Gas and solid granular reaction method

A technology of solid particles and gases, applied in chemical instruments and methods, chemical/physical processes, etc., can solve the problems of large consumption of carried gases and reactive substances, uneven product properties, high labor intensity, etc., and achieve easy large-scale industrial Easy application, completely closed transportation, and the effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

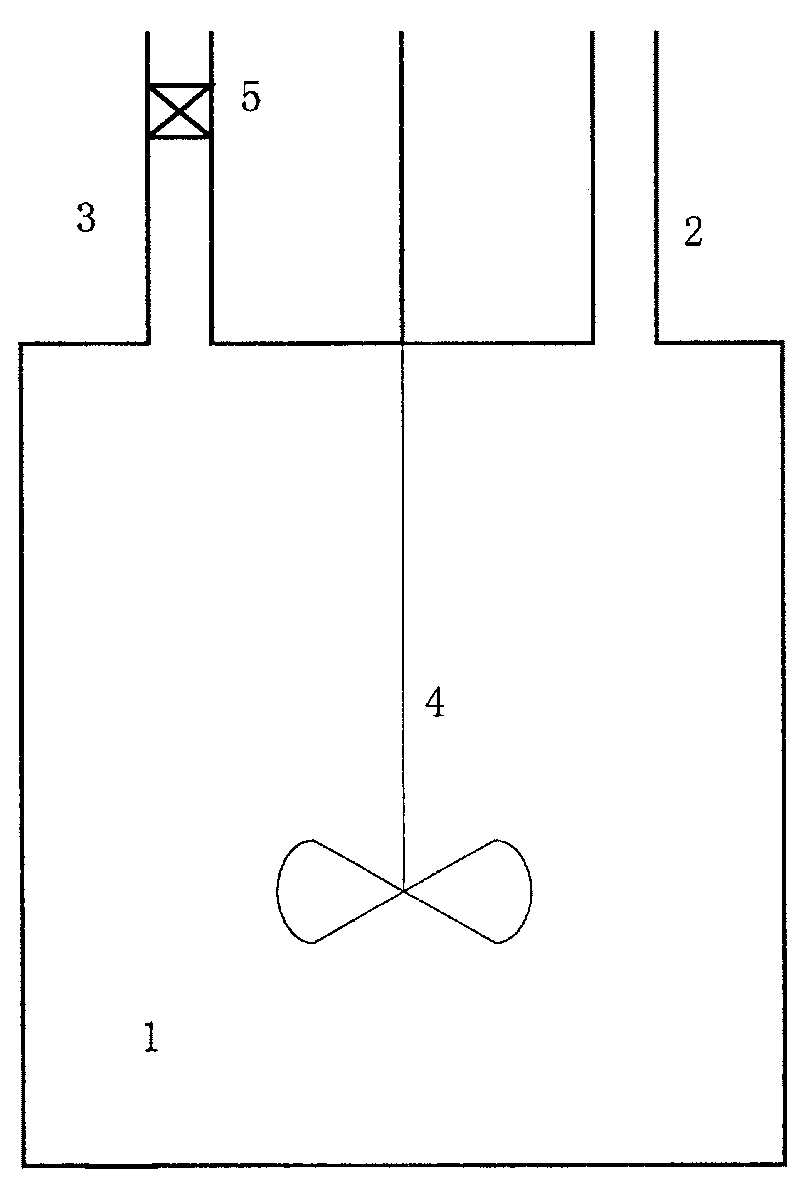

[0019] The first specific embodiment of the present invention is as follows figure 1 shown. Described reaction equipment comprises a reactor 1, a feed port 2 and a gas outlet 3, also has a stirrer 4 inside the reactor 1, and wherein, a gas-solid separator 5 is installed on the gas outlet 3, gas The hole diameter and porosity of the holes contained in the solid separator 5 ensure that the gas can pass through but the solid particles cannot pass through. The stirring rod of the stirrer 4 stretches out of the reaction kettle 1, and the place where the stirring rod contacts the reaction kettle 1 is airtight, so that the reaction kettle 1 is not connected to the outside world.

