Collapsible container from plastic, and method and mold for the manufacture thereof

A container and plastic technology, applied in the field of foldable containers, can solve problems such as the vulnerability of containers, achieve the effects of large bearing capacity, improved centralized folding, and increased load bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

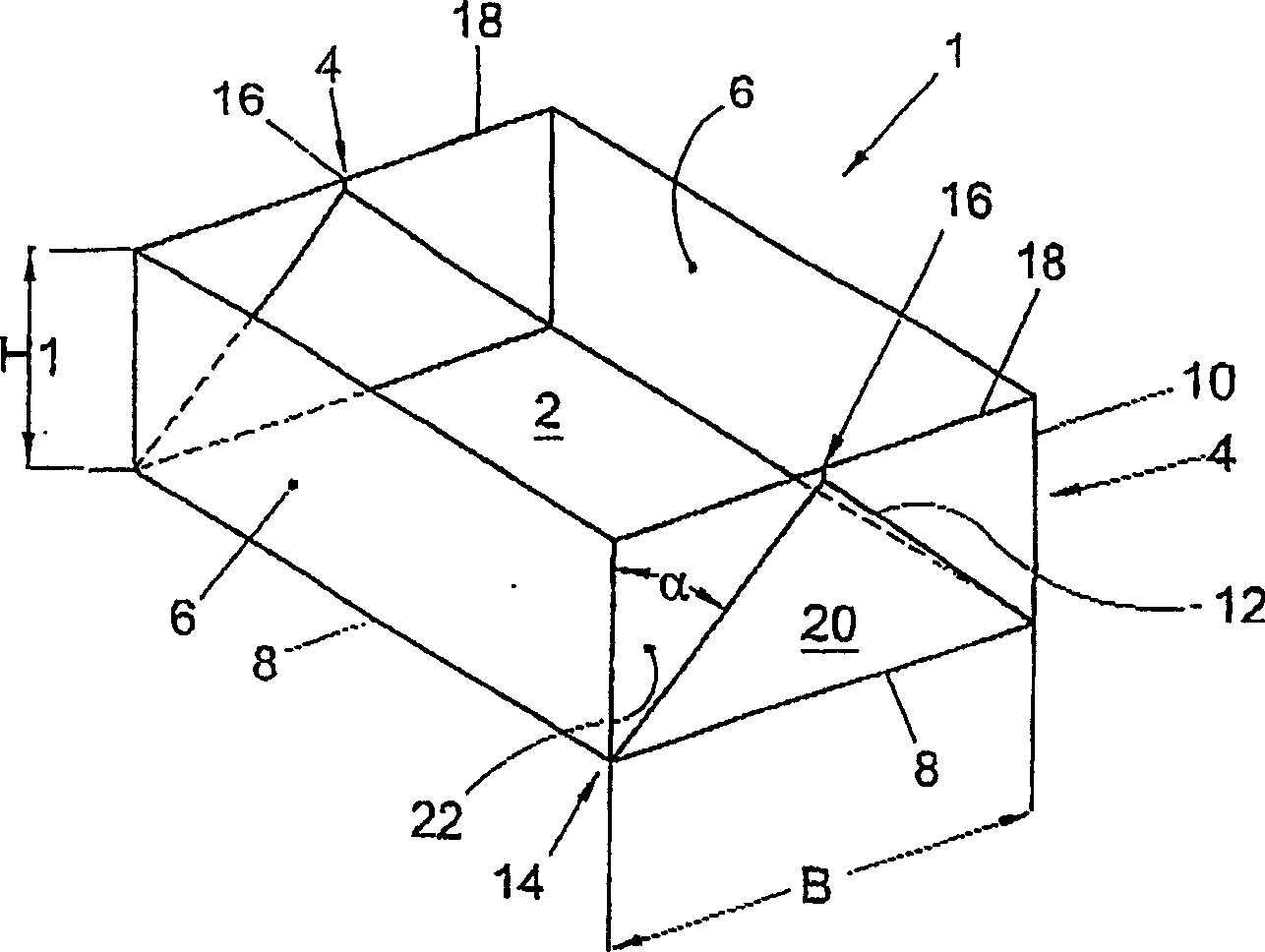

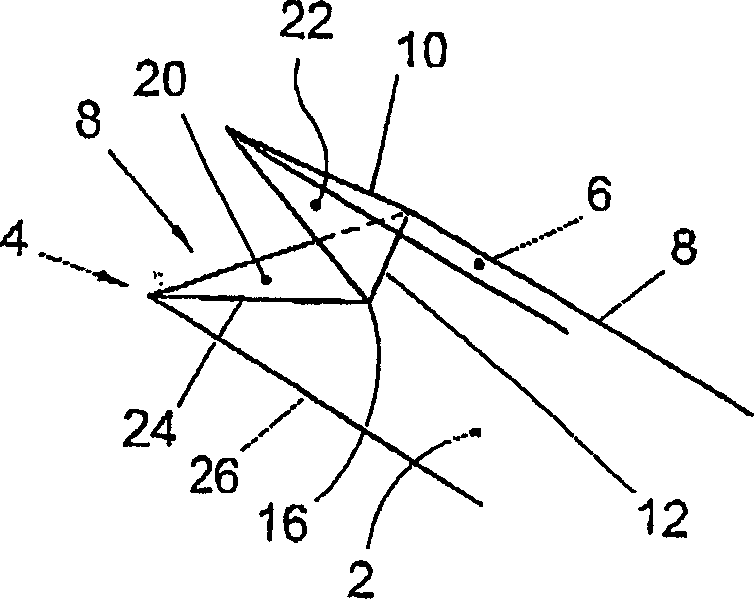

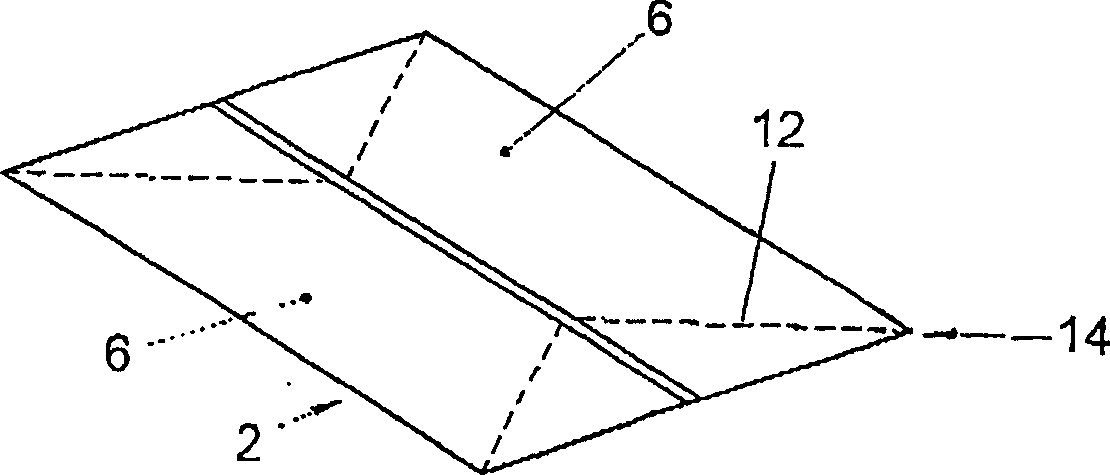

[0040]In the description and drawings, the illustrated exemplary embodiments of the invention should not be considered limiting in any way. The invention is described on the basis of a substantially rectangular container, at least one container with a rectangular base. Naturally, this can also be a quadrangle, and at the same time, further, a polygonal bottom surface, such as a hexagonal, octagonal or dodecagonal surface, can also be used without departing from the idea of the present invention. According to the invention, the containers included in this description are all formed in one piece by injection moulding, while, however, prior to insertion into the mould, plastic inserts can be inserted, such as films for in-mould marking, for forming Films of film hinges or the like, fastening means or the like, which are wrapped and fixed by melting and / or by injection molding and incorporated in the container.

[0041] In the exemplary embodiments shown, each time a substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com