Sewing machine

A technology for sewing machines and casings, which is applied in the direction of sewing machine components, sewing equipment, sewing machine control devices, etc., and can solve problems such as drive motor starting, switch contamination, labor accidents, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

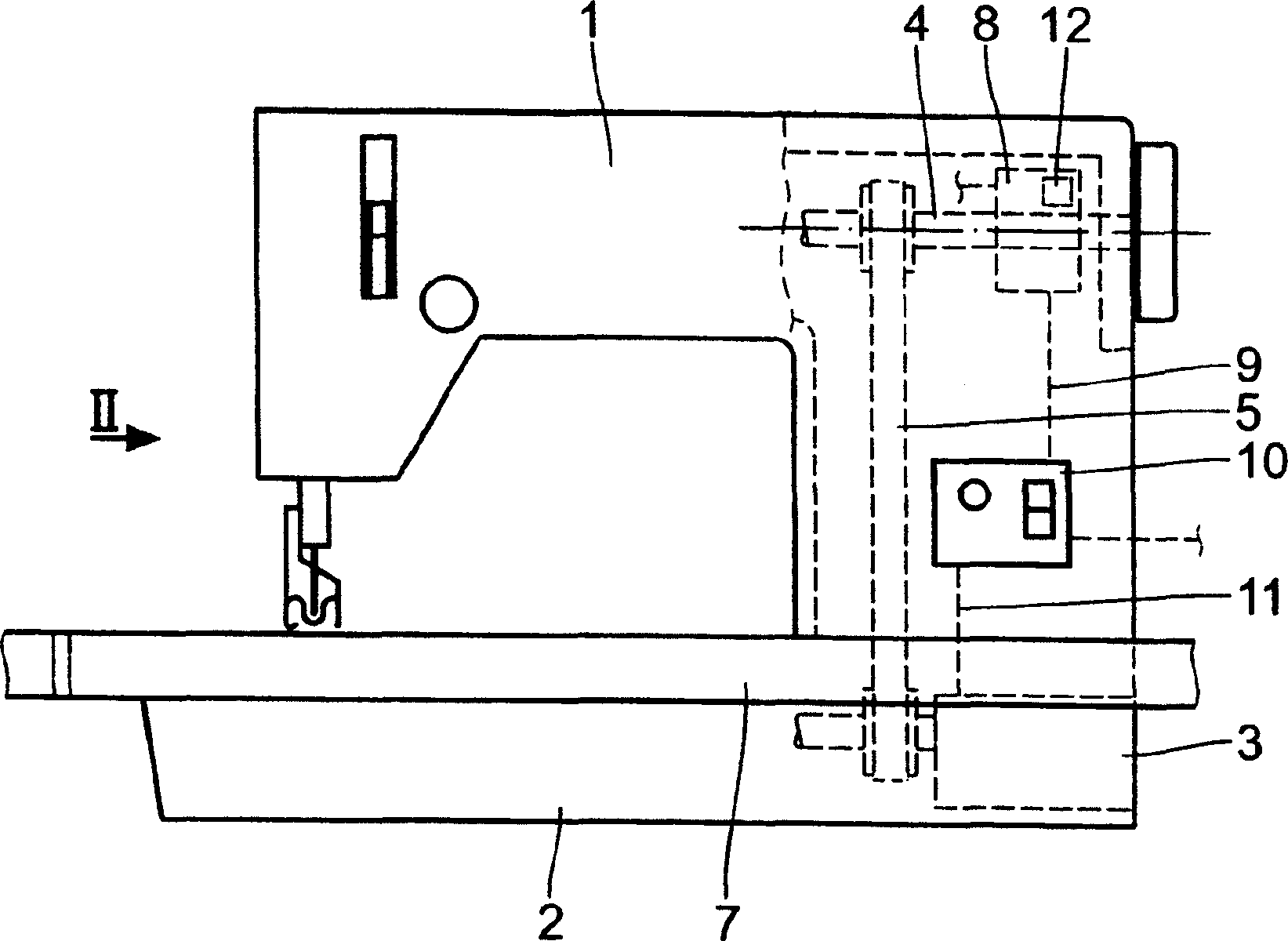

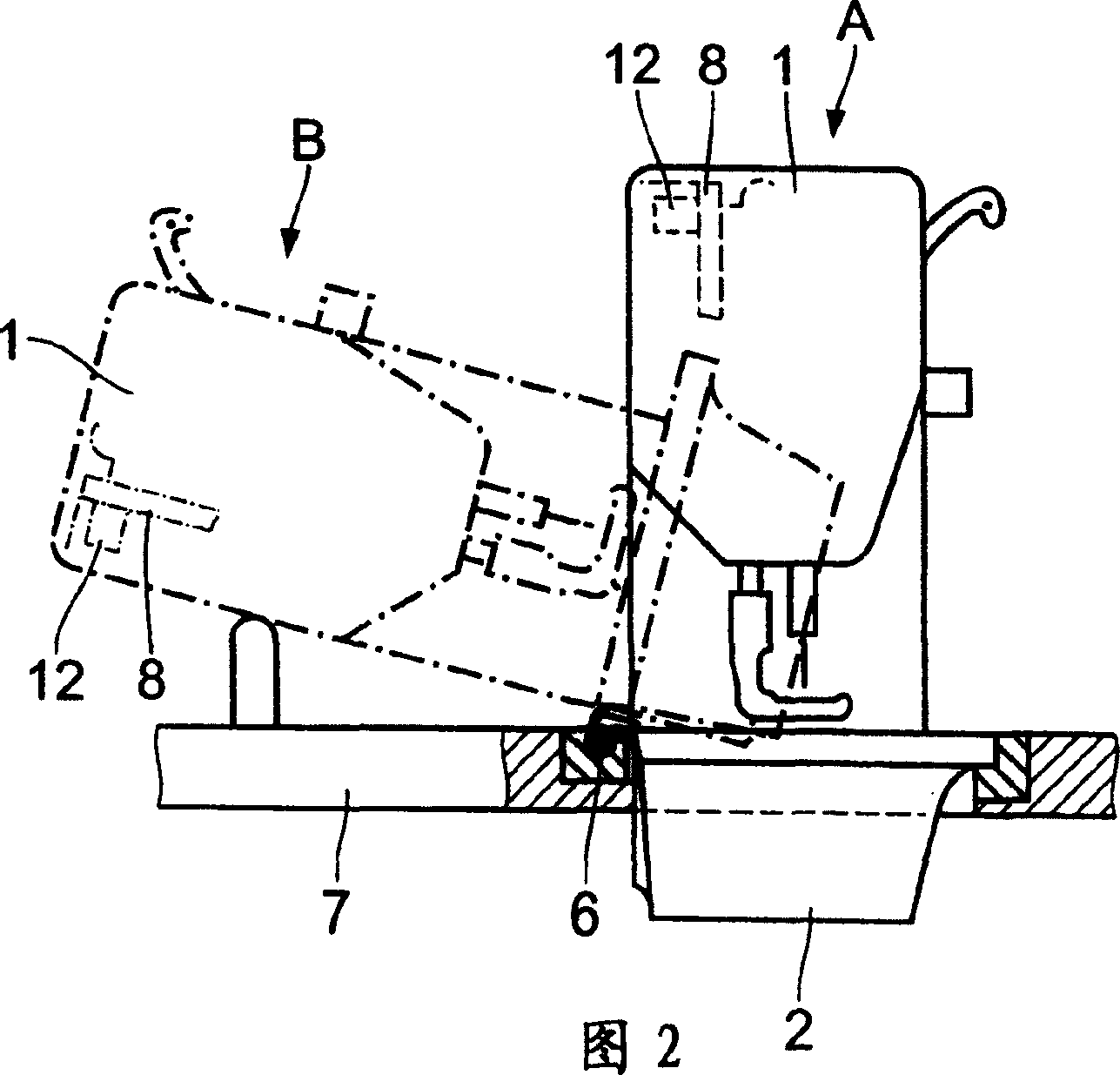

[0019] The sewing machine has a casing which is composed of an arm 1 and a base plate 2 fixed to the arm 1 and accommodates a drive system such as a drive motor 3 and an arm shaft 4 which constitutes a synchronous / positive A timing (toothed) belt 5 is connected to the main shaft of the drive motor 3 . The casings 1 , 2 are pivotably