Method and device for testing deep of film

A technique for measuring devices and measuring methods, which is applied in the direction of measuring devices, optical devices, chemical instruments and methods, etc., can solve the problems of narrowness, low reflectivity, and decreased reliability of film thickness measurement, and achieve the elimination of deviation and film thickness measurement. Effect of Accuracy Improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

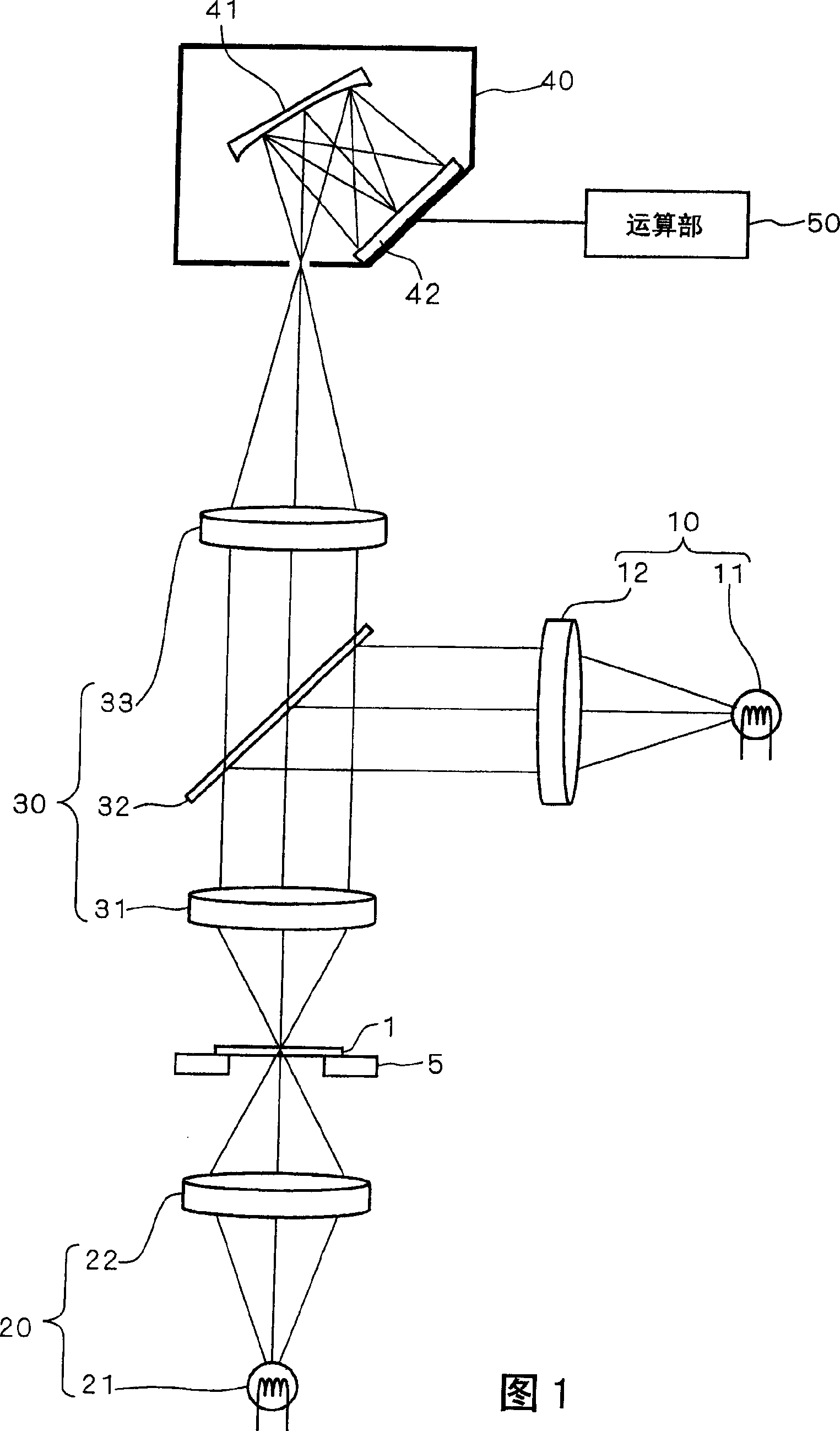

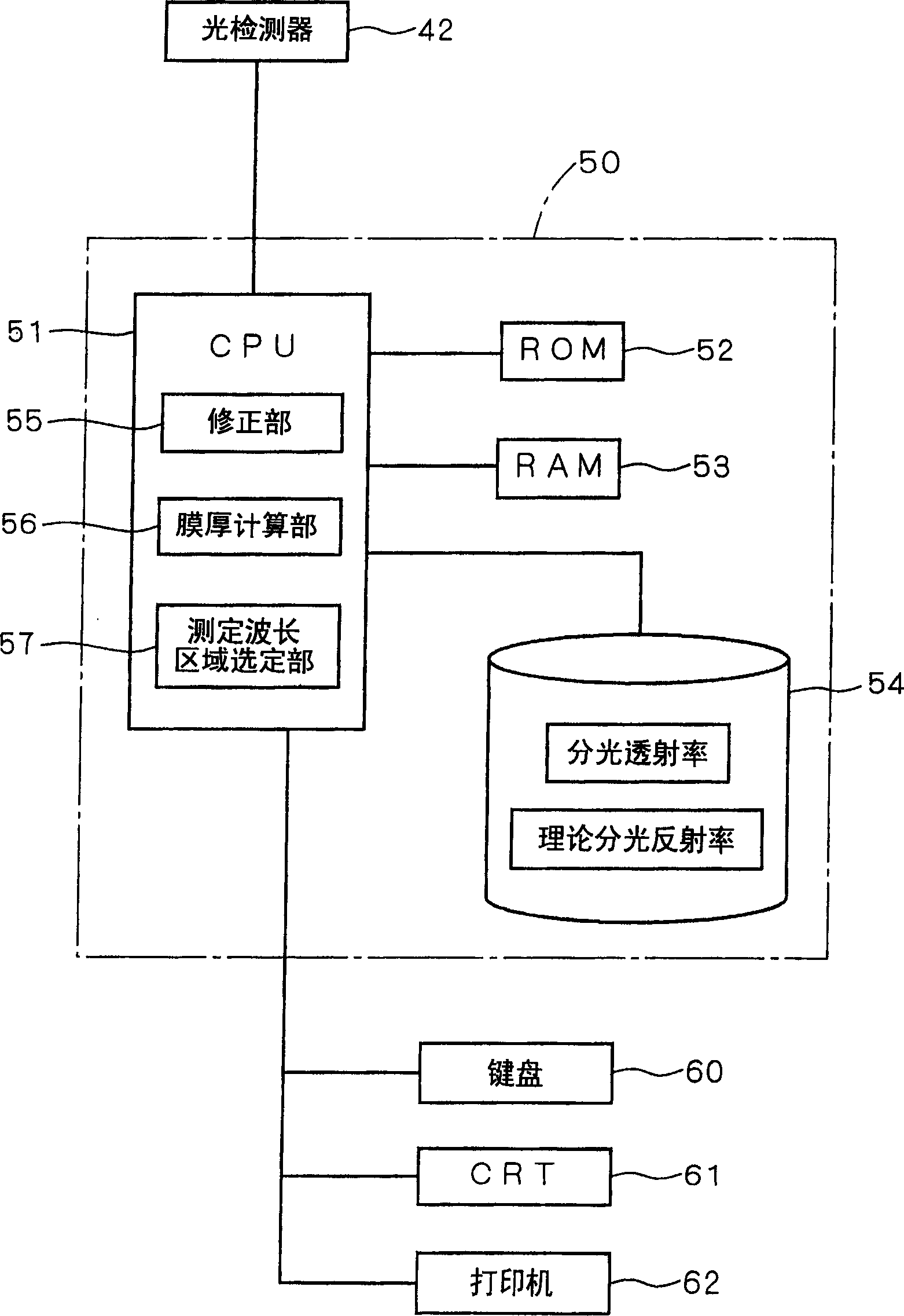

[0042] FIG. 1 is a view showing the structure of a film thickness measuring device of the present invention. The film thickness measurement device includes: a first illumination optical system 10 , a second illumination optical system 20 , and an imaging optical system 30 . The first illumination optical system 10 includes a halogen lamp 11 that emits white light and an illumination lens 12 . The illumination lens 12 is constituted by, for example, a combination of condensing lenses, and a field stop (not shown) and the like are attached to the condensing lenses. Light emitted from the halogen lamp 11 enters the imaging optical system 30 through the illumination lens 12 .

