Self-supporting timber box for the support and thermal insulation of an impermeable tank membrane

A self-supporting, thin-film technology, applied in the direction of bulk cargo, fixed-capacity gas storage tanks, applications, etc., can solve the problems of membrane rupture, working costs, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

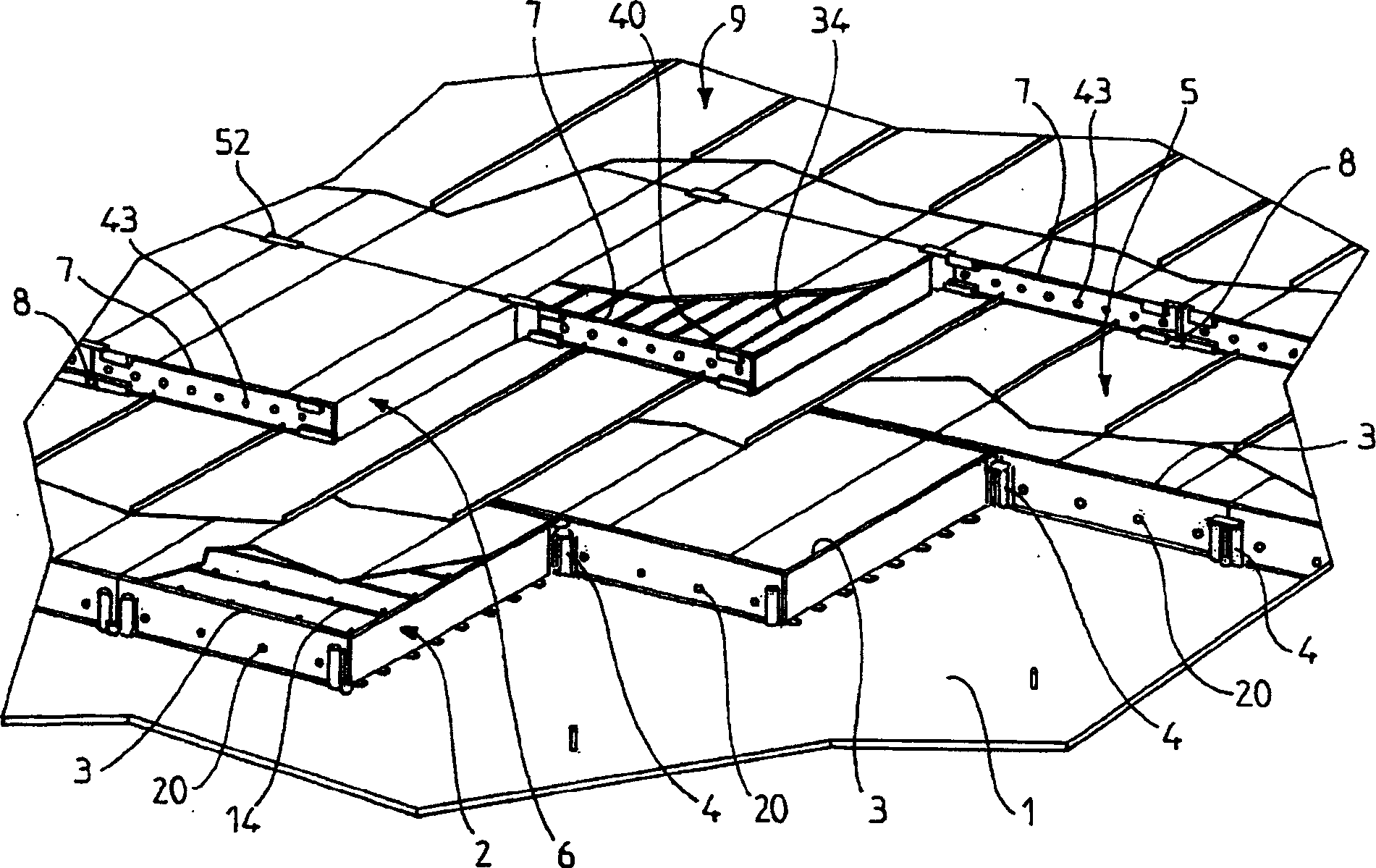

[0031] The general structure of a sealed and insulated storage tank contained and fixed in the double hull of a methane tanker type vessel is known and is polyhedral in shape. Therefore, this specification will be limited to areas of the tank wall such as figure 1 As shown in , it should be understood that all tank walls have similar constructions.

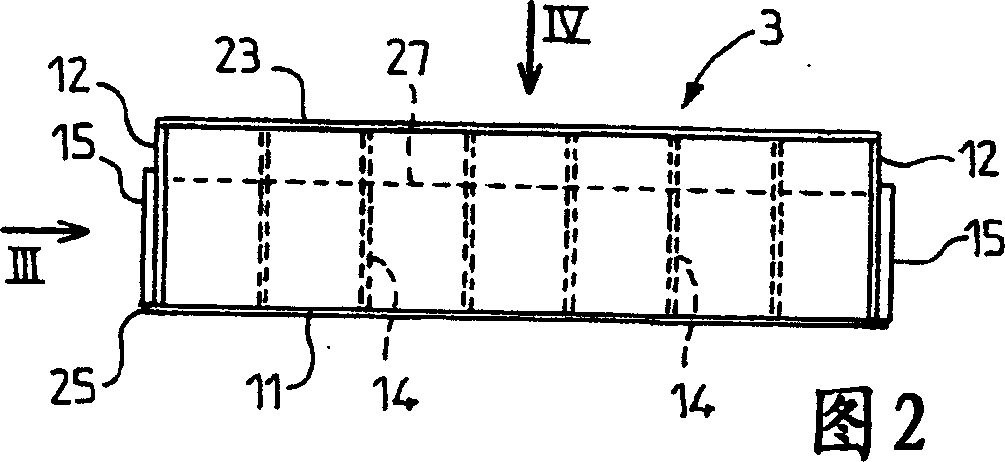

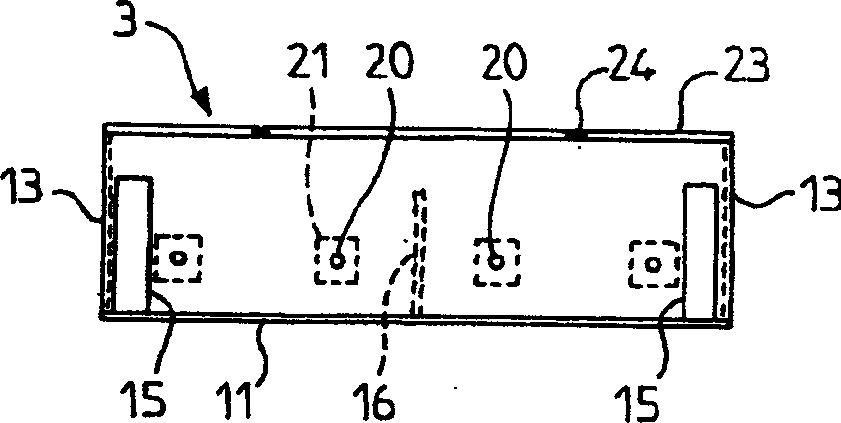

[0032] figure 1The double hull area of the ship, indicated by reference numeral 1, is shown. The tank wall comprises the following parts arranged in sequence along its thickness: a second layer of insulation 2 formed by a box 3 juxtaposed on the double hull 1 and passed through a second holding part 4 and supported on the double hull; second impermeable membrane 5, the second impermeable membrane 5 is supported by the box 3; A holding member 8 is juxtaposed and supported on the second impermeable membrane 5, the first holding member 8 itself is fixed on the second holding member 4; and a first impermeable membrane 9, which is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com