mounted on a tabletop 7 via a hinge 6 . The solid line in Fig. 2 shows the sewing machine in the vertical operating position A, while the broken line shows the sewing machine in the maintenance position B.

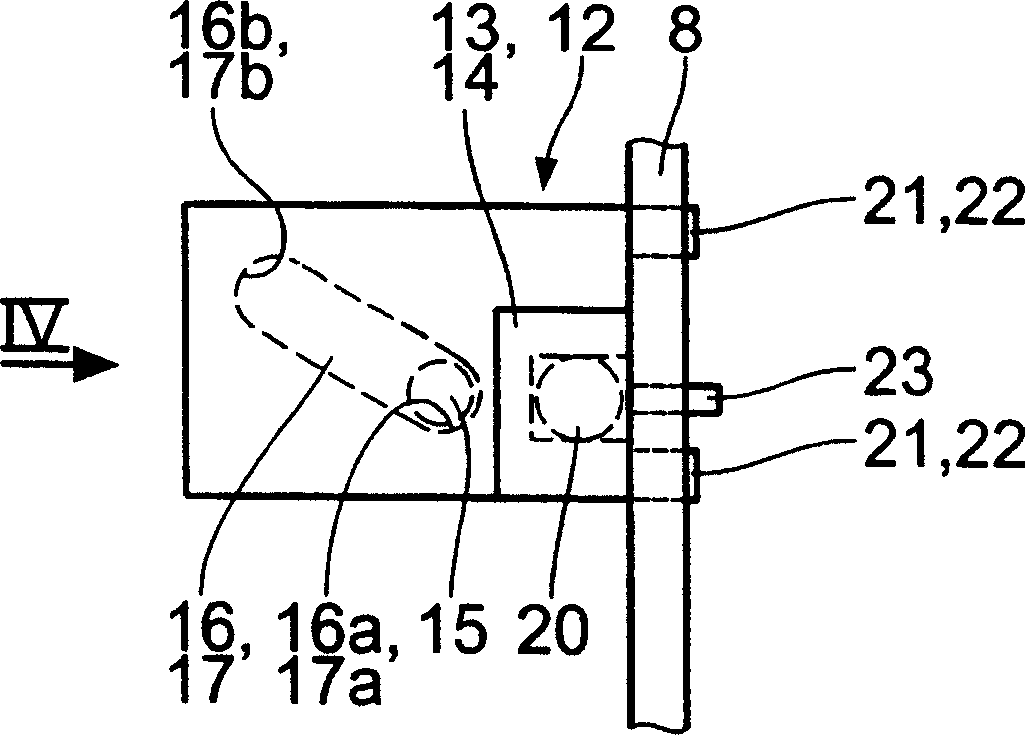

[0020] A printed circuit board 8 is arranged inside the arm 1 at the same height as the arm shaft 4; this printed circuit board is electrically connected via a wire 9 to a control system 10 which in turn is electrically connected via a wire 11 to the drive motor 3 . A protection device 12 is placed on the printed circuit board 8 ; this protection device 12 is also electrically connected to the drive motor 3 .

[0021] The protective device 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com