[0043] The imaging optical system 30 is composed of an objective lens 31 , a half mirror 32 and an imaging lens 33 . The illumination light from the first illumination optical system 10 is reflected by the half mirror 32 and irradiates the upper surface of the sample 1 placed on the sample stage 5 through...

no. 2 approach

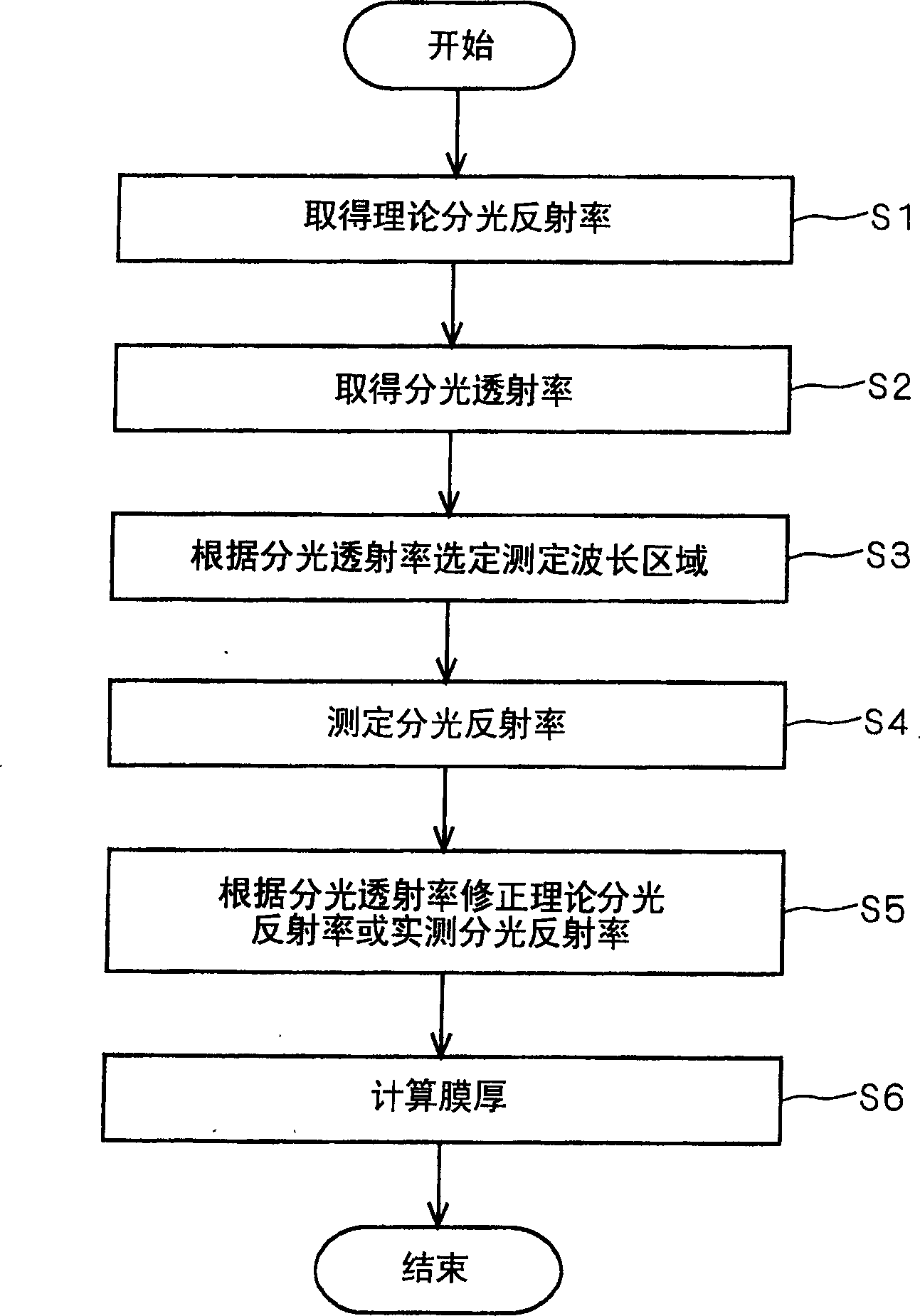

[0077] Next, a second embodiment of the present invention will be described. The device structure of the film thickness measuring device of the second embodiment is the same as that of Fig. 1, figure 2 As in the first embodiment shown, the processing procedure of the film thickness measuring method is also substantially the same as in the first embodiment. The difference between the second embodiment and the first embodiment is that when calculating the film thickness of the color filter, the difference between the theoretical spectral reflectance and the measured spectral reflectance is weighted corresponding to the spectral transmittance.

[0078] In the second embodiment, when measuring the film thickness of the color filter, the above-mentioned image 3 Steps S1 to S5 are exactly the same processing. Then proceed to step S6, and the film thickness calculation unit 56 calculates the film thickness of the color filter to be measured by comparing the corrected theoretical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com