Relay and process for producing a relay

A relay and armature technology, applied in relays, electromagnetic relays, detailed information of electromagnetic relays, etc., can solve the problems of complex structure of relays, expensive precision manufacturing, etc., and achieve the effect of simple adjustment and precise adjustment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

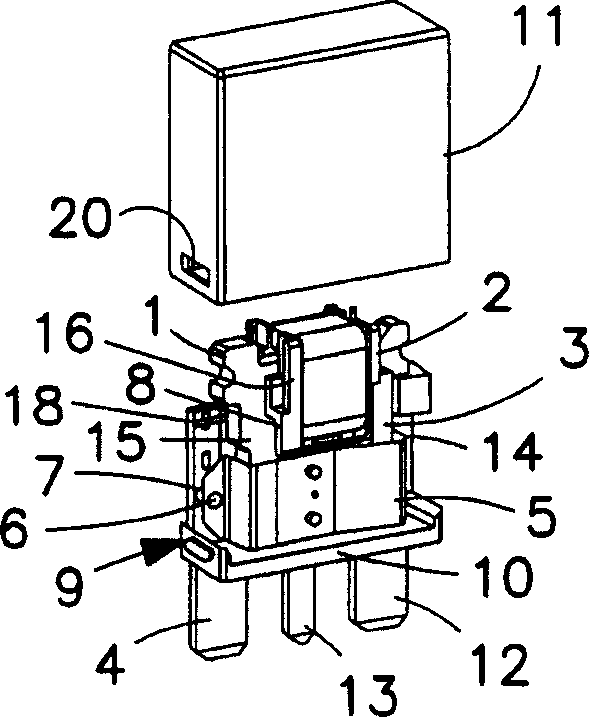

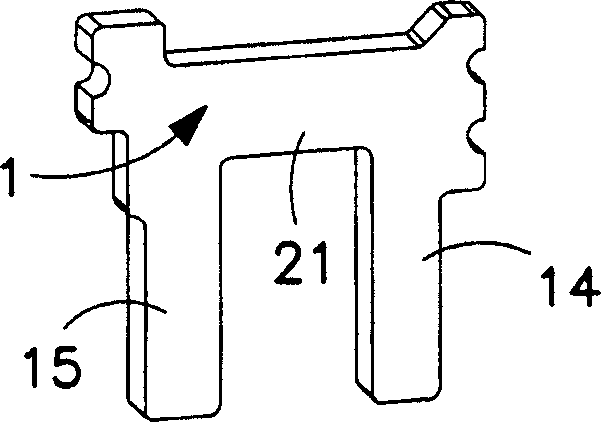

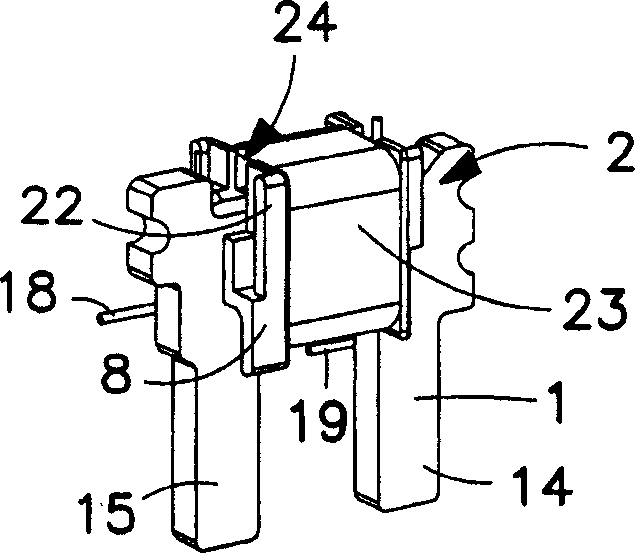

[0029] figure 1 A perspective view of the relay with the protective cover 11 raised is shown. The relay has a base 9 made of insulating material into which three contact pins 4, 12, 13 are inserted and held in place. The magnetic circuit containing the magnetic coil 2 and the U-yoke 1 is also in the base 9 . The yoke 1 has first and second yoke legs 14 , 15 , which are arranged parallel to each other and fixed in the base 9 . An L-shaped armature 3 rests against the first yoke leg 14 . On the top of the base 9 , a movable contact in the form of an elastic contact piece 5 is placed parallel to the substrate 10 . The right end of the elastic contact piece 5 is fixed to the second contact pin 12, such as by a rivet. The elastic contact piece 5 is fixed together with the armature 3 in its central area. The other free movable end of the elastic contact piece is combined with the first contact pin 4 . The magnetic coil 2 has a coil housing 16 on which a support projection 8 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com