Symmetric beamline and methods for generating a mass-analyzed ribbon ion beam

A technology of mass analysis and mass analyzer, applied in the direction of ion beam tubes, discharge tubes, electrical components, etc., can solve the problems of beam expansion and difficulty in providing low-energy high-current beams, and achieve injection uniformity and transport loss Approximately homogeneous, prevents contamination and particles from reaching the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

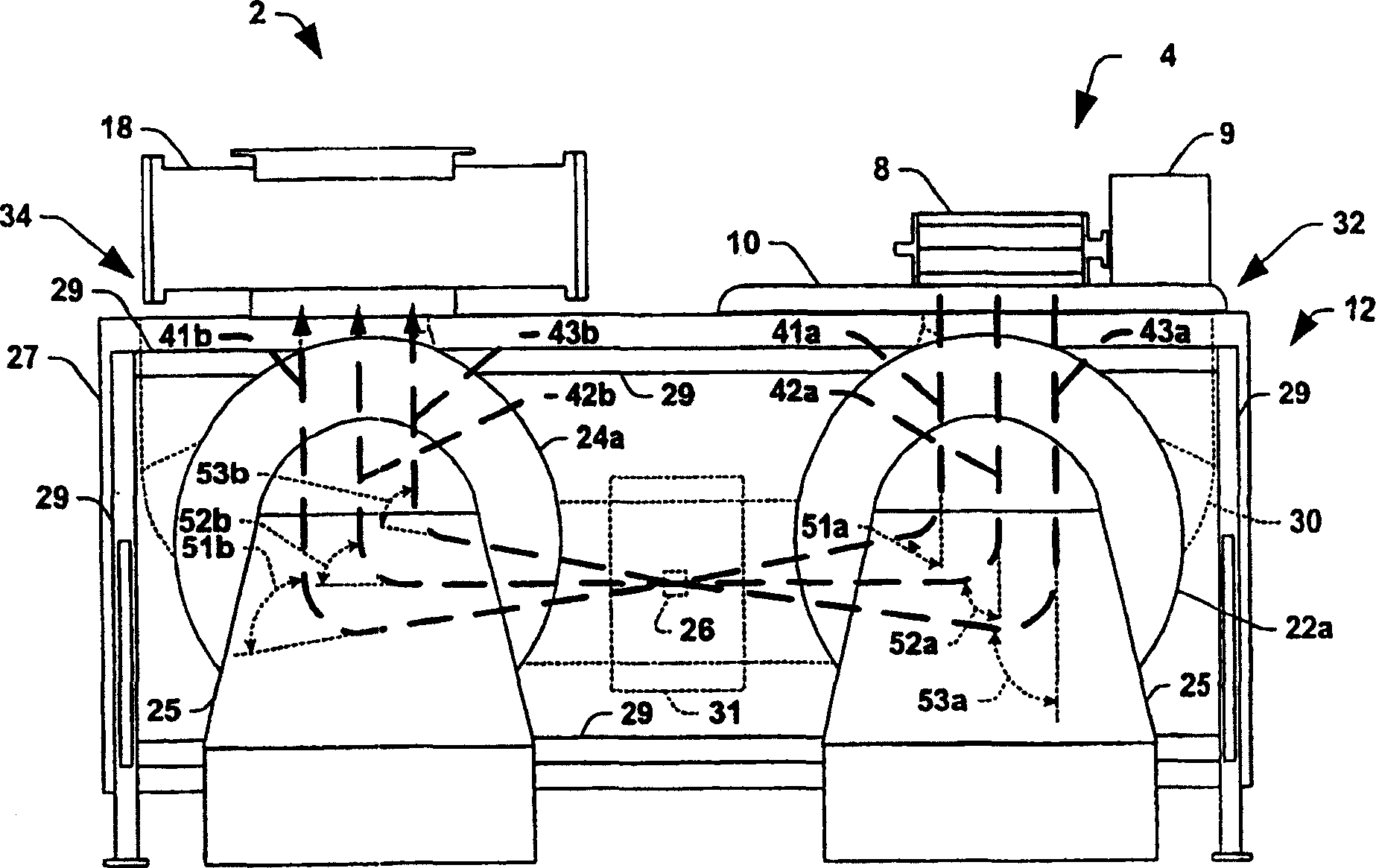

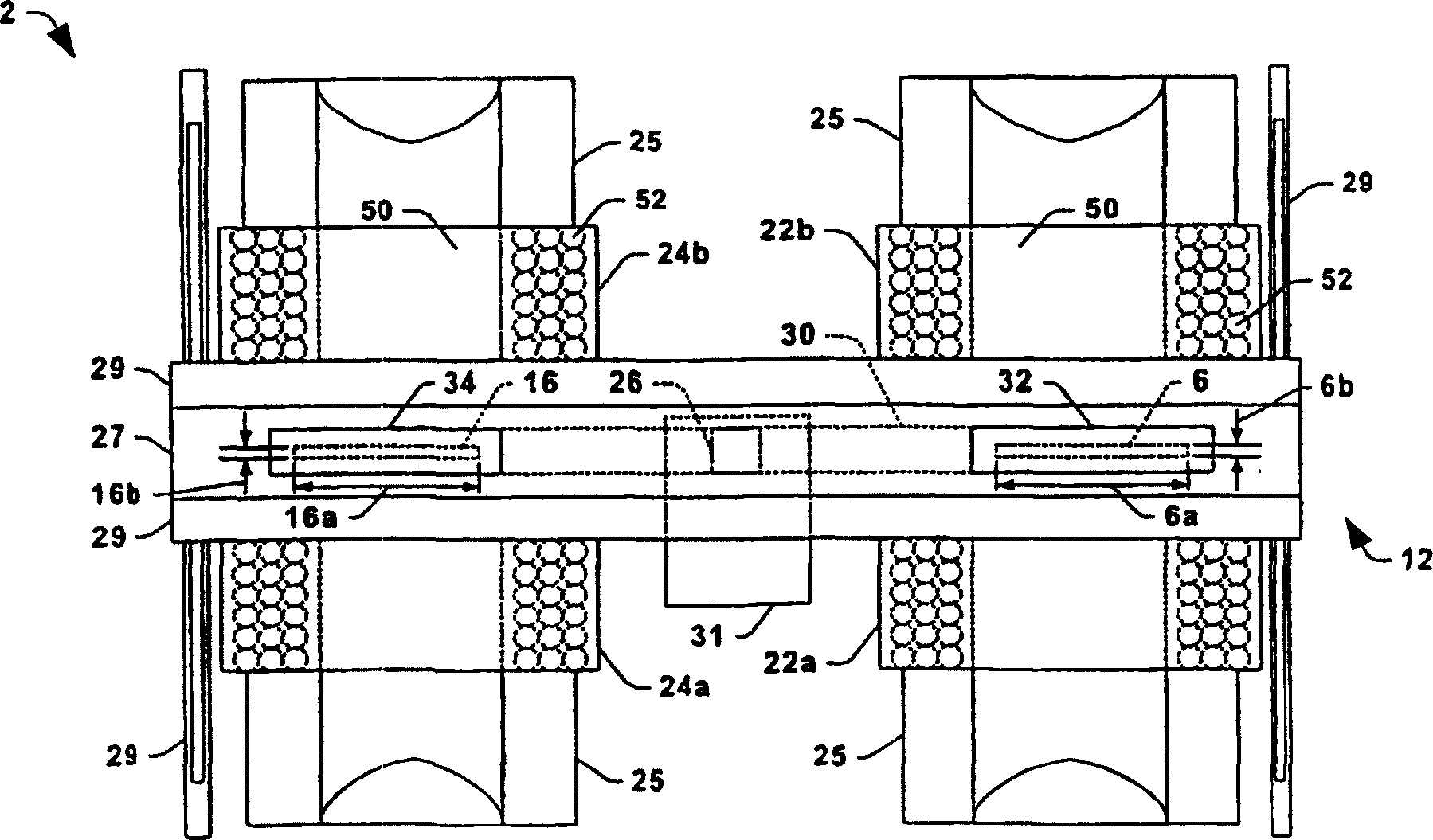

[0028] The present invention will now be described with reference to the drawings, and the same reference numerals are used to denote the same elements in all the drawings. The present invention provides a method and system for providing a mass-analyzed ribbon beam for ion implantation of workpieces, such as semiconductor wafers. Hereinafter, an embodiment of the present invention is illustrated and described with reference to the accompanying drawings. The illustration and the following description are exemplary in nature and not restrictive. Therefore, it is understood that variations of the system and method shown, as well as other embodiments than those shown here, are deemed to fall within the scope of the present invention and the scope of the appended claims.

