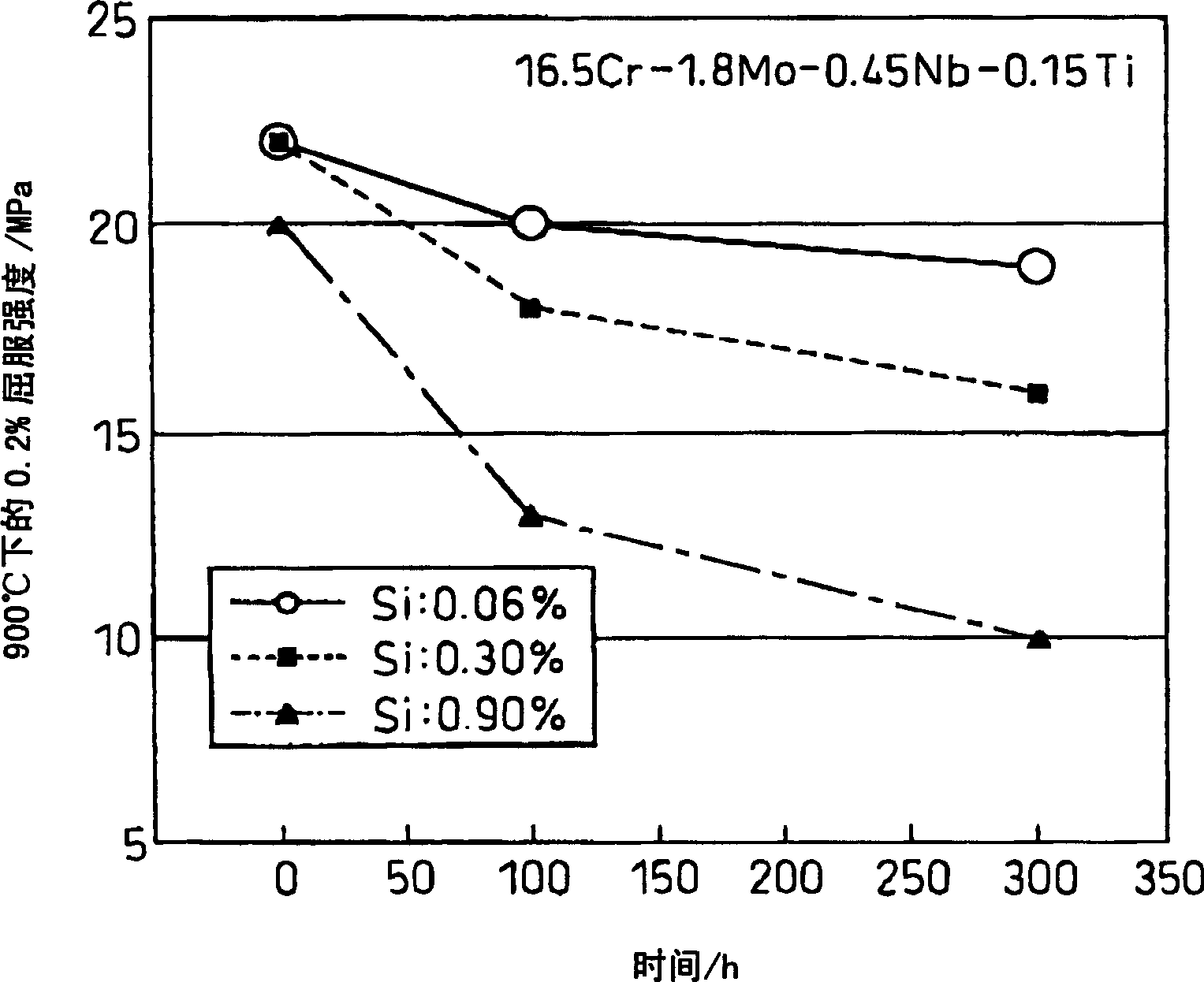

Ferrite stainless steel for automobile exhaust system member superior in thermal fatigue strength

An automobile exhaust system, thermal fatigue technology, applied in the direction of exhaust devices, sports accessories, engine components, etc., can solve the problems of difficult deoxidation, precise control of components, thermal fatigue characteristics without any solution, thermal fatigue characteristics decline, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] A 50 kg steel ingot having the chemical composition shown in Table 1 was melted in a vacuum melting furnace, heated from 1150°C to 1280°C, and hot-rolled to obtain a hot-rolled sheet having a thickness of 5 mm. The hot rolling start temperature at this time is 1100°C to 1250°C, and the hot rolling end temperature is 800°C to 900°C. Thereafter, the hot-rolled sheet was heated from 900° C. to 1000° C. and held for 60 seconds to perform hot-rolled sheet annealing. Further, cold rolling was performed to form a 2 mm thick cold rolled sheet, then heated to 1050° C., held for 60 seconds for final annealing, and the steel sheet obtained by pickling with hydrofluoric acid was used as a test steel.

PUM

| Property | Measurement | Unit |

|---|---|---|

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

| directional tensile yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com