[0020] When carrying out the reaction of gas and solid particles, load the solid particles from the feed port 2, start the agitator 4, and add the gas that reacts with the solid particles or the material that can generate the gas that reacts with the solid particles, and the feed port 2 And air outlet 3 ...

Embodiment approach 2

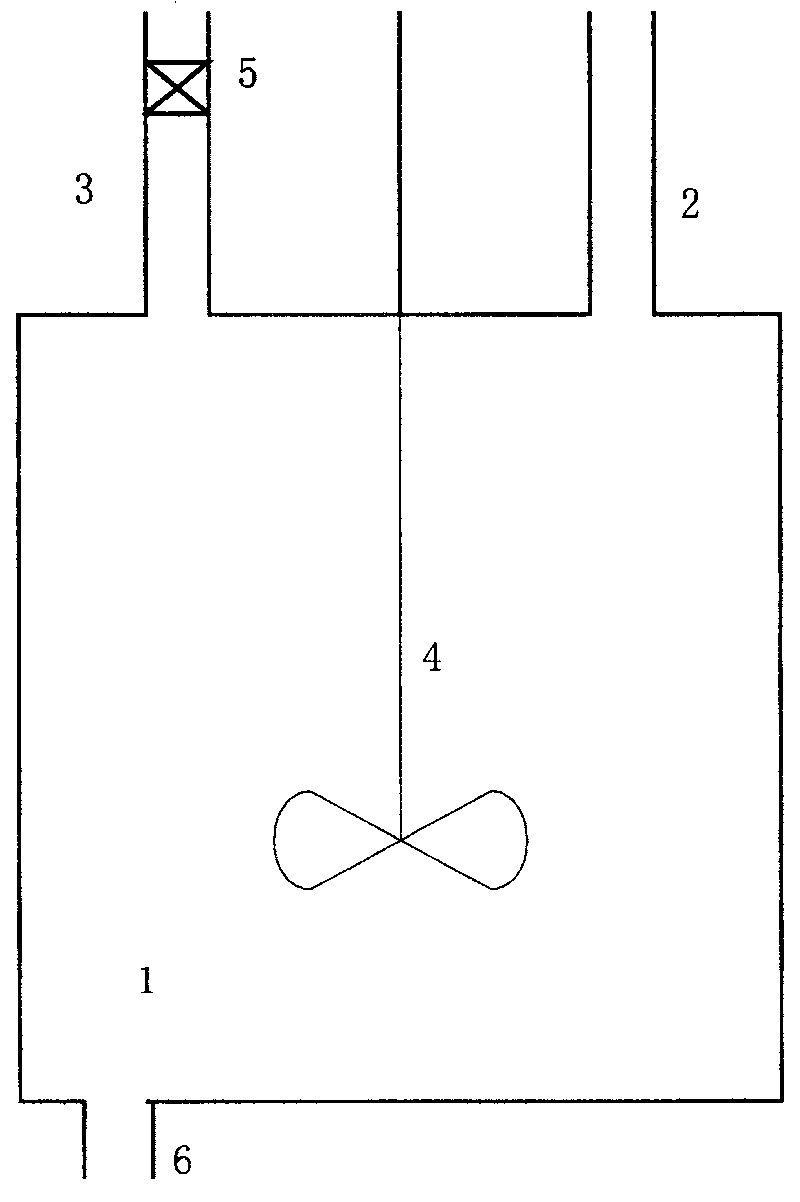

[0022] The second specific embodiment of the present invention is as figure 2 shown. The reaction device includes all components of the first embodiment, and also includes an air inlet 6 . The air inlet 6 can be located at any position of the reactor 1 , preferably, the feed inlet 2 and the gas outlet 3 are located at the upper part of the reactor 1 , and the air inlet 6 is located at the lower part of the reactor 1 . The air inlet 6 is used to add gas or gasifiable material that reacts with solid particles. With the gas inlet 6, the gas or the substance that can generate the gas reacting with the solid particles is fed through the gas inlet 6, and the feed inlet 2 is specially used for adding the solid particles, and the operation is more convenient.