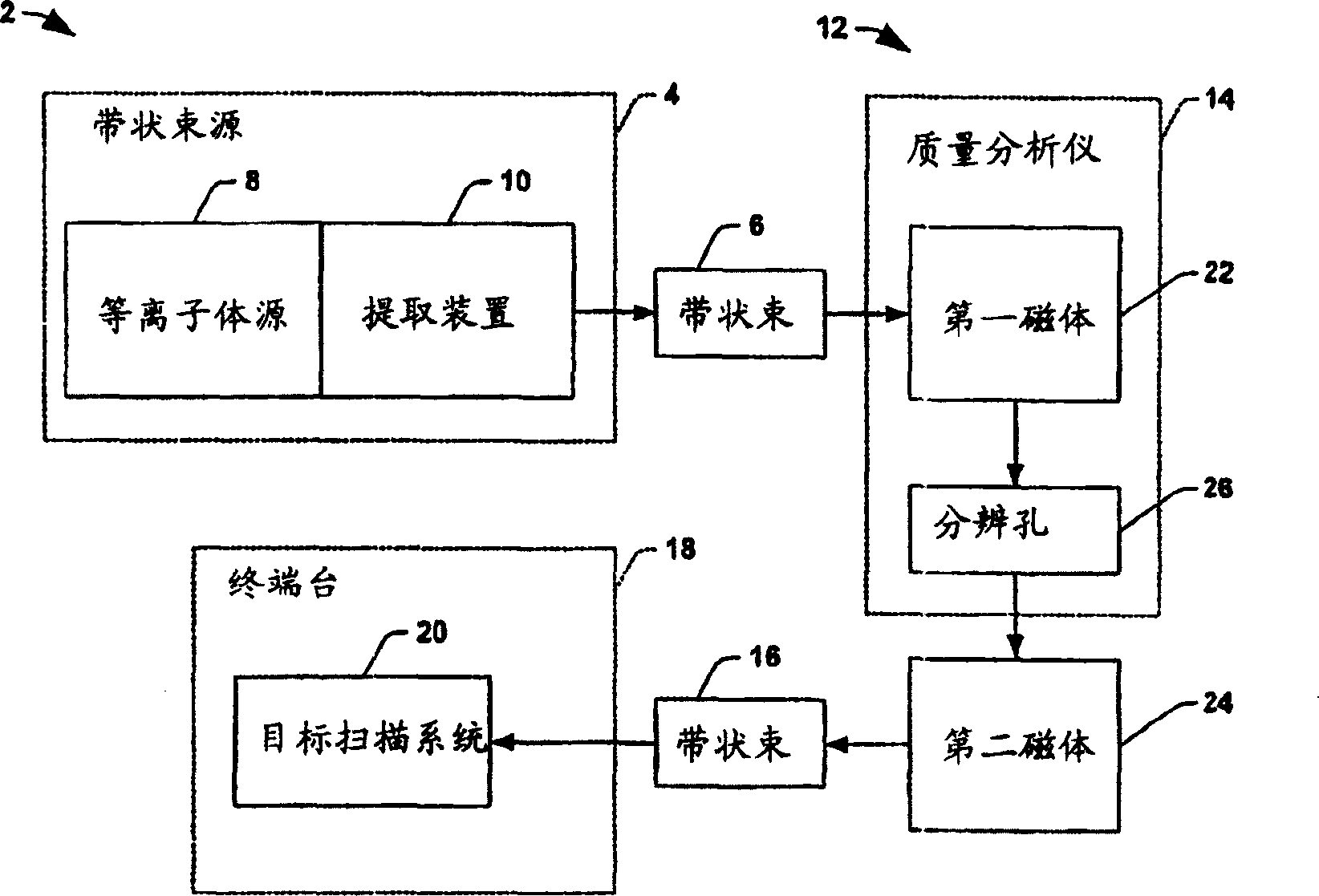

[0029] Start referencing figure 1 with 2a -2c, the present invention provides an ion implantation system 2 including an ion source 4 for generating an elongated (eg, ribbon) ion beam 6 along a longitudinal beam path...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com