Laser beam processing machine

A laser beam and processing machine technology, applied in metal processing, laser welding equipment, metal processing equipment, etc., can solve problems such as unsatisfactory productivity and achieve the effect of high-efficiency laser beam processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Preferred embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

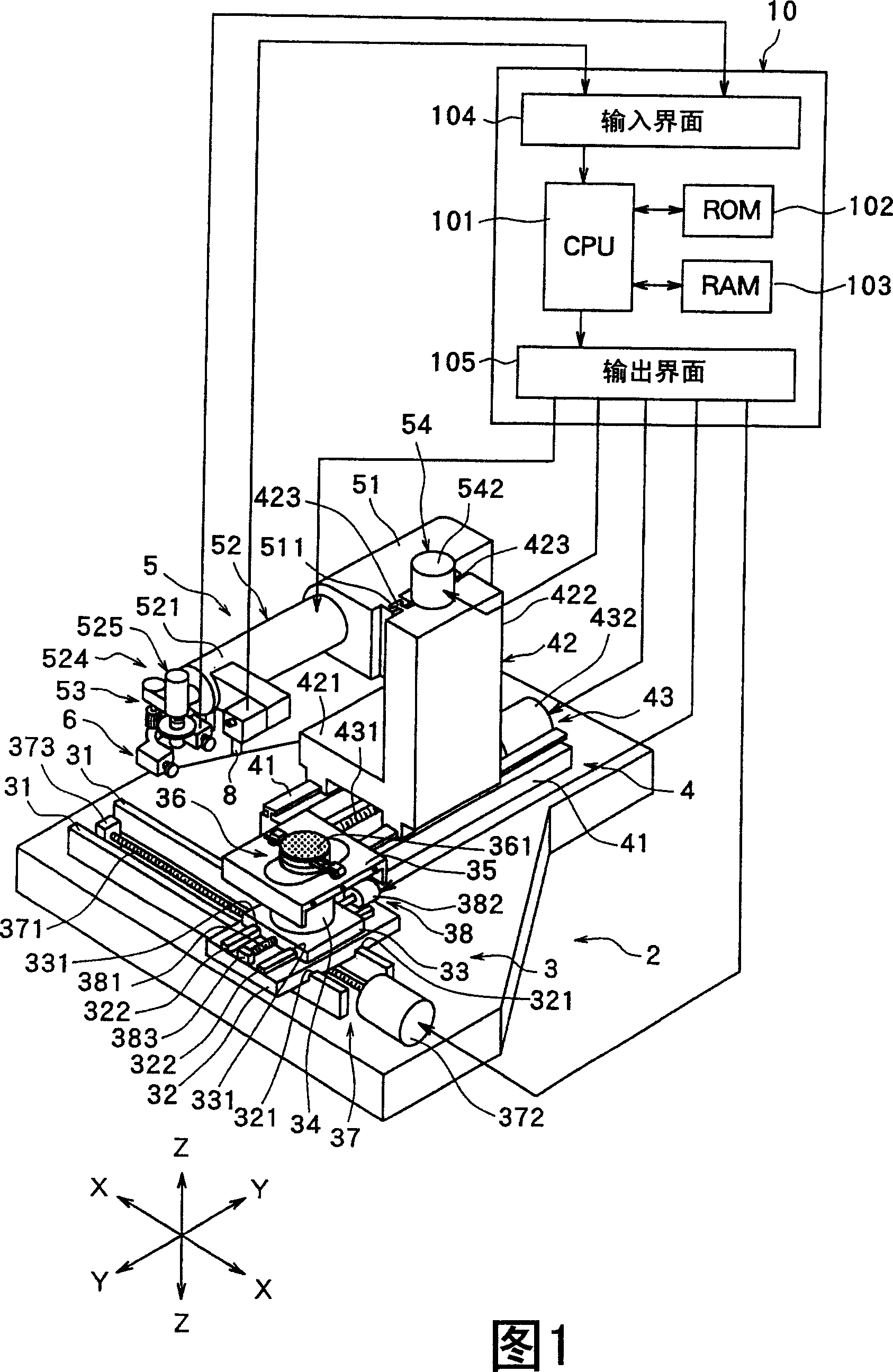

[0027] Figure 1 is a perspective view of a laser beam processing machine constructed in accordance with the present invention. The laser beam processing machine shown in Fig. 1 comprises a stationary base 2, a chuck table mechanism 3 for holding a plate-shaped workpiece, a laser beam applying unit supporting mechanism 4, and a laser beam applying unit 5, wherein the chuck table mechanism 3 is Mounted on the stationary base 2 in a manner that can move along the processing feed direction indicated by the arrow X, the laser beam applying unit support mechanism 4 can be moved along the direction indicated by the arrow Y in the direction perpendicular to the direction indicated by the arrow X. It is installed on the stationary base 2 in a manner of moving in the direction of 100°, and the laser beam applying unit 5 is installed on the support mechan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com