Ink scraper

A squeegee and ink technology, used in rotary printing presses, printing, printing presses, etc., can solve the problem of difficult to control printing force, achieve the effect of uniform ink thickness and improve printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

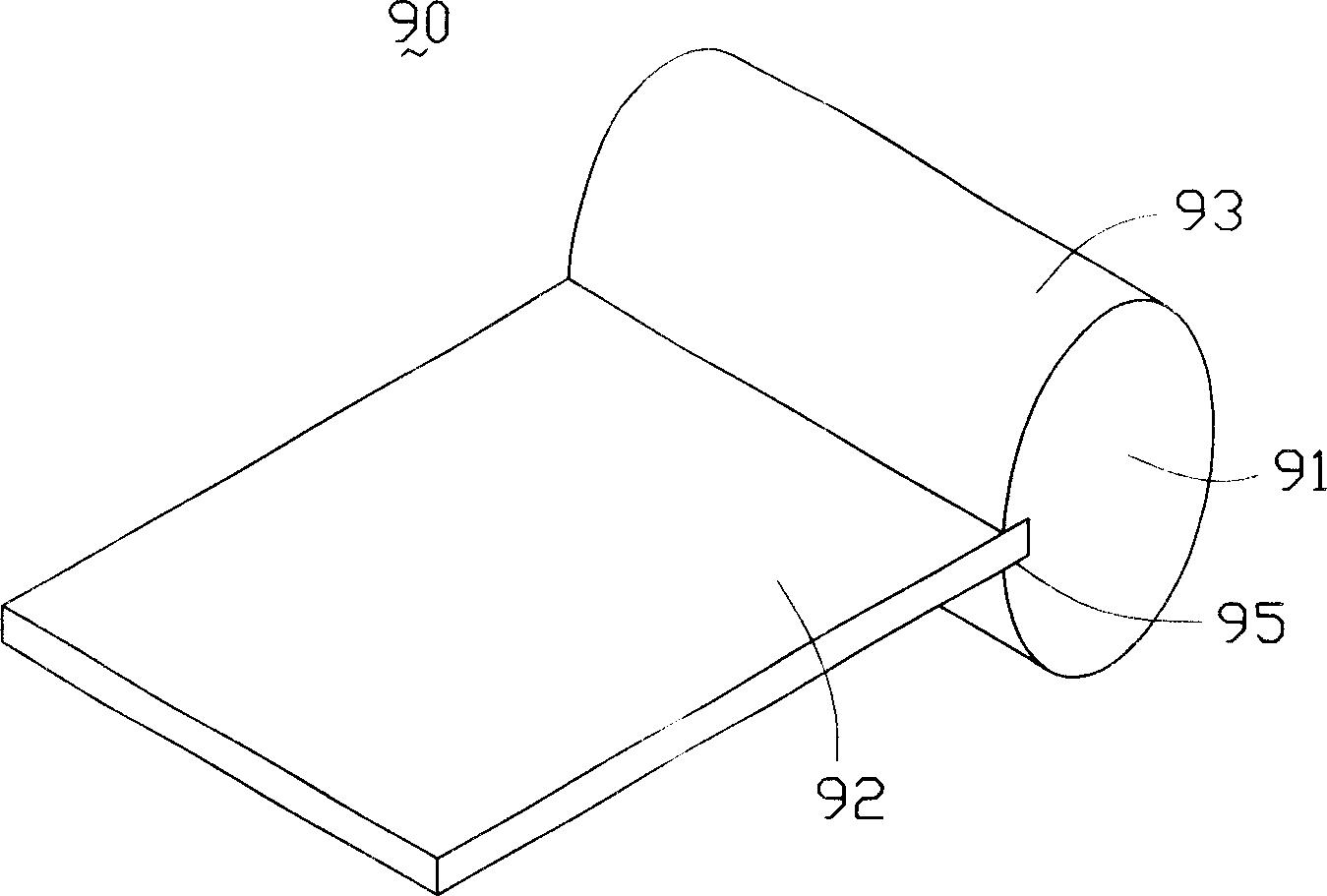

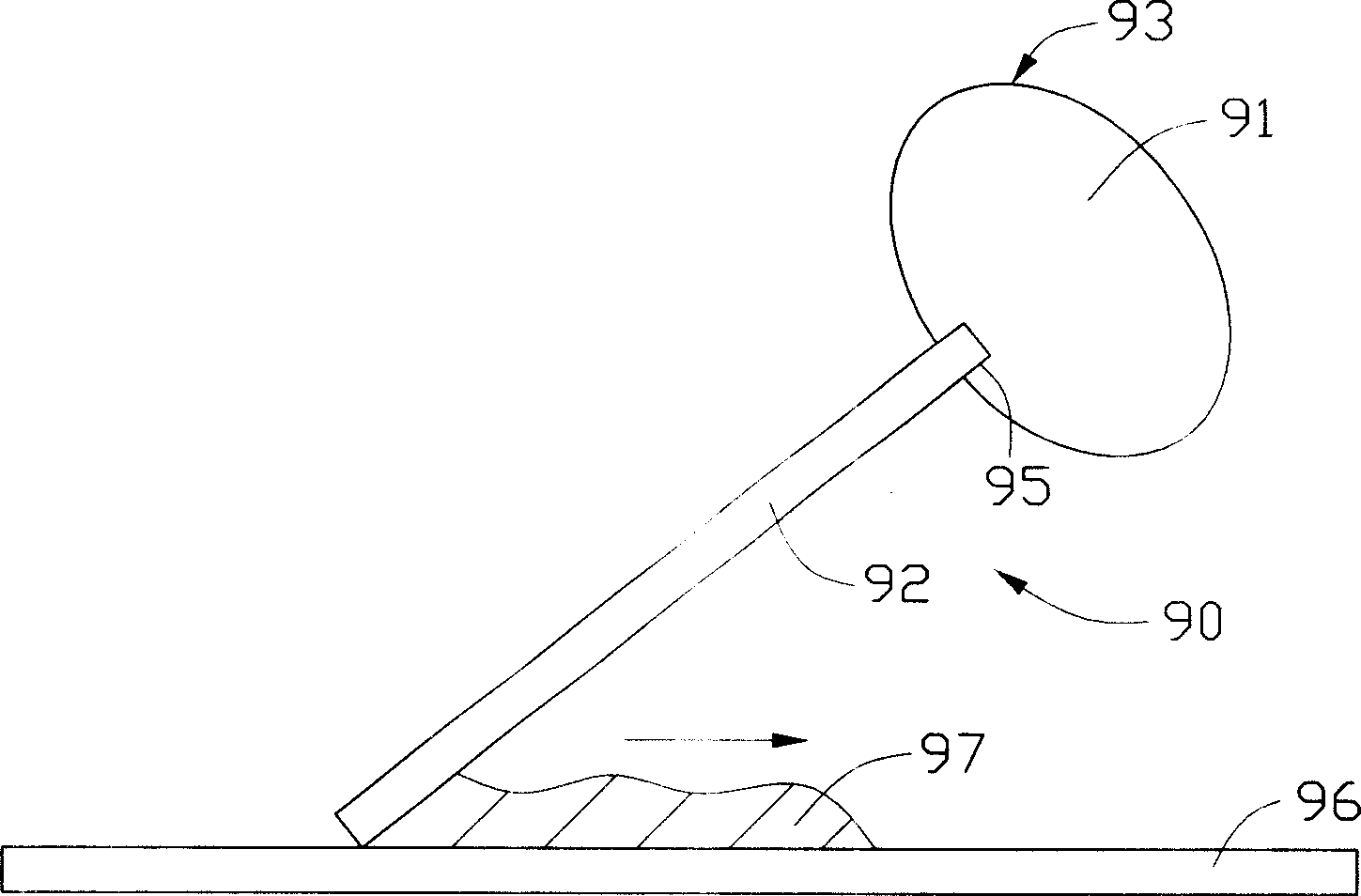

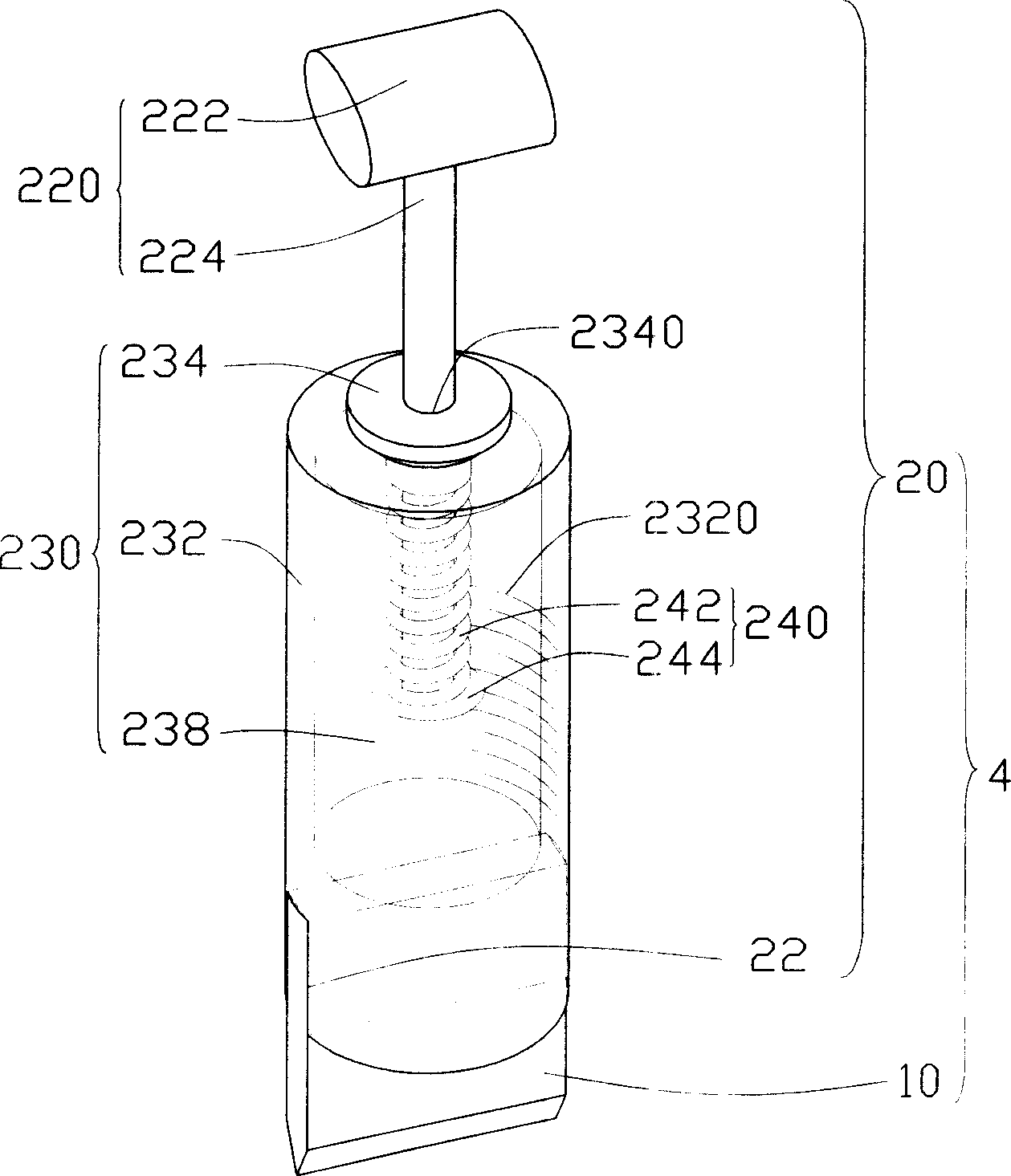

[0015] Please also refer to image 3 and Figure 4 , the ink scraper 4 includes a scraper holder 20 and a scraper head 10 , the scraper holder 20 is provided with a groove 22 to hold the scraper head 10 .

[0016] The scraper holder 20 includes a push-and-grip mechanism 220 , a casing 230 and a force control mechanism 240 , wherein the casing 230 is a hollow cylinder. The housing 230 includes a cylindrical wall 232 , a neck 234 and an inner cavity 238 , the cylindrical wall 232 has a scale 2320 , and the neck 234 has a hole 2340 longitudinally. The push-and-grip mechanism 220 includes a handle 222 and an actuating lever 224 , and the force control mechanism 240 includes a spring and a finger plate 244 .

[0017] One end of the actuating rod 224 fixes the handle 222 , and the other end passes through the hole 2340 into the inner cavity 238 . The spring 242 is longitudinally sleeved on one end of the actuating rod 224 located in the cavity 238 , and one end of the spring 242 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com