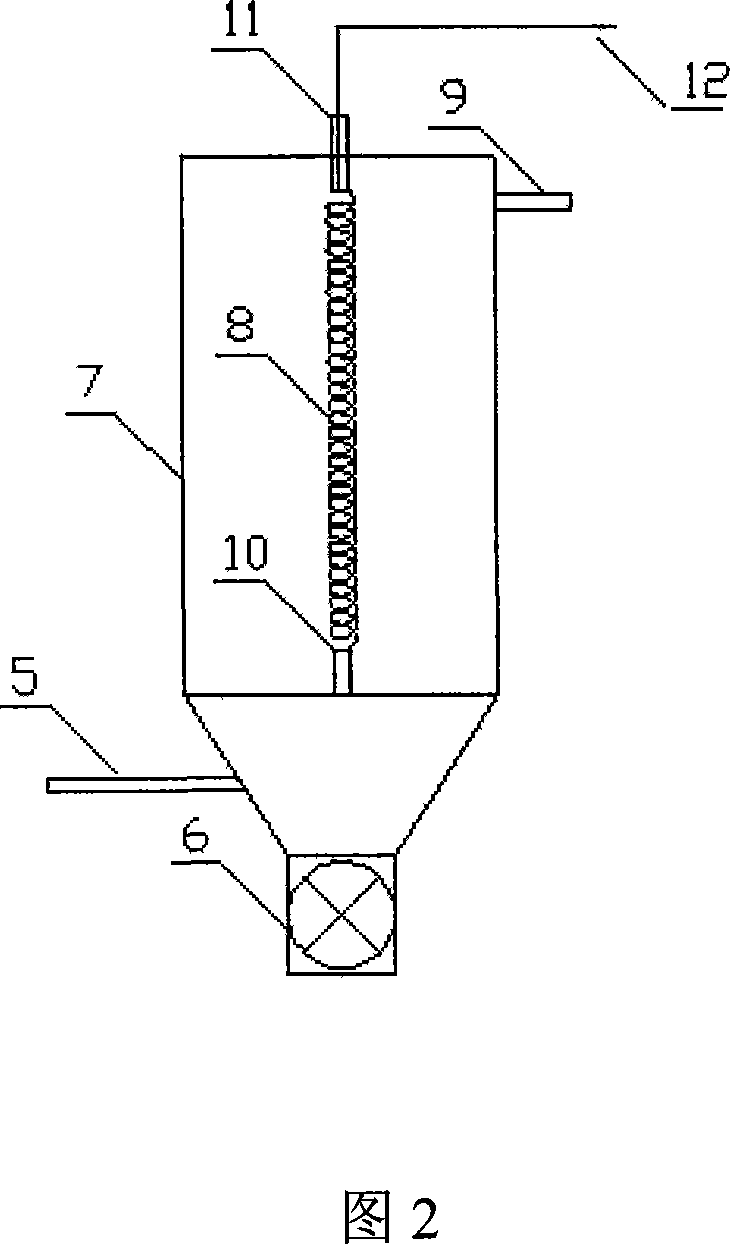

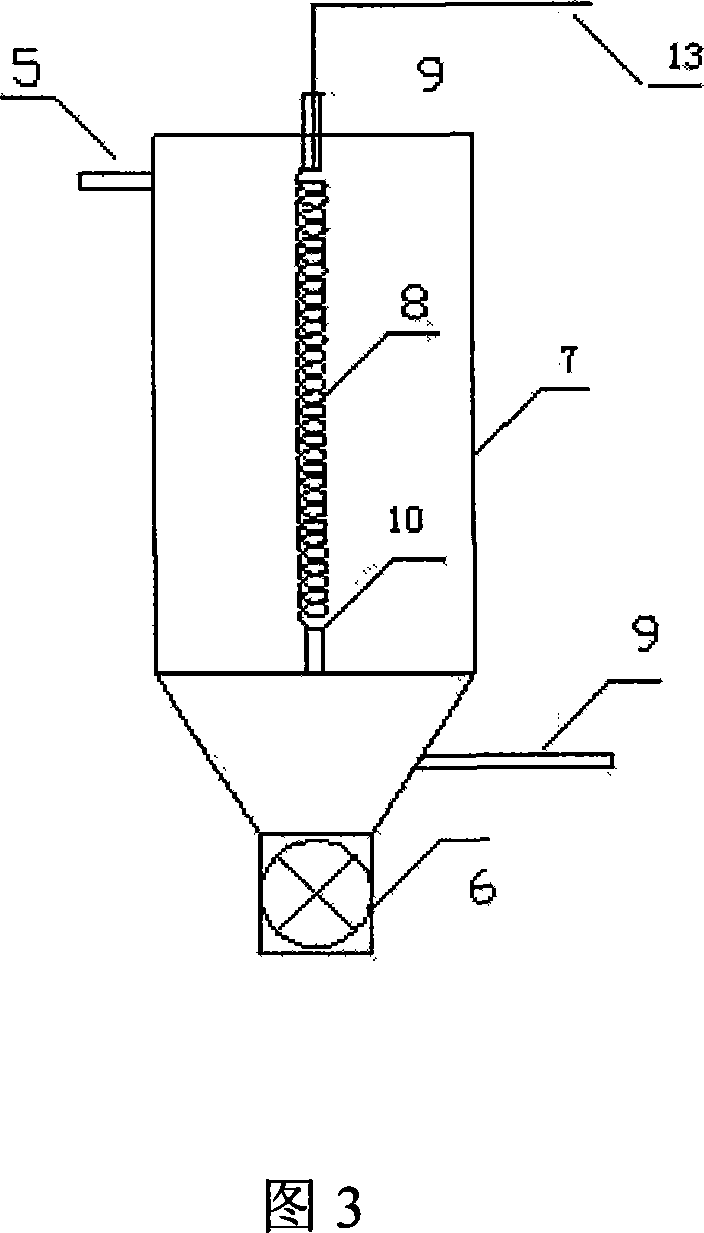

[0018] As shown in Figure 1, the composite electrostatic precipitator is characterized in that it has a first-stage DC discharge electric field 1, a second-stage pulse discharge electric field 2, a third-stage DC discharge electric field 3, and a fourth-stage DC discharge electric field 4. The electric field and the pulse discharge electric field have a dust collection area in the discharge area, the first-level DC discharge electric field 1, the third-level DC discharge electric field 3, and the fourth-level DC discharge electric field 4. The dust collection area is equipped with a flue gas inlet 5, and the first-level DC discharge Electric field 1, the third-level DC discharge electric field 3, the fourth-level DC discharge electric field 4, the upper end of the discharge area is provided with a flue gas outlet 9, the upper end of the second-level pulse discharge electric field 2 is provided with a flue gas inlet 5, and the second-level pulse discharge The dust collection are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com