Three-dimensional conveyer

A conveyor, three-dimensional technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of conveyor chain bending, large area of conveyor chain, unsuitable sprockets, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

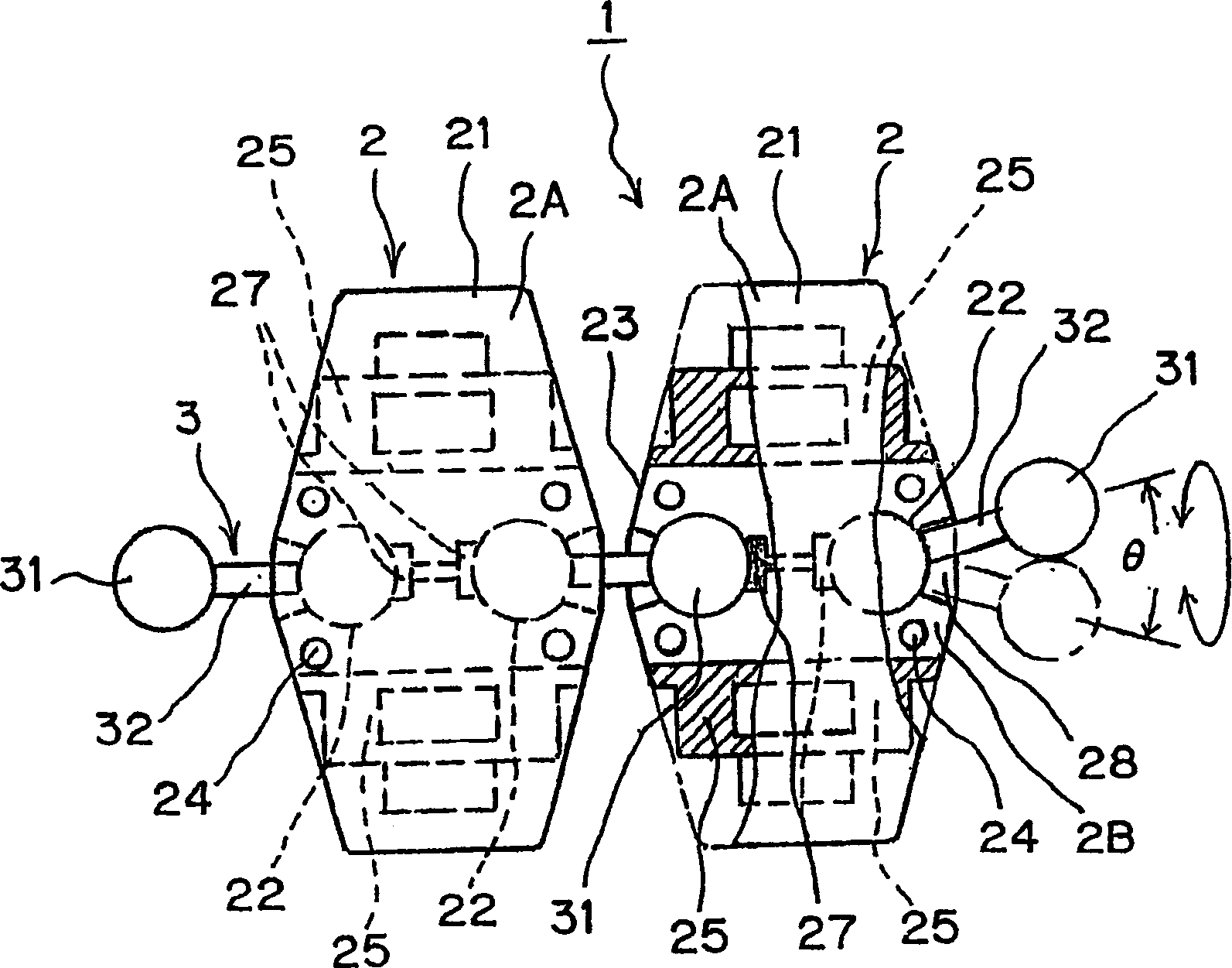

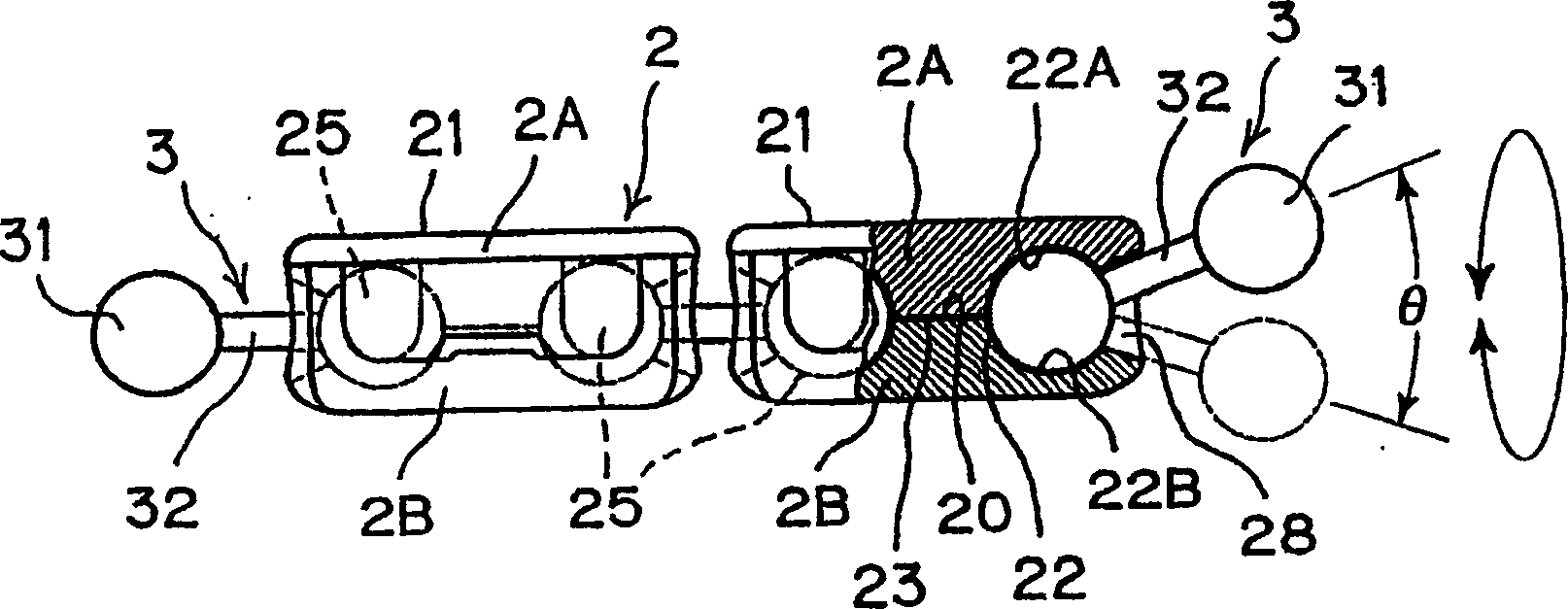

[0058] The following by reference Figure 1-14 The present invention is explained in detail.

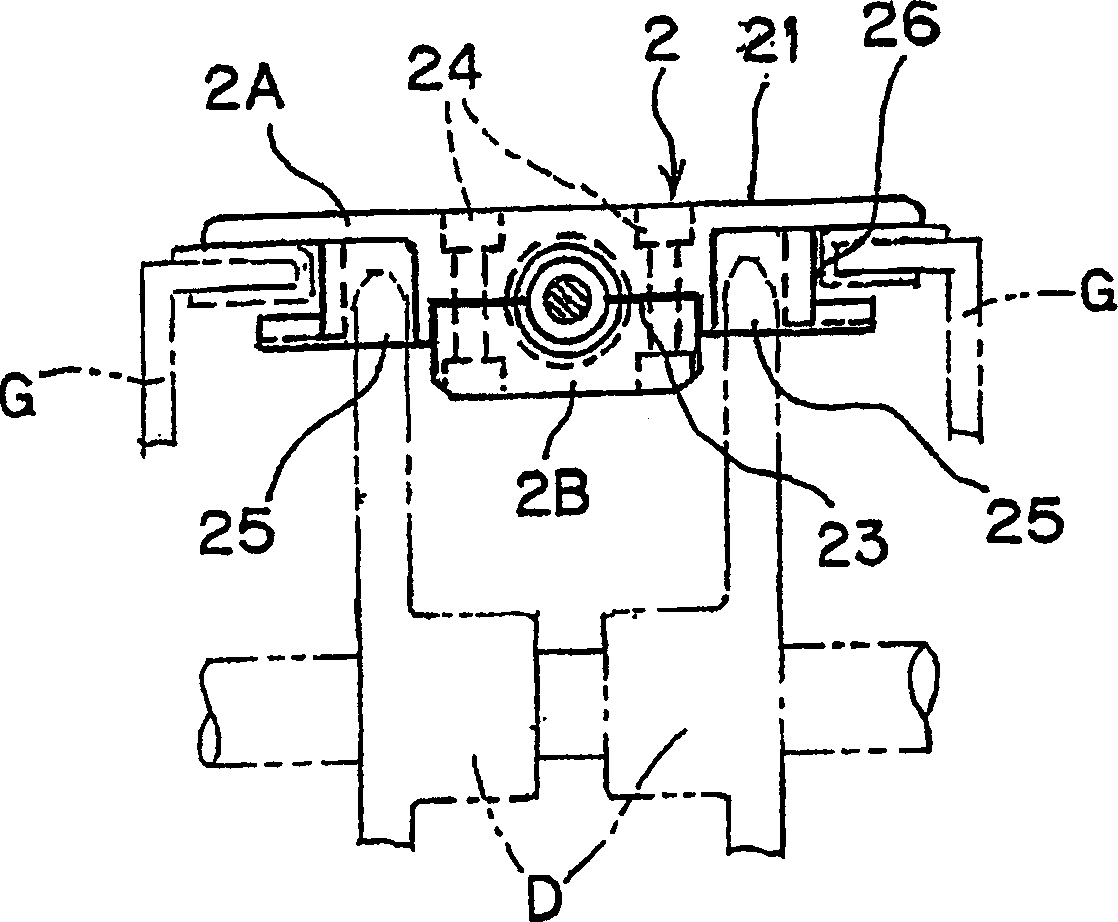

[0059] The number 1 indicates the teleporter. The conveyor 1 is composed of several top trays 2 and connectors 3 for sequentially connecting adjacent top tray units. Each top tray unit 2 is made up of a top tray 2A having a top tray surface 21 for retaining items to be conveyed thereon and a tray bottom surface 23, and a buckle tray 2B having a tray bottom surface fitted to the top tray 2A The upper buckle surface 20.

[0060] On the top plate unit 2, two ball-holding cavities 22 are respectively formed in a nearly hemispherical shape, parallel to the traveling direction of the top plate unit.

[0061] By combining the nearly hemispherical concave surface 22A formed on the bottom surface 23 of the top plate 2A with the nearly hemispherical concave surface 22B formed on the buckle surface 20 of the buckle plate 2B, the ball-holding cavity 22 is formed in a nearly spherical shape. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com