Apparatus for automatically arranging casings and loading casings into hanger

A technology of automatic arrangement and shell parts, applied in the direction of spraying device, device for coating liquid on the surface, coating, etc., can solve the problems of poor effect and inconvenient design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

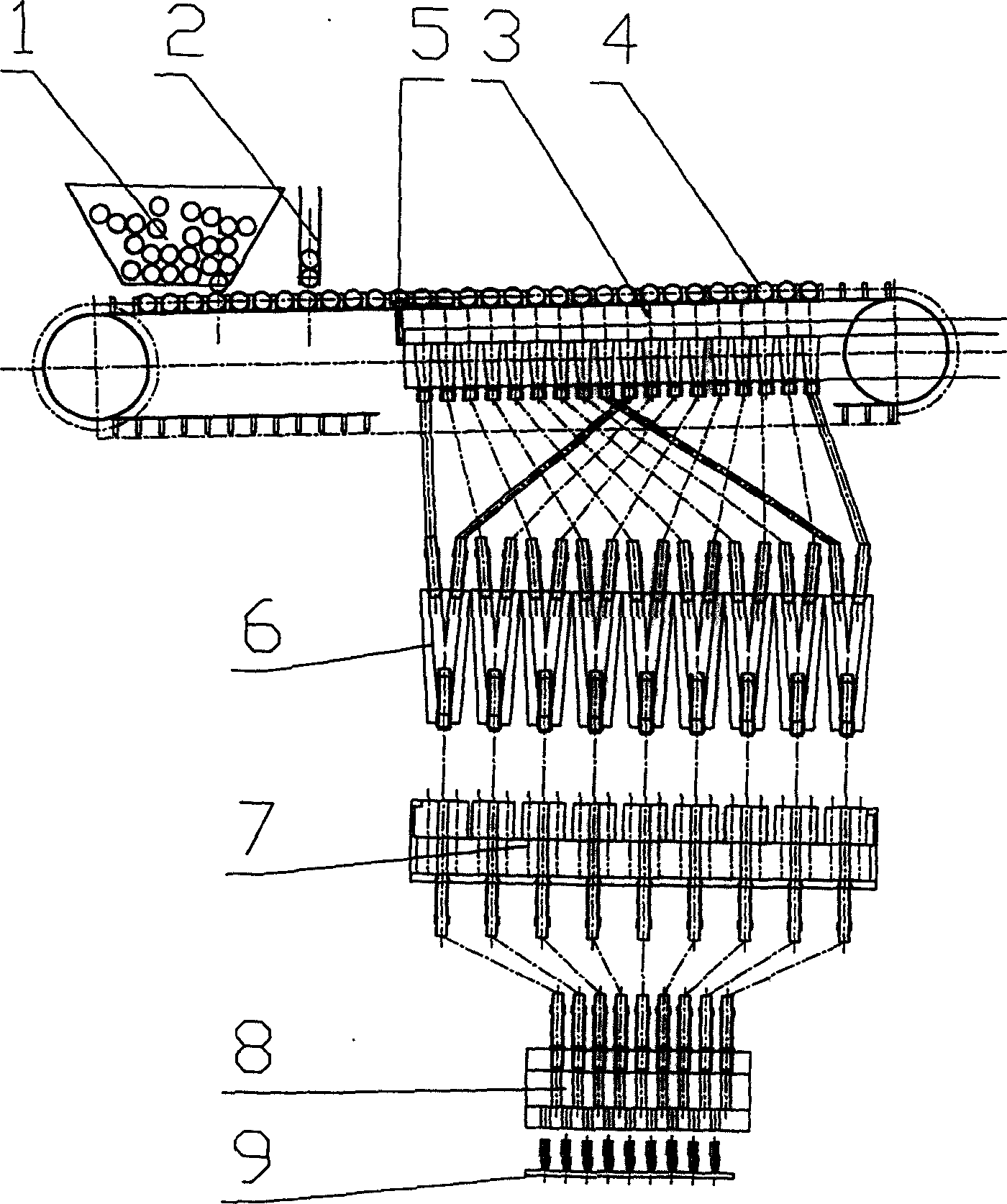

[0006] Control attached picture , its structure is that the upper part device 1 and the supplementary part device 2 are above the beginning end of the conveying line 3, the shell parts 4 are evenly arranged on the front end of the conveying line 3, and the ejection mechanism 5 is on the tail end of the conveying line 3, two in one The device 6 communicates with the corresponding holes in the ejection mechanism 5 through pipelines under the ejection mechanism 5. The dispersion device 7 is located below the two-in-one device 6, and the hole at the bottom of the two-in-one device 6 is connected to the upper part of the dispersion device 7 through the pipeline. Corresponding holes are communicated, and hanger 9 is positioned at the below that arranges and drops device 8.

[0007] work process:

[0008] The shell parts 4 are evenly distributed on the conveying line 3 through the loading device 1 and the replenishing device 2 . The head and tail of the shell 4 may be in two direct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com