[0023] During the reaction between the gas and the solid particles, the solid particles are loaded from the feed port 2, the agitator 4 is started, and the feed port 2 and the gas outlet 3 are sealed. Add the gas that react...

Embodiment approach 3

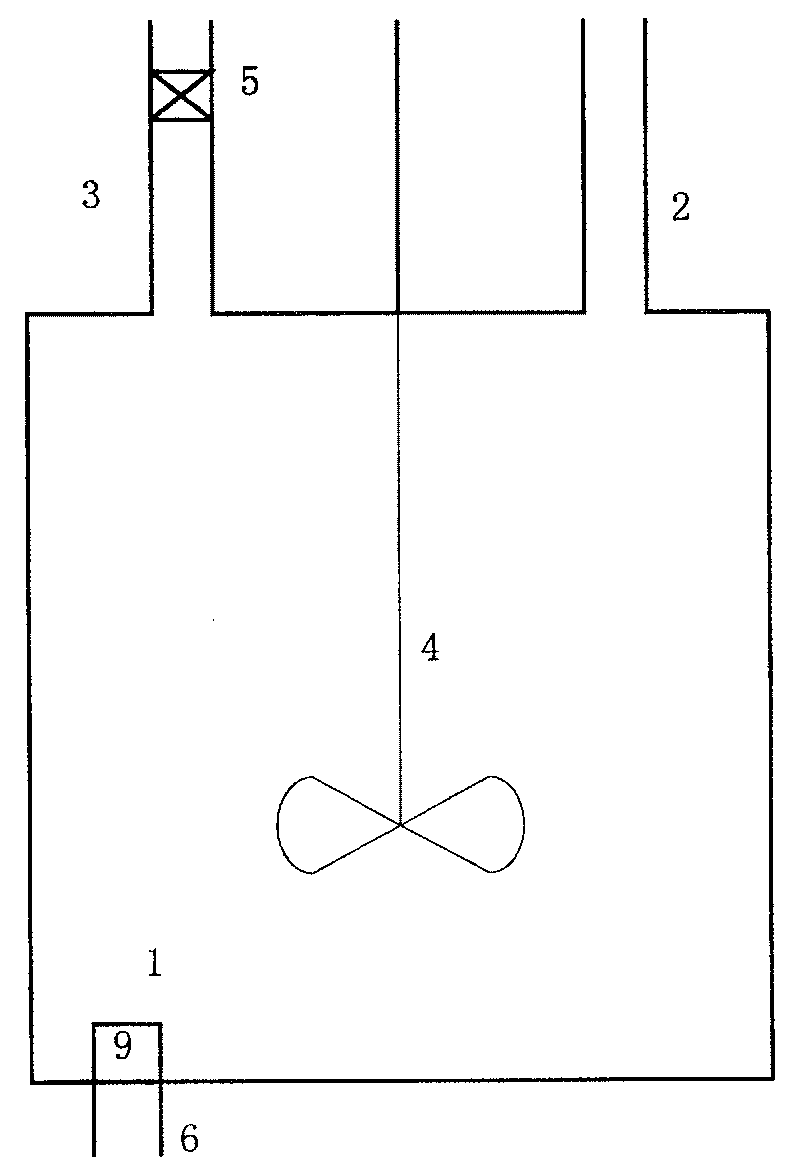

[0025] The third specific embodiment of the present invention is as image 3 shown. The reaction equipment includes all the components of the second specific embodiment, and a gas distributor 9 is installed on the top of the air inlet 6, and the top of the gas distributor 9 is on a plane or at the height of the bottom of the reactor 1. On the plane where the bottom of the reactor 1 is located. The function of the gas distributor is to enable the gas to enter the reaction kettle 1 continuously and evenly, and at the same time, ensure that solid particles do not enter the pipeline connected to the air inlet 6 .

[0026] When carrying out the reaction of gas and solid particles, the solid particles are loaded from the feed port 2, the feed port 2 and the gas outlet 3 are sealed, the agitator 4 is started, and the feed port 2 is sealed. Add the gas that reacts with the solid particles or the material that can generate the gas that reacts with the solid particles from the gas inl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com