Construction for attaching net member to chair seat or backrest frame

A frame and component technology, which is applied in the structural field of installing grid components on a frame for a seat or a backrest of a seat, can solve problems such as inability to provide elasticity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

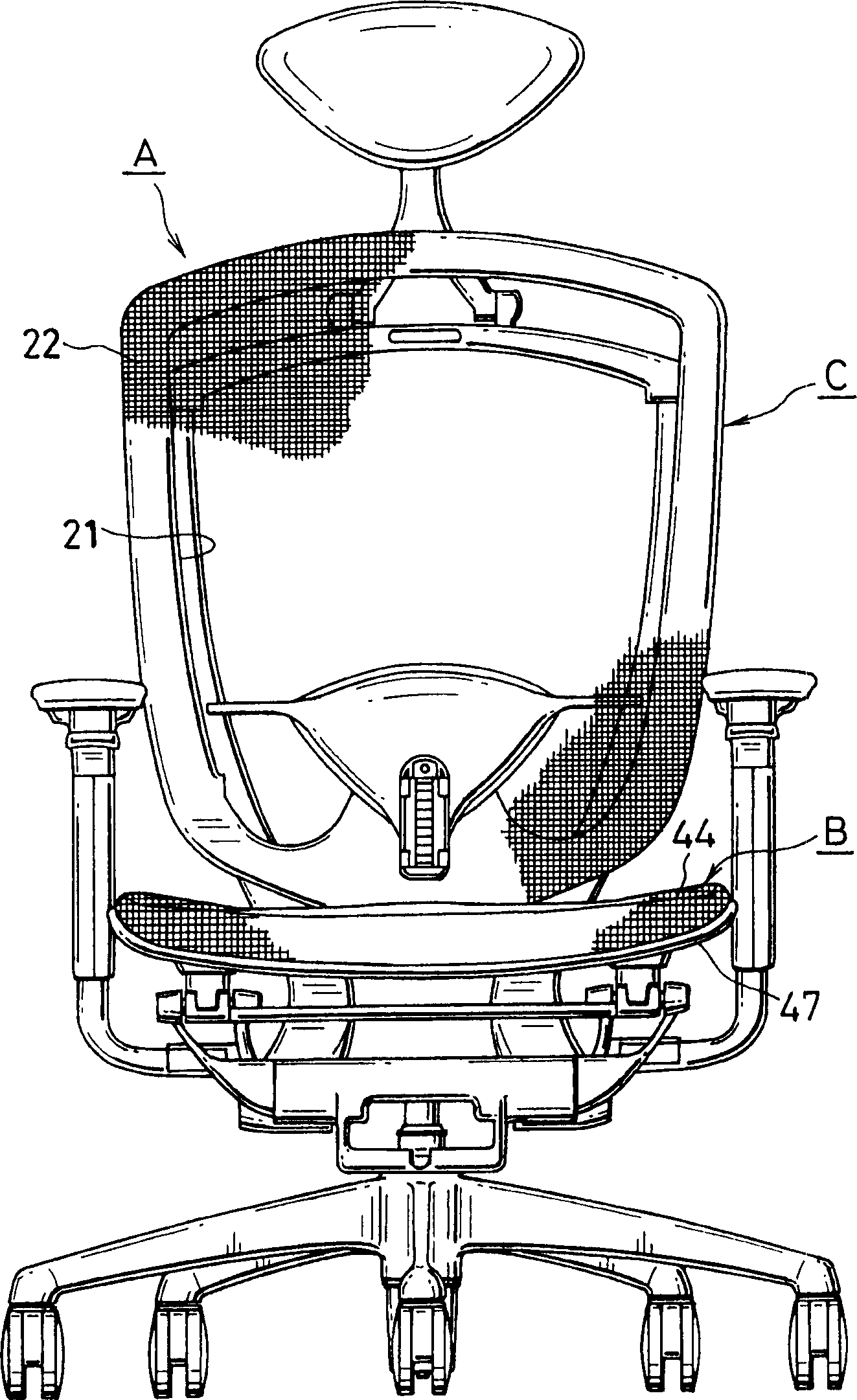

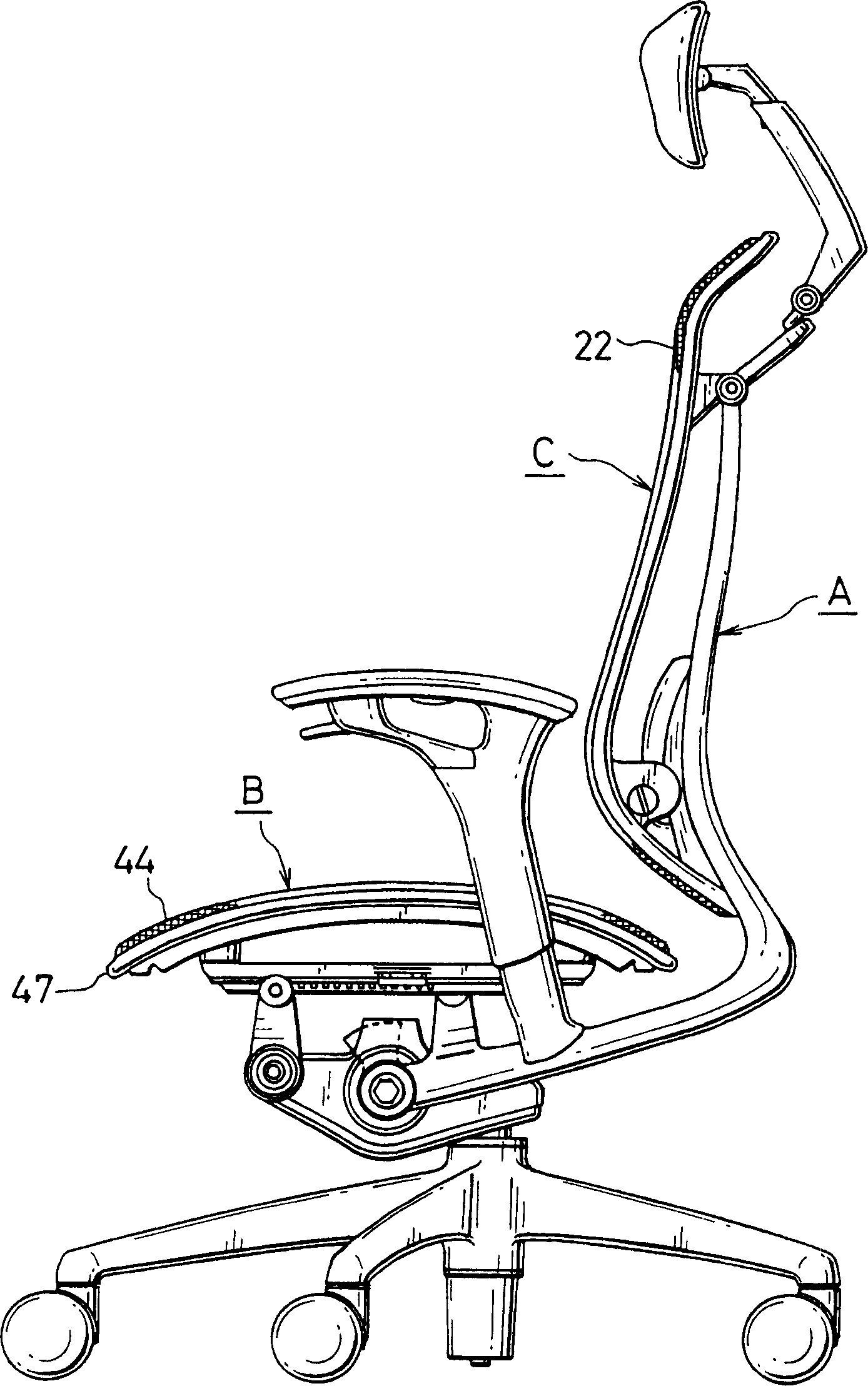

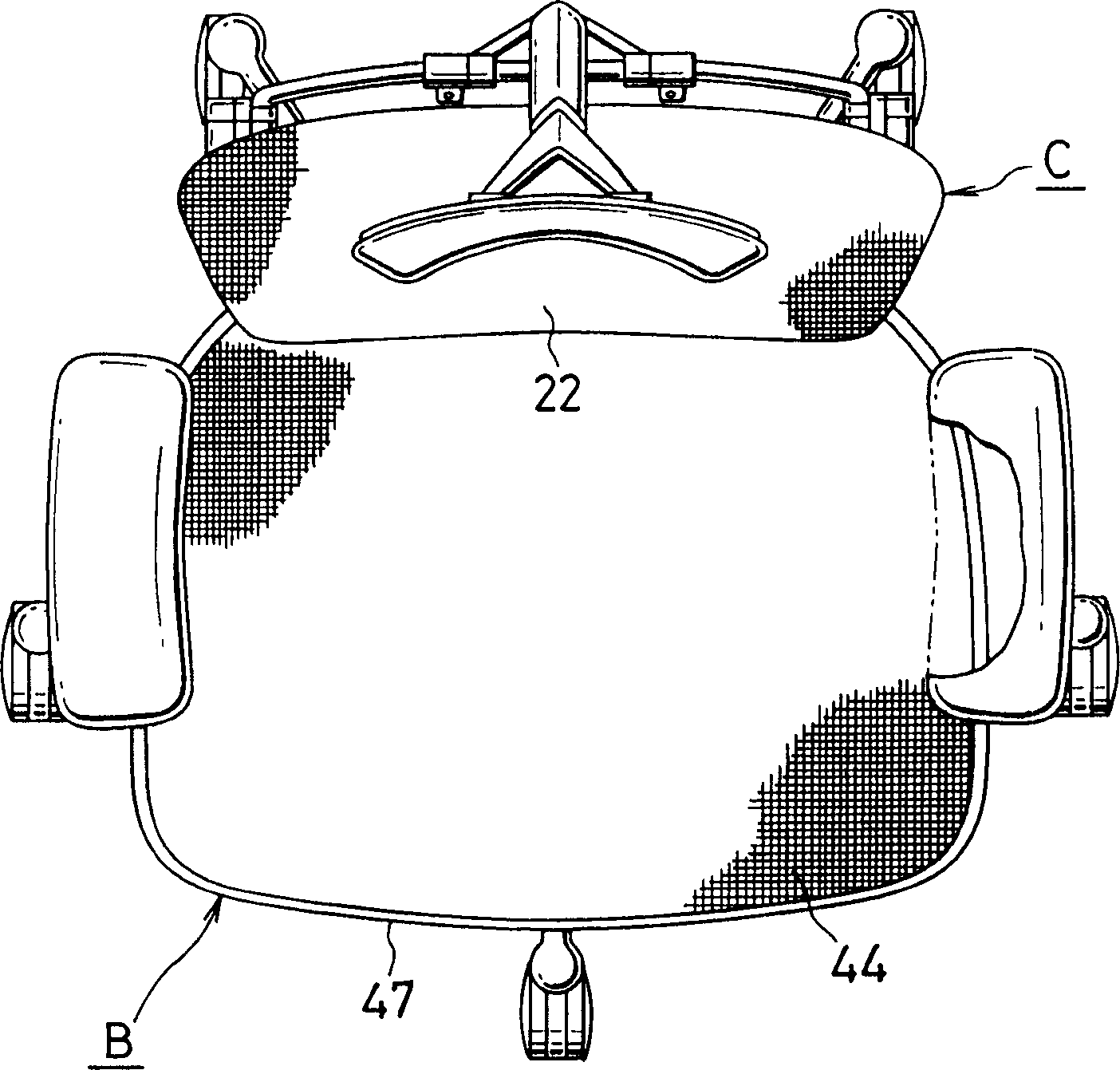

[0044] figure 1 is a front view of Seat "A" with a structure in which mesh parts are mounted to the seat or back frame, figure 2 is its right view, image 3 is its top view.

[0045] Next, a first embodiment of the present invention will be described. The present invention is not only applicable to figure 2 The seat portion "B" of the seat "A" can also be applied to the backrest "C" of the seat "A".

[0046] Such as Figure 4 with 5 As shown, in seat "B", the perimeter of a grid member 2, such as high tensile plastic, is placed over the perimeter of the closed loop seat frame 1 and folded over. A joint frame 3 similar in shape to the seat frame 1 is placed on the lower surface of the folded portion 2 a and connected by screws 4 .

[0047] A plurality of threaded holes 5 and through holes 6 are respectively formed on the coupling frame 3 on the lower surface of the seat frame 1, and the positions of the threaded holes and the through holes correspond to each